A preparation method of gel electrolyte and a preparation method of supercapacitor

A gel electrolyte and supercapacitor technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrolytes, etc., can solve the problems of poor cycle performance, low ionic conductivity of gel electrolytes, complicated preparation processes, etc., so as to reduce residual , excellent cycle stability, the effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An embodiment of the present invention provides a method for preparing a gel electrolyte, comprising the following steps:

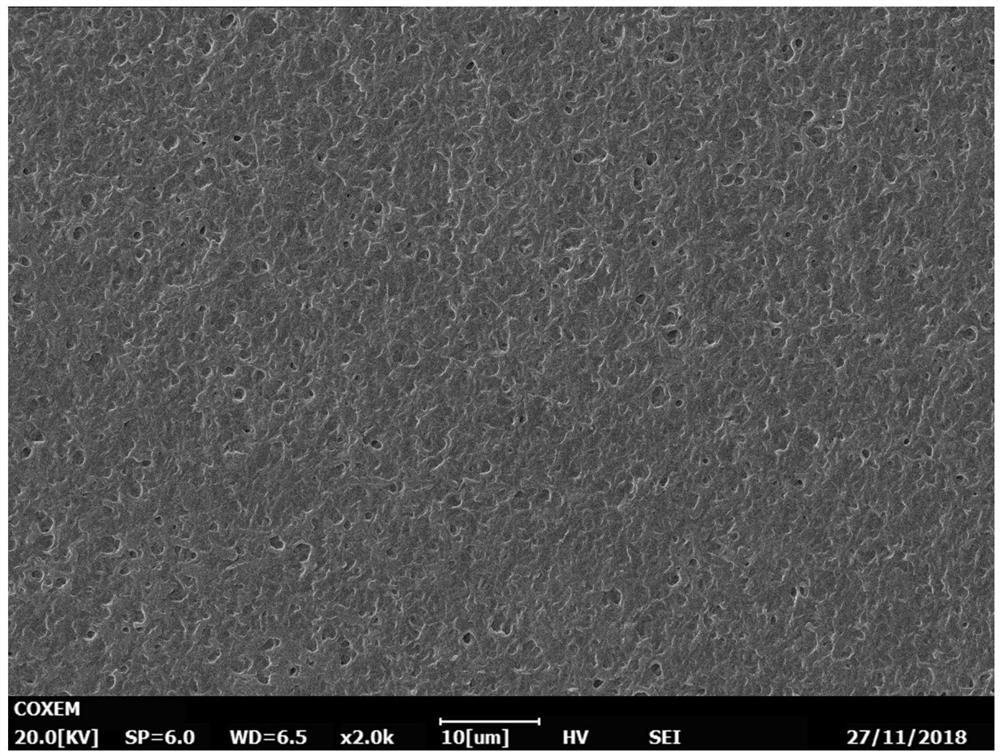

[0028] Dissolve PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) in NMP (N-methylpyrrolidone) / acetone mixed solvent, apply the obtained PVDF-HFP glue evenly on the flat substrate, separate and dry to obtain the electrolyte matrix;

[0029] The electrolyte matrix is combined with the electrolyte solution to obtain a gel electrolyte.

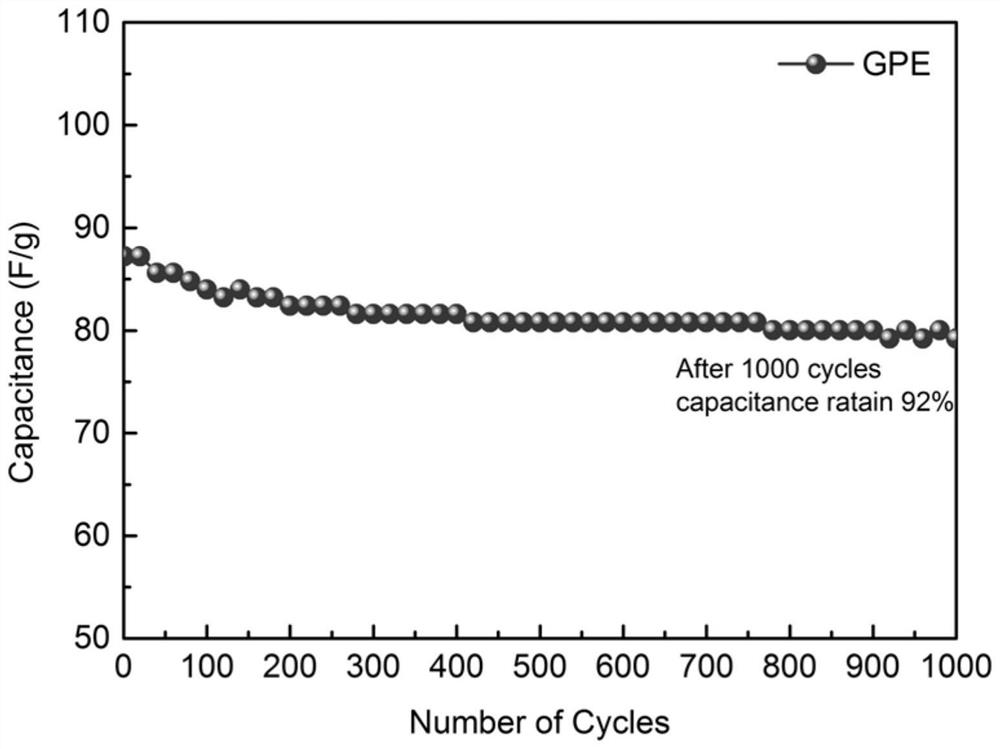

[0030] The preparation method of the gel electrolyte uses PVDF-HFP as the electrolyte matrix, and its ionic conductivity is >10 -3 S / cm, the assembled supercapacitor was cycled for 1000 cycles at a current density of 1A / g, and the capacity retention rate was 93%, showing excellent cycle stability. As an improvement of the present invention, a mixed solvent of NMP / acetone is used to dissolve PVDF-HFP, which can effectively disperse PVDF-HFP, and at the same time effectively reduce the residue of solvent in the...

Embodiment 1

[0055] This embodiment is used to illustrate the supercapacitor disclosed in the present invention and its preparation method, including the following steps:

[0056] (1) Glue preparation: Dissolve PVDF-HFP (molecular weight 40w) with a mass fraction of 15wt% in a mixed solvent of NMP / acetone to obtain PVDF-HFP glue, wherein the mass ratio of NMP:acetone is 1.5:1, and Stir for 24 hours, and vacuumize to remove the air bubbles in the PVDF-HFP glue;

[0057] (2) Substrate preparation: Use the coating machine to coat the PVDF-HFP glue solution obtained in step (1) evenly on the glass substrate coated with polyimide, and after drying for 48h under natural conditions, separate the substrate from the glass substrate , punched into a preset size, and dried under vacuum for 6 hours to obtain an electrolyte matrix;

[0058] (3) Preparation of gel electrolyte: Prepare a special electrolyte for supercapacitors in an argon atmosphere, immerse the electrolyte matrix obtained in step (2) i...

Embodiment 2

[0063] This embodiment is used to illustrate the supercapacitor disclosed in the present invention and its preparation method, including the following steps:

[0064] (1) Glue preparation: Dissolve PVDF-HFP (molecular weight 45w) with a mass fraction of 20wt% in a mixed solvent of NMP / acetone to obtain PVDF-HFP glue, wherein the mass ratio of NMP:acetone is 0.5:1, at room temperature Stir for 24 hours, and vacuumize to remove the air bubbles in the PVDF-HFP glue;

[0065] (2) Substrate preparation: use the coating machine to apply the PVDF-HFP glue solution obtained in step (1) evenly on the glass substrate coated with polyimide, dry under natural conditions for 60h, after that, the substrate and glass The substrate is separated, punched into a preset size, and dried under vacuum for 6 hours to obtain an electrolyte matrix;

[0066] (3) Preparation of gel electrolyte: Prepare a special electrolyte solution for supercapacitors in an argon atmosphere, immerse the electrolyte ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com