Method for improving growth quality of silicon carbide epitaxial film

A technology of epitaxial thin film and silicon carbide, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of silicon carbide epitaxial thin film with many defects and the reduction of thin film defects, achieve good application prospects, reduce crystal defects, and can highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for improving the quality of silicon carbide epitaxial film growth, comprising the following steps:

[0046] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, perform standard cleaning and place the substrate on a small plate in the reaction chamber;

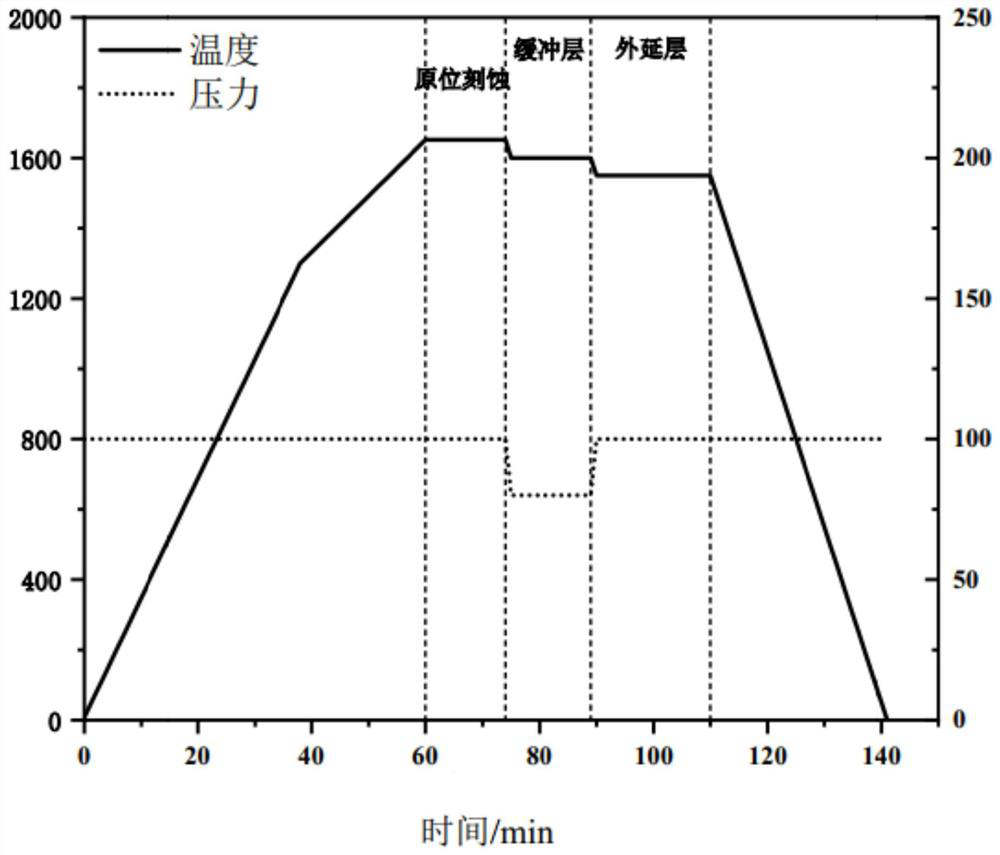

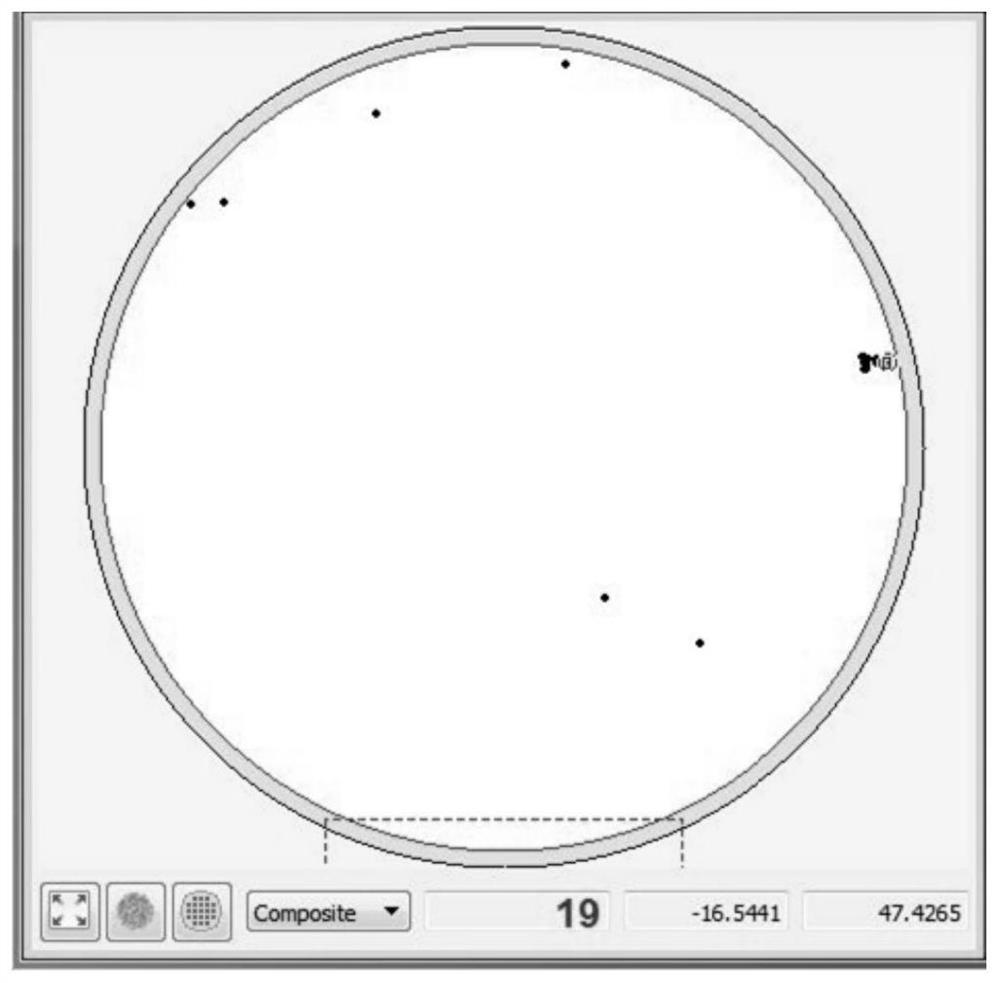

[0047] Step 2: Evacuate the reaction chamber to a vacuum, then inject hydrogen, keep the flow rate of hydrogen at 150L / min, and the pressure of the reaction chamber at 100mbar. Use radio frequency heating to heat the reaction chamber at a fixed rate of 34°C / min. The room temperature is raised to 1300°C; then the heating rate is reduced to 16°C / min, and the temperature is raised to 1625°C etching temperature. The small disk air flotation uses a certain proportion of hydrogen-argon mixed gas, the volume ratio of hydrogen and argon in the hydrogen-argon mixed gas 1:1, the air flotation flow rate of the small plate is 100sccm, and the constant temperature is etched for 15...

Embodiment 2

[0054] A method for improving the quality of silicon carbide epitaxial film growth, comprising the following steps:

[0055] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, perform standard cleaning and place the substrate on a small plate in the reaction chamber;

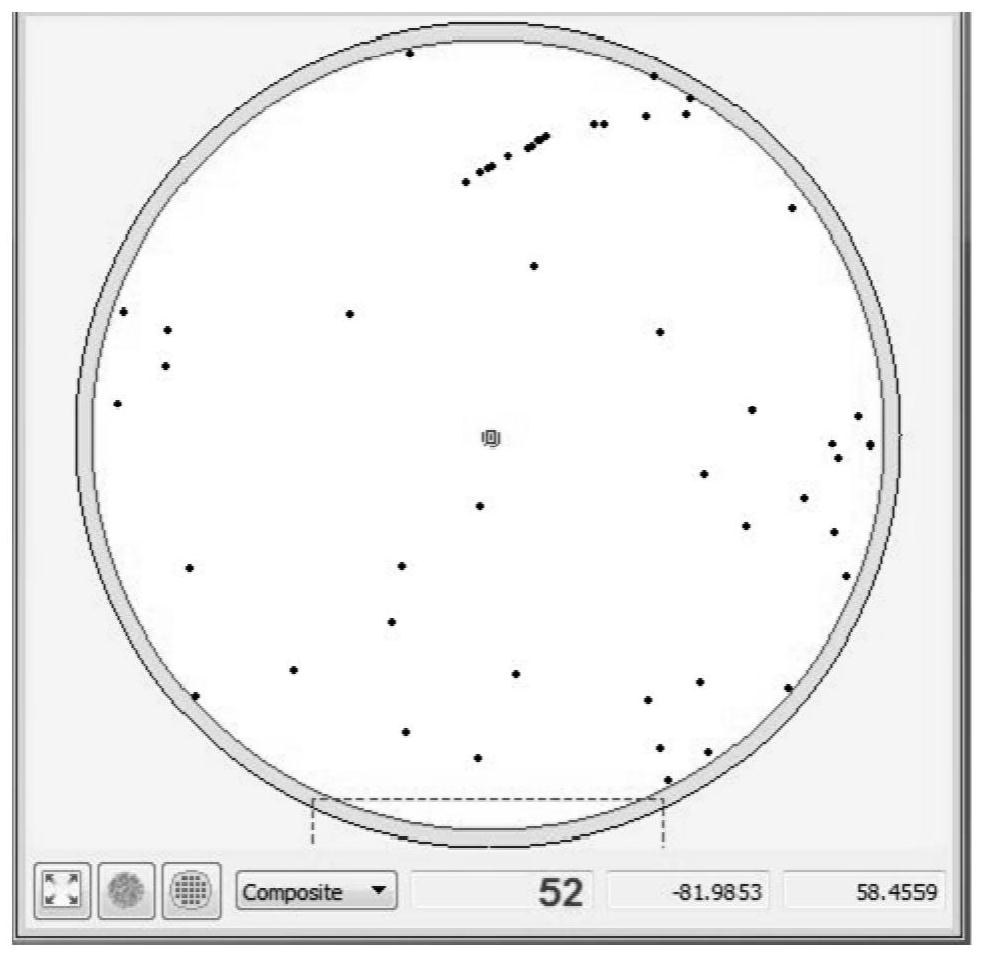

[0056] Step 2: Evacuate the reaction chamber to a vacuum, then inject hydrogen gas, keep the flow rate of hydrogen gas at 200L / min, and the pressure of the reaction chamber at 150mbar. Use radio frequency heating to heat the reaction chamber at a fixed rate of 30°C / min. The room temperature is raised to 1300°C; then the heating rate is reduced to 20°C / min, and the temperature is raised to 1675°C etching temperature. The small disk air flotation uses a certain proportion of hydrogen-argon mixed gas, the volume ratio of hydrogen and argon in the hydrogen-argon mixed gas The ratio is 3:7, the air flotation flow rate of the small plate is 600sccm, and the constant tempera...

Embodiment 3

[0062] A method for improving the quality of silicon carbide epitaxial film growth, comprising the following steps:

[0063] Step 1: Select a silicon carbide substrate with a silicon surface that is 4° to the direction, perform standard cleaning and place the substrate on a small plate in the reaction chamber;

[0064] Step 2: Evacuate the reaction chamber to a vacuum, then inject hydrogen, keep the flow rate of hydrogen at 180L / min, and the pressure of the reaction chamber at 120mbar, use radio frequency heating, with a fixed heating rate of 40°C / min, the reaction chamber is heated by The room temperature is raised to 1350°C; then the heating rate is reduced to 20°C / min, and the temperature is raised to 1655°C etching temperature. The small disk air flotation uses a certain proportion of hydrogen-argon mixed gas, the volume ratio of hydrogen and argon in the hydrogen-argon mixed gas 3:7, the air flotation flow rate of the small plate is 500sccm, and the etching is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com