Method for preparing stannous chloride crystals by utilizing PCB tin stripping waste liquid

A technology of stannous chloride and tin tetrachloride, applied in the directions such as stannous chloride, tin halide, photography technology, etc., achieves the effects of low production cost, low environmental pollution, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

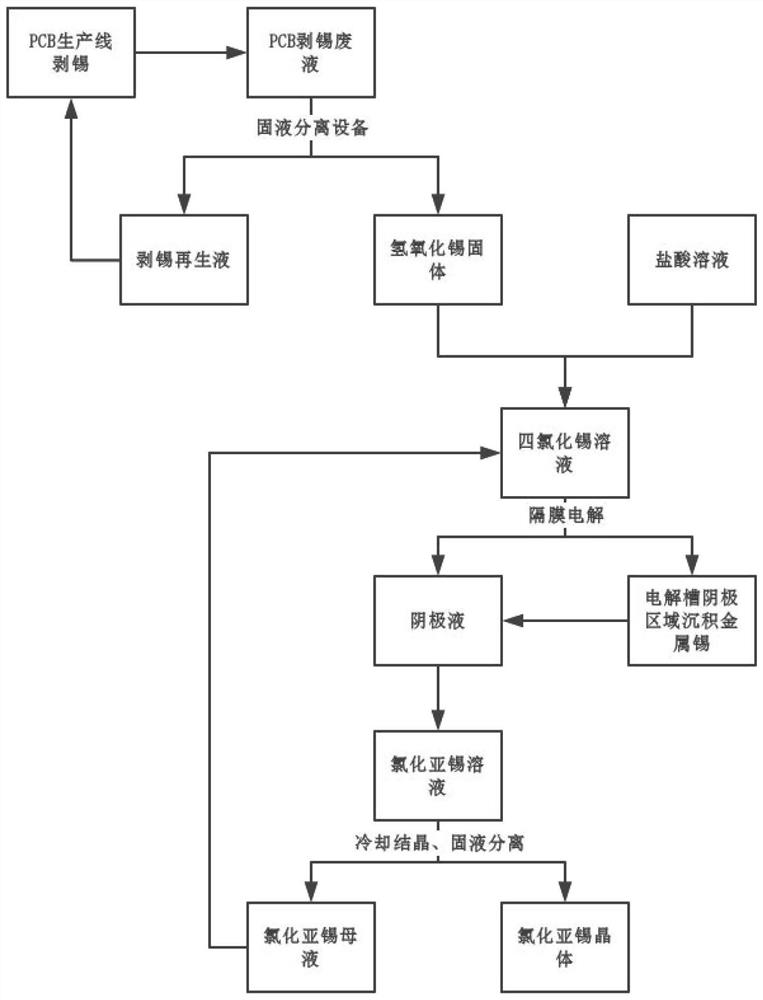

Image

Examples

Embodiment 1

[0043] Configure a tin stripping solution with a methanesulfonic acid concentration of 5mol / L and a hydrogen peroxide concentration of 50ml / L, put it into the circuit board tin stripping tank, control the tin stripping temperature at 40°C, and add hydrogen peroxide quantitatively during the tin stripping process to maintain its concentration At 50ml / L, replace the tin stripping solution after the tin hydroxide content in the tin stripping solution reaches a certain concentration.

[0044] A kind of method utilizing PCB tin stripping waste liquid to prepare stannous chloride crystal comprises the following steps:

[0045] Step 1: Collect the PCB tin stripping waste liquid, use a filter press to separate the solid and liquid in the PCB tin stripping waste liquid, and collect the solids of the PCB tin stripping waste liquid, and the solid is tin hydroxide solid;

[0046] Step 2: Clean the tin hydroxide solid prepared in step 1, add hydrochloric acid solution to the cleaned tin hy...

Embodiment 2

[0057] Configure a tin stripping solution with a methanesulfonic acid concentration of 5.5mol / L and a hydrogen peroxide concentration of 60ml / L, put it into the circuit board tin stripping cylinder, control the stripping temperature at 45°C, and add hydrogen peroxide quantitatively during the tin stripping process to make its concentration Keep it at 60ml / L, and replace the tin stripping solution after the tin hydroxide content of the tin stripping solution reaches a certain concentration.

[0058] A kind of method utilizing PCB tin stripping waste liquid to prepare stannous chloride crystal comprises the following steps:

[0059] Step 1: Collect the PCB tin stripping waste liquid, use a filter press to separate the solid and liquid in the PCB tin stripping waste liquid, and collect the solids of the PCB tin stripping waste liquid, and the solid is tin hydroxide solid;

[0060] Step 2: Clean the tin hydroxide solid prepared in step 1, add hydrochloric acid solution to the clea...

Embodiment 3

[0071] Configure a tin stripping solution with a methanesulfonic acid concentration of 6mol / L and a hydrogen peroxide concentration of 70ml / L, put it into the circuit board tin stripping tank, control the tin stripping temperature at 50°C, and add hydrogen peroxide quantitatively during the tin stripping process to maintain its concentration At 70ml / L, replace the tin stripping solution after the tin hydroxide content in the tin stripping solution reaches a certain concentration.

[0072] A kind of method utilizing PCB tin stripping waste liquid to prepare stannous chloride crystal comprises the following steps:

[0073] Step 1: Collecting the PCB tin stripping waste liquid, using a centrifuge to separate the solid and liquid in the PCB tin stripping waste liquid, and collecting the solids of the PCB tin stripping waste liquid, the solid being tin hydroxide solid;

[0074] Step 2: Clean the tin hydroxide solid prepared in step 1, add hydrochloric acid solution to the cleaned t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com