Copolymerized phosphorus-nitrogen macromolecular intumescent flame retardant modified layered nano zirconium phosphate as well as preparation method and application thereof

An intumescent flame retardant, layered nanotechnology, applied in the field of zirconium phosphate, can solve the problems of ineffective regulation, high content of hindered amine groups, limited flame retardant efficiency, etc., to improve catalytic carbonization performance, overcome easy migration , the effect of excellent flame retardant performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

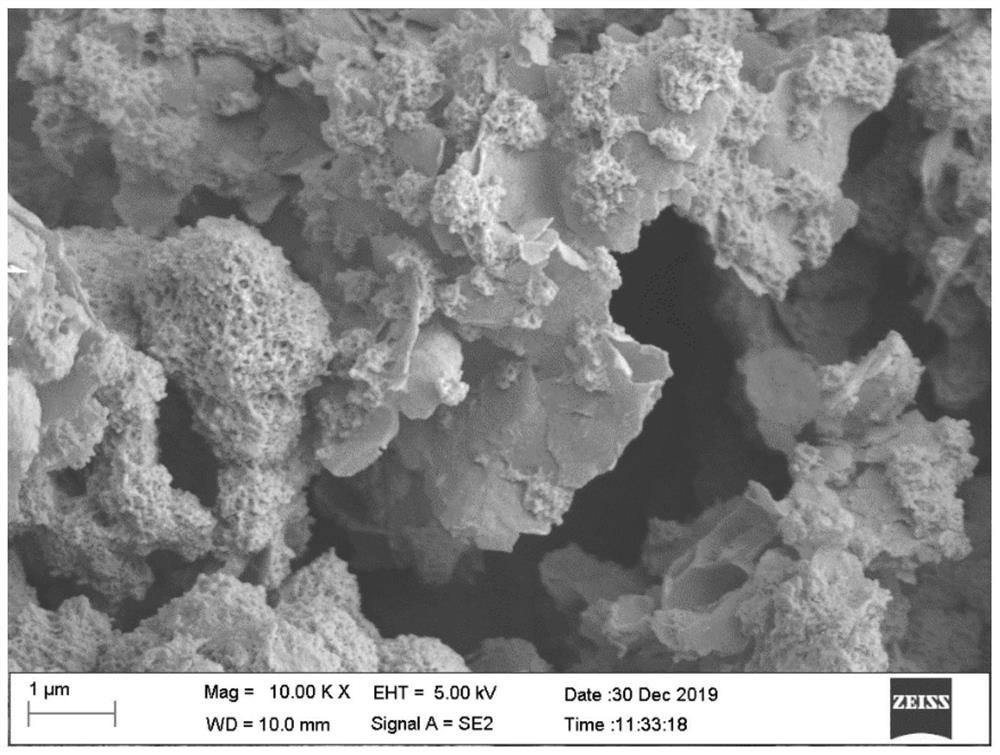

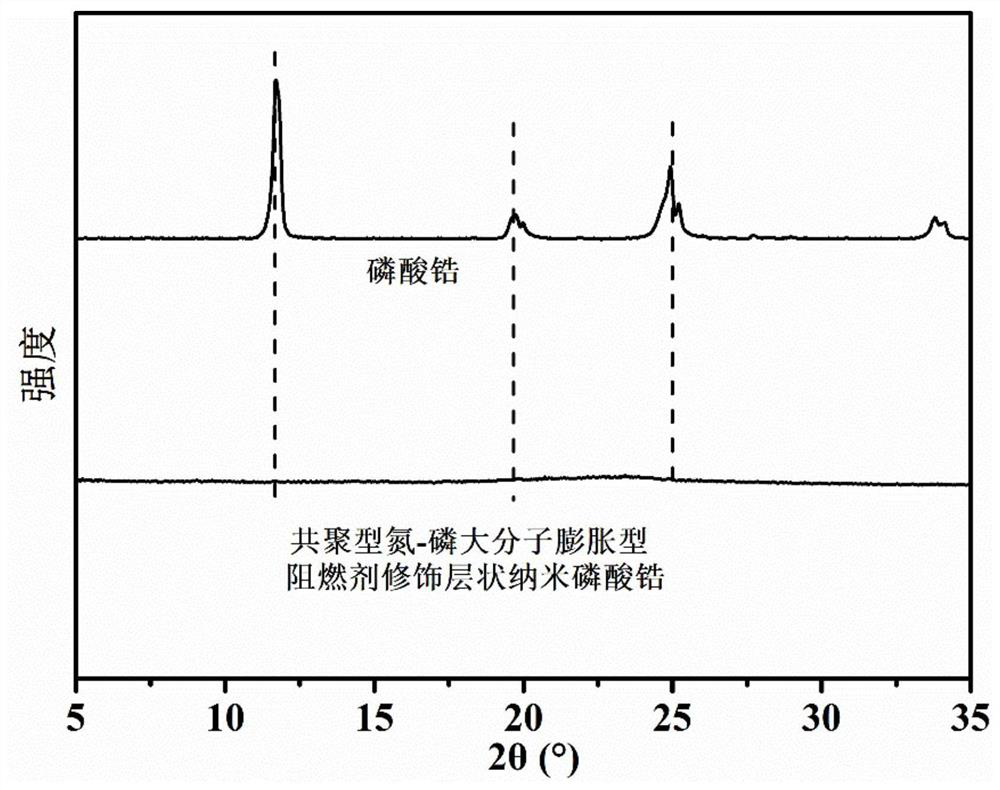

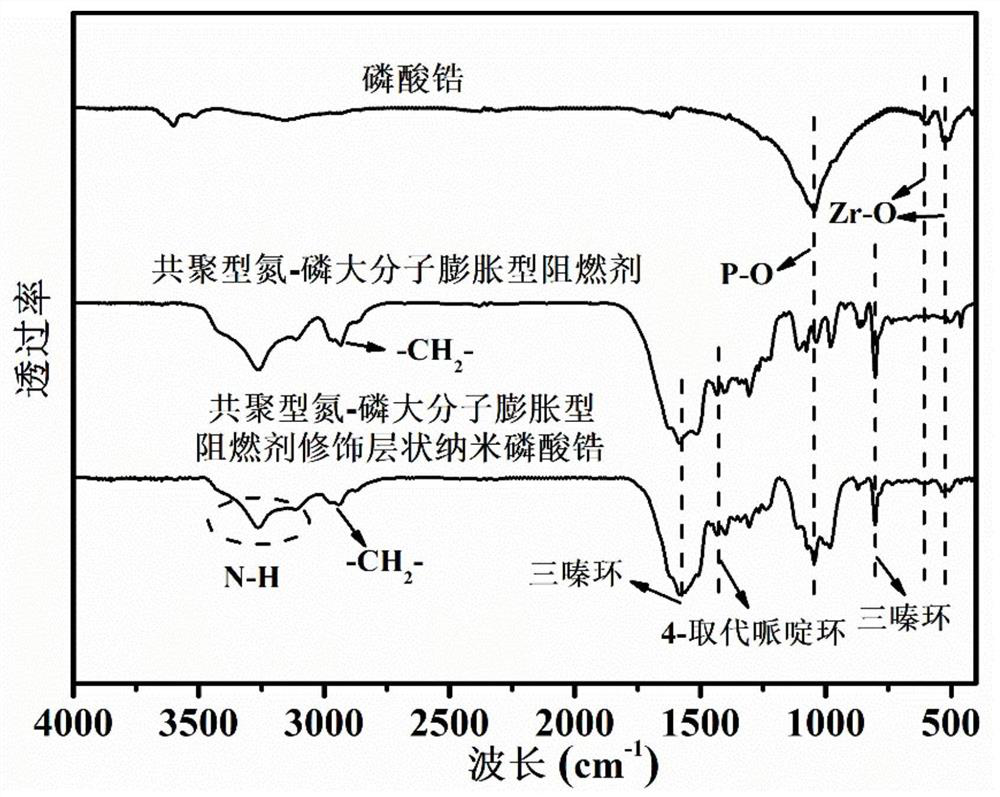

[0035] Preparation method of layered nanophosphate phosphosphate in a copolymerized phosphorus-nitrogen moxic expansion flame retardant, including the following steps:

[0036] 1) Synthesis of copolymerized phosphorus-nitrogen moxic expansion flame retardants: Under 5 ° C, 36.90 g of three-mouth flask, 35.82 g of PEPA, 0.75 g T152 and 250 mL of acetonitrile were added to 350R. The MIN speed was stirred at 15 min; 20.20 g of triethylamine was slowly added dropwise, and the dropwax time was 1.5 h. After the drop was completed, the reaction was continued for 4 h; then, 12.00 g of ethylenediamine was continued after the temperature was raised to 55 ° C. 20.20 g of a mixture of triethylamine, a dropwate of 1.5 h, and the reaction was continued after 6 h after completion of the drop. Finally, heated to 95 ° C, and 20.20 g of triethylamine reflux reaction was added 6 h. After completion of the reaction, the mixture was filtered, washed, dried to obtain a nitrogen-phosphorus macromolecula...

Embodiment 2

[0041] Preparation method of layered nanophosphate phosphosphate in a copolymerized phosphorus-nitrogen moxic expansion flame retardant, including the following steps:

[0042] 1) Copolymerized nitrogen-phosphorus moxic expansion flame retardant synthesis: Under 0 ° C, 36.90 g of TME cyanin, 35.64 g PEPA, 1.50 g T152 and 250 mL of toluene were added to 500 ml of toluene. The MIN speed was stirred at 10 min; 23.70 g of pyridine was slowly added dropwise, and the drip time was 2 h. After the drop was completed, the reaction was continued for 5 h; then, 14.40 g of ethylenediamine and 15.82 g of pyridine were continued after the temperature increased to 60 ° C. The mixture was mixed with a dropwise time of 2 h, and the reaction was continued for 8 h after completion of the drop. Finally, the temperature was warmed to 100 ° C, and 23.70 g of a pyridine reflux reaction was added dropwise for 9 h. After completion of the reaction, the mixture was filtered, washed, dried to obtain a nitro...

Embodiment 3

[0046] Preparation method of layered nanophosphate phosphosphate in a copolymerized phosphorus-nitrogen moxic expansion flame retardant, including the following steps:

[0047] 1) Synthesis of copolymerized phosphorus-nitrogen moxic expansion flame retardants: Under 10 ° C, 36.90 g of TME cyanide, 35.29 g of PEPA, 2.97 g T152 and 250ml 1, 4- Dioxin ring, mechanically stirred at 200R / min speed to make it dispersed uniform; slowly drop 24.24 g of triethylamine, the dropwate is 2 h, and the reaction is continuously reacted after 3 hours after the drop; then, the temperature increases to 40 ° C continued A mixture of 12.00 g of ethylenediamine and 24.24 g of triethylamine were added dropwise, and the dropwate was 2 h, and the reaction was continued for 8 h after drying. Finally, the temperature was warmed to 100 ° C, and 24.24 g of triethylamine reflux reaction was added to 9 h. After completion of the reaction, the mixture was filtered, washed, dried to obtain an macromolecularly e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com