Preparation method and application method of graphene oxide/carbon nanotube asymmetric separation membrane

A technology of carbon nanotubes and application methods, which is applied in the field of membrane separation water treatment, can solve the problems of membrane water permeability limitation, reduction of graphene oxide oxygen-containing functional groups, reduction of interception performance, etc., to achieve enhanced ion interception performance and enhanced ion partitioning effect , The effect of ion retention improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

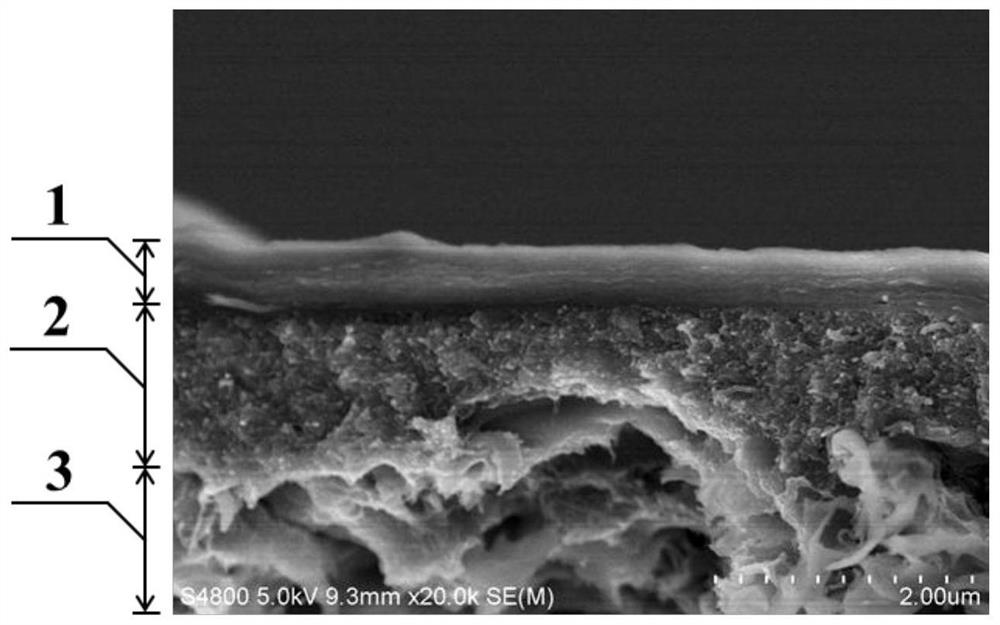

[0040] The invention provides a preparation method of a graphene oxide / carbon nanotube asymmetric separation membrane, which is specifically implemented according to the following steps:

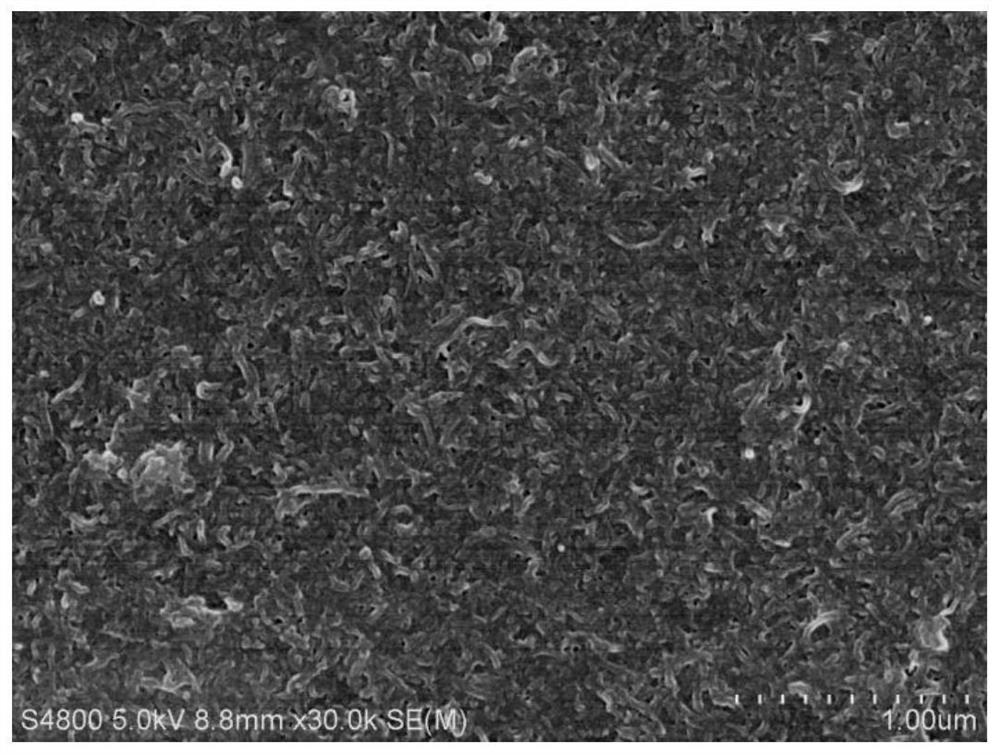

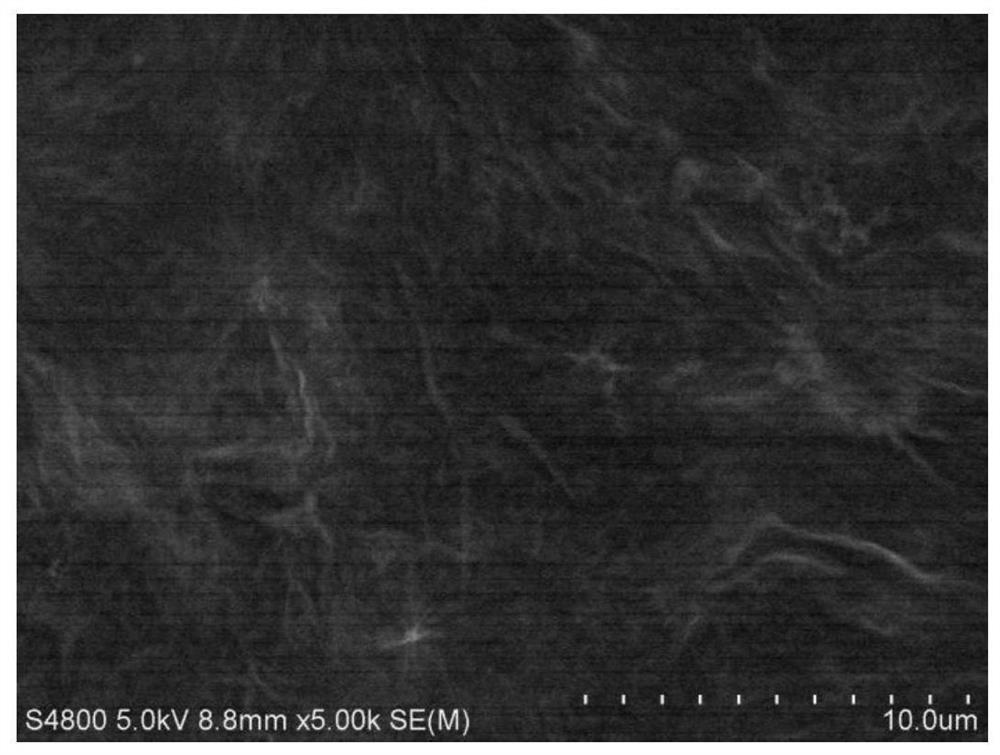

[0041] (1) Use a mixed acid solution of 70wt.% concentrated nitric acid and concentrated sulfuric acid with v / v of 1:3 to acidify carbon nanotubes with an outer diameter of 10-20 nm, and oxidize at 80°C for 1 h to obtain acidified carbon nanotubes Tube. The acidified carbon nanotubes were then placed in high-purity water, dispersed uniformly by ultrasonic, and prepared to a concentration of 0.2 mg mL. -1 of carbon nanotube dispersions. Subsequently, 40 mL of the carbon nanotube dispersion liquid was suction filtered onto the polyvinylidene fluoride microfiltration membrane substrate through a vacuum filtration device, and dried at 60 °C for 2 h to form a carbon nanotube layer;

[0042] (2) Using 8000 mesh graphite powder to prepare graphene oxide by Hummers method, and uniformly dispersing...

Embodiment 2

[0048] The invention provides a preparation method of a graphene oxide / carbon nanotube asymmetric separation membrane, which is specifically implemented according to the following steps:

[0049] (1) Use a mixed acid solution of 70wt.% concentrated nitric acid and concentrated sulfuric acid with a v / v of 1:3 to acidify carbon nanotubes with an outer diameter of 8-15nm, and oxidize at 60°C for 2h to obtain acidified carbon nanotubes Tube. The acidified carbon nanotubes were then placed in high-purity water, dispersed uniformly by ultrasonic, and prepared to a concentration of 0.2 mg mL. -1 of carbon nanotube dispersions. Subsequently, 50 mL of the carbon nanotube dispersion liquid was suction filtered onto the polyethersulfone ultrafiltration membrane substrate through a vacuum filtration device, and dried at 80 °C for 2 h to form a carbon nanotube layer;

[0050] (2) Using 2000 mesh graphite powder to prepare graphene oxide by Hummers method, and uniformly dispersing graphen...

Embodiment 3

[0056] The invention provides a preparation method of a graphene oxide / carbon nanotube asymmetric separation membrane, which is specifically implemented according to the following steps:

[0057] (1) Using a mixed acid solution of 70wt.% concentrated nitric acid and concentrated sulfuric acid with a v / v of 1:3 to acidify carbon nanotubes with an outer diameter of 20-40nm, and oxidize at 100°C for 0.5h to obtain acidified carbon nanotube. The acidified carbon nanotubes were then placed in high-purity water, dispersed uniformly by ultrasonic, and prepared to a concentration of 0.2 mg mL. -1 of carbon nanotube dispersions. Subsequently, 60 mL of the carbon nanotube dispersion liquid was suction filtered onto the cellulose acetate microfiltration membrane substrate through a vacuum filtration device, and dried at 80 °C for 2 h to form a carbon nanotube layer;

[0058] (2) Using 325 mesh graphite powder to prepare graphene oxide by Hummers method, and uniformly dispersing graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com