Manufacturing method of high voltage polymer lithium ion capacitor and lithium ion capacitor

A manufacturing method and polymer technology, which are applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problem of difficult to meet the use requirements of long cycle life, reduce the risk of pulverization and shedding, and maintain stability. the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

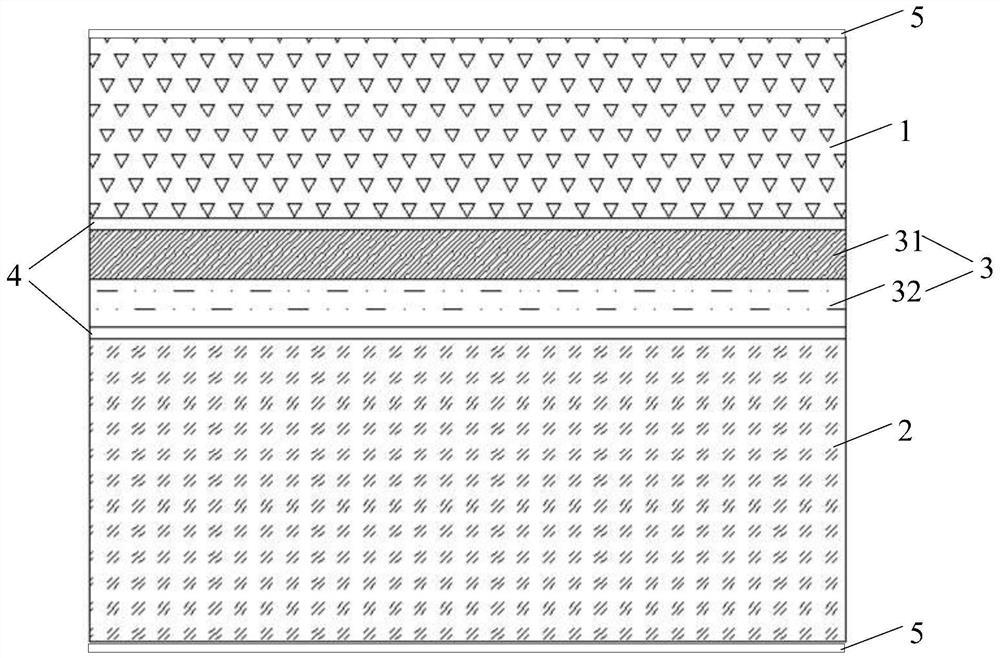

[0045] The preparation method of the mixed solution includes: adding methyl methacrylate into the electrolyte solution, stirring for 0.5h to 2h; adding polyvinylidene fluoride, triethylene glycol dimethacrylate and benzyl peroxide to the above solution Acyl or azobisisobutyronitrile was stirred for 2h to 3h, and the temperature was controlled below 20°C.

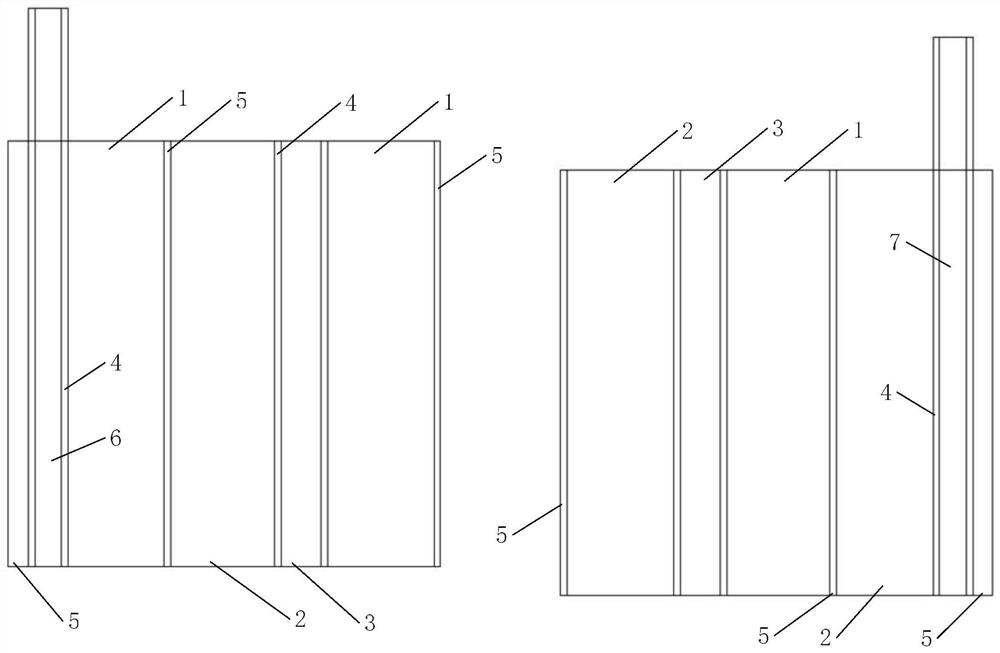

[0046] The bipolar pole piece, the unilateral positive pole piece and the unilateral negative pole piece that adsorb the mixed solution are heated and wound up to obtain the composite bipolar pole piece, the composite unilateral positive pole piece and the composite unilateral positive pole piece wrapped with the polymer film, respectively. The pole roll of the composite unilateral negative pole piece.

[0047] When the mixed solution is heated at 70°C to 90°C, the polymer monomer polymerization reaction will be initiated, so that the mixed solution adsorbed on the outside of the bipolar pole piece, the unilateral positive p...

Embodiment 1

[0053] An embodiment of the present invention provides a method for manufacturing a high-voltage polymer lithium-ion capacitor, comprising the following steps:

[0054] The NCM523 (LiNi 0.5 Co 0.2 Mn 0.3 O 2 ) Weigh the corresponding weight according to the ratio of 92.5% by weight and add it into the mixing barrel of the binder polytetrafluoroethylene solution with a formula weight ratio of 2.5%, stir for 1.5h, and add carbon fibers with a weight ratio of 1.5% and 1% graphite. The composite conductive agent of alkene and 2.5% carbon nanotubes is then stirred at high speed for 2.5 hours; it is transported to a buffer tank through a double-screw extrusion equipment for use, and the slurry of the positive electrode active material is obtained.

[0055] Activated carbon and lithium powder were weighed according to the weight ratio of 91.5%, and the corresponding weight was added to the mixing tank of the binder polytetrafluoroethylene solution with a formula weight ratio of 2%...

Embodiment 2

[0068] An embodiment of the present invention provides a method for manufacturing a high-voltage polymer lithium-ion capacitor, comprising the following steps:

[0069] The NCM523 (LiNi 0.5 Co 0.2 Mn 0.3 O 2 ) Weigh the corresponding weight according to the ratio of 92.5% by weight and add it into the mixing barrel of the binder polytetrafluoroethylene solution with a formula weight ratio of 2.5%, stir for 1.5h, and add carbon fibers with a weight ratio of 1.5% and 1% graphite. The composite conductive agent of alkene and 2.5% carbon nanotubes is then stirred at high speed for 2.5 hours; it is transported to a buffer tank through a double-screw extrusion equipment for use, and the slurry of the positive electrode active material is obtained.

[0070] Activated carbon and lithium powder were weighed according to the weight ratio of 91.5%, and the corresponding weight was added to the mixing tank of the binder polytetrafluoroethylene solution with a formula weight ratio of 2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com