A pure metal/high-entropy alloy nano-multilayer film with controllable phase transition properties and its preparation method

A nano-multilayer, high-entropy alloy technology, applied in metal material coating process, nanotechnology, coating and other directions, can solve the problems of dislocation plug-in interface damage, increased strength, low deformation ability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

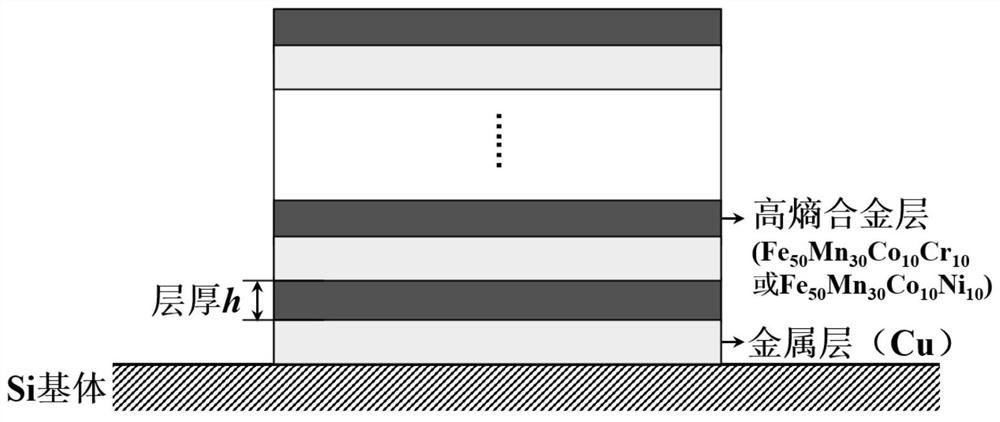

[0047] A preparation method of a pure metal / high-entropy alloy nano-multilayer film with controllable phase transition characteristics of the present invention comprises the following steps:

[0048] Step 1: cleaning and drying the surface of the silicon substrate, and removing the oxide layer on the surface of the silicon substrate by using hydrofluoric acid aqueous solution on the dried silicon substrate;

[0049] Specifically, one side of the silicon substrate is polished, and then the polished one side of the silicon substrate is ultrasonically cleaned in acetone and ethanol for at least 10 minutes, and then quickly dried with warm air to make the surface of the silicon substrate clean, free of stains, and Dust adheres, the roughness is below 0.5-0.8nm, then soak the dried silicon substrate in hydrofluoric acid aqueous solution for at least 5min, and dry after soaking, wherein the concentration of hydrofluoric acid aqueous solution is 35wt.%-45wt.% .

[0050] Step 2: In a...

Embodiment 1

[0060] Present embodiment 1 is implemented under the following implementation conditions and technical requirements:

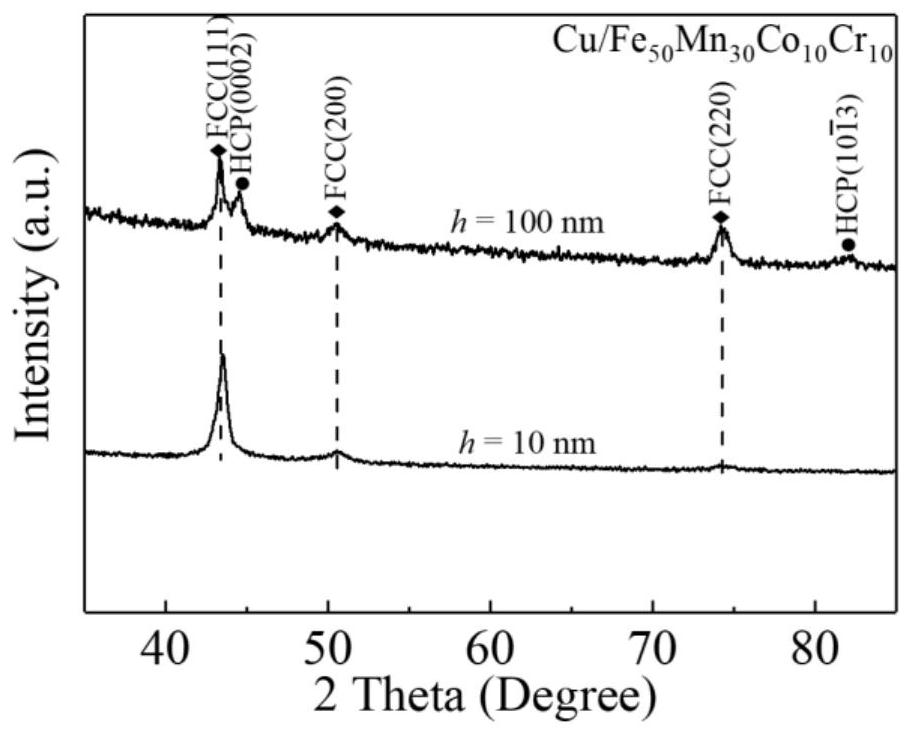

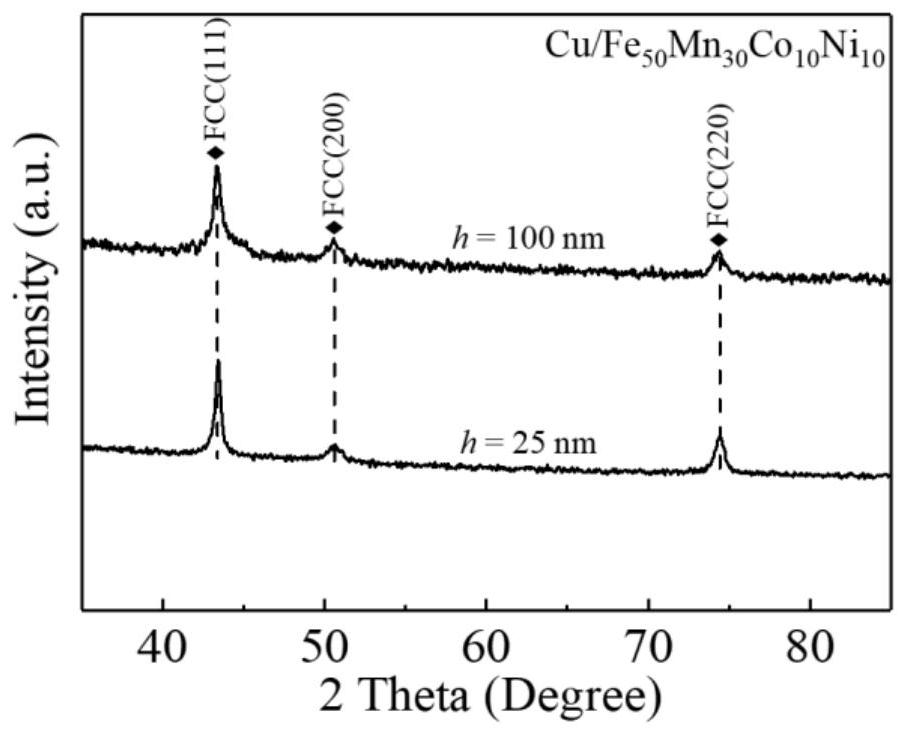

[0061] Firstly, the silicon substrate was ultrasonically cleaned in analytical pure acetone and ethanol for 10 minutes each, and then quickly dried with warm air. Then soak the silicon substrate in hydrofluoric acid with a concentration of 45wt.% for 5 minutes, remove the oxide film and dry it quickly; then fix the silicon substrate on the substrate, and automatically send it into the magnetron sputtering vacuum coating chamber mechanically and automatically. To the vacuum degree of the background at 1.0×10 -4 Pa. The pure metal (Cu) / high-entropy alloy (Cu / Fe 50 mn 30 co 10 Cr 10 ) nano multilayer film, Cu target (purity 99.99wt.%) and Fe 50 mn 30 co 10 Cr 10 The target (purity 99.95wt.%) adopts DC power supply, the power is 200W, the deposition pressure is set to 1.0Pa, the deposition temperature is room temperature, the substrate rotation speed is 1...

Embodiment 2

[0063] This embodiment 2 is implemented under the following implementation conditions and technical requirements:

[0064] First, ultrasonically clean the silicon substrate in pure acetone and ethanol for 10 minutes each, and then quickly dry it with warm air; then soak the silicon substrate in hydrofluoric acid with a concentration of 40wt.% for 8 minutes, remove the oxide layer and then dry it quickly ; Then fix the silicon substrate on the base plate, mechanically and automatically send it into the magnetron sputtering vacuum coating chamber, and pump it until the vacuum degree of the background is 1.0×10 -4 Pa;

[0065] Then magnetron sputtering is used to deposit pure metal (Cu) / high entropy alloy (Cu / Fe 50 mn 30 co 10 Cr 10 ) nano multilayer film, Cu target (purity 99.99wt.%) and Fe 50 mn 30 co 10 Cr 10 Targets (purity 99.95wt.%) are DC power supply, the power is 200W, the deposition pressure is set to 0.8Pa, the deposition temperature is room temperature, the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com