Patents

Literature

146 results about "Tin(IV) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin(IV) chloride, also known as tin tetrachloride or stannic chloride, is an inorganic compound with the formula SnCl₄. It is a colorless hygroscopic liquid, which fumes on contact with air. It is used as a precursor to other tin compounds. It was first discovered by Andreas Libavius (1550–1616) and was known as spiritus fumans libavii.

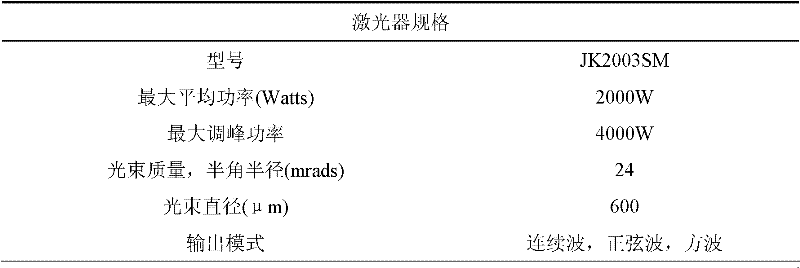

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

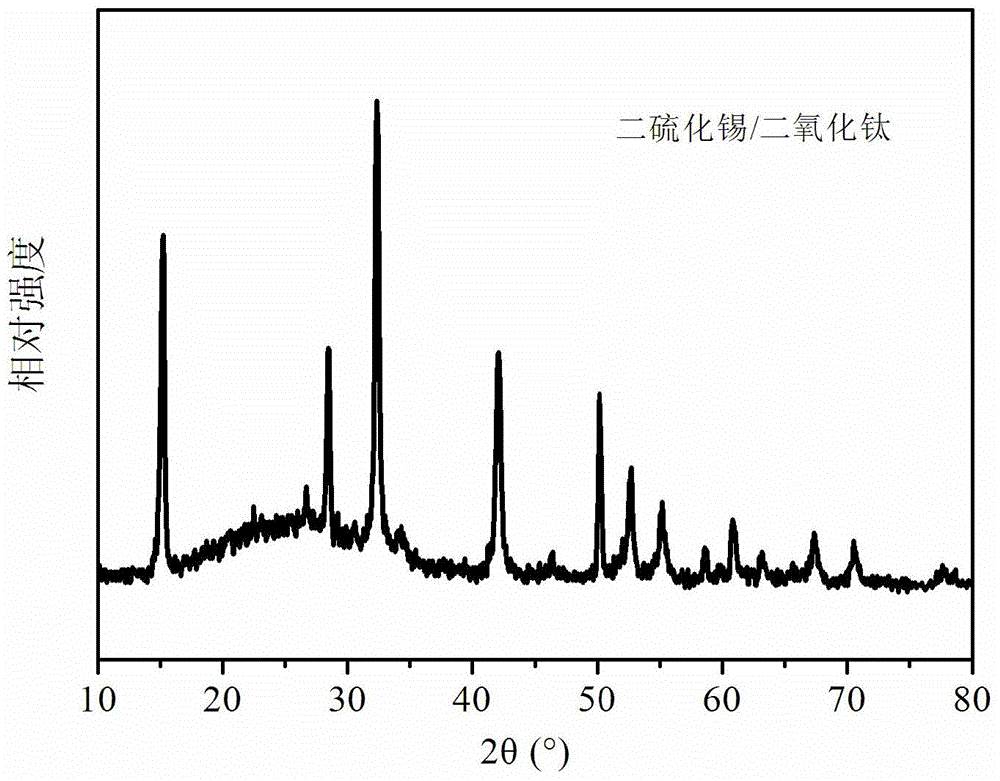

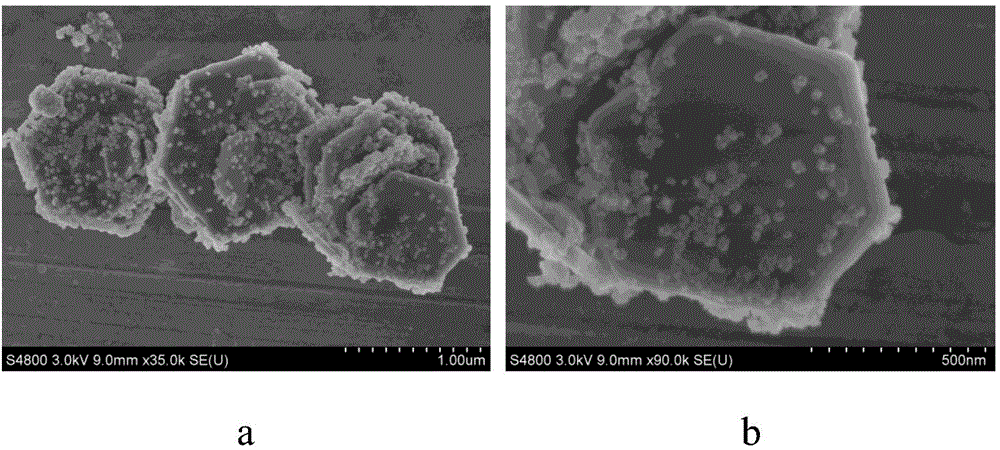

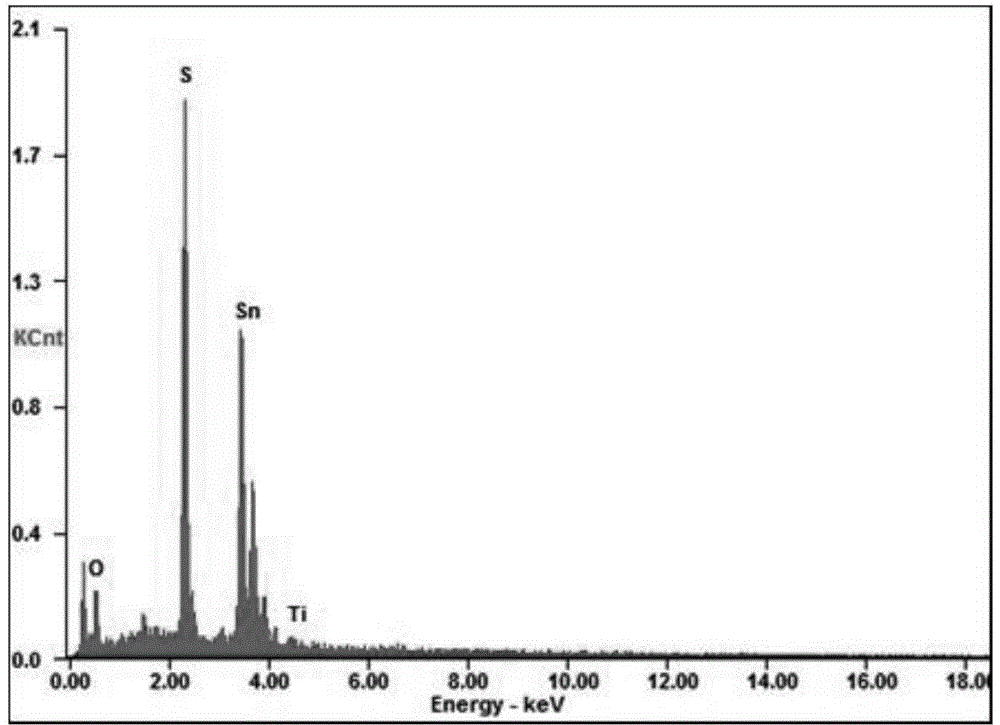

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

ActiveCN104888753AUniform sizeRegular shapeMaterial nanotechnologyWater/sewage treatment by irradiationThioureaPotassium dichromate

The invention discloses a tin disulfide / titanium dioxide compound photocatalyst which is prepared from a precursor solution through hydrothermal reaction, wherein the precursor solution is prepared from tin disulfide powder and butyl titanate in the mass ratio of 1:(20-100). The compound photocatalyst has controllable size, tin disulfide is of a hexagonal nanoscale flake shape, titanium dioxide nano-particles are uniformly loaded on tin disulfide, and the photocatalyst material has high photocatalytic reduction efficiency on potassium dichromate in a water body. The invention also discloses a preparation method of the compound photocatalyst. The preparation method comprises the following steps: a. preparing tin disulfide powder from tin chloride pentahydrate and thiourea; b. mixing the tin disulfide powder and butyl titanate to prepare the precursor solution; and c. hydrothermally heating the prepared precursor solution to prepare the compound photocatalyst. The preparation steps are simplified greatly, the control difficulty of technological parameters is lowered, and the large-scale preparation of the tin disulfide / titanium dioxide compound photocatalyst is realized.

Owner:澄城县海泰电子材料有限责任公司

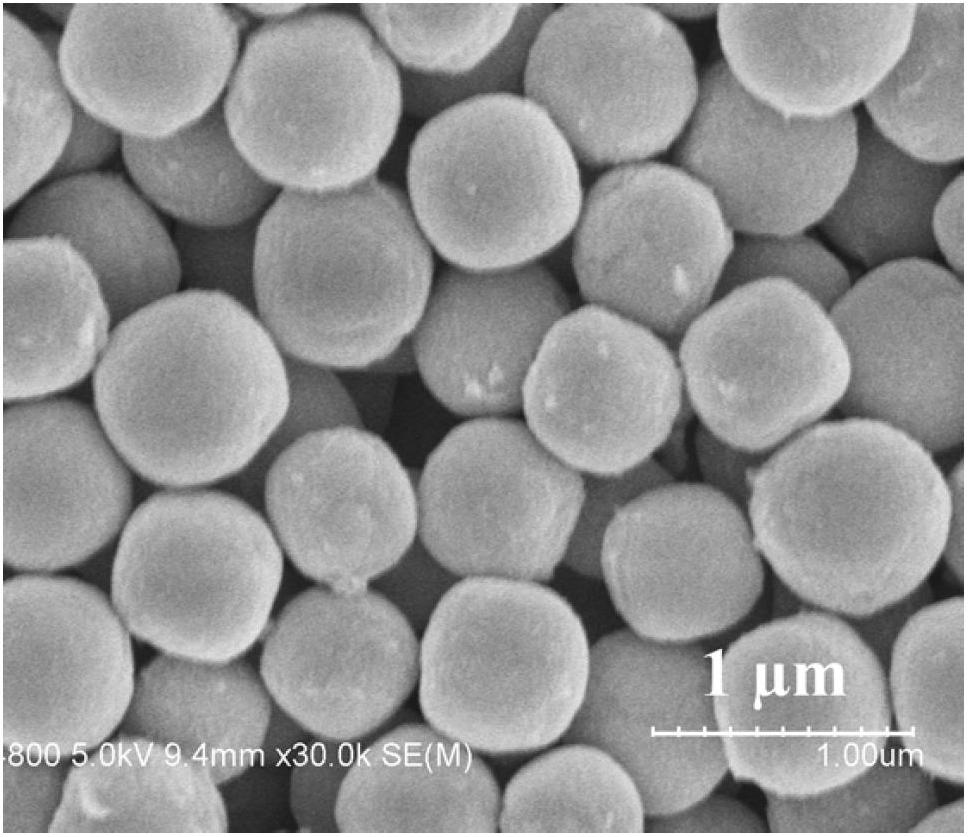

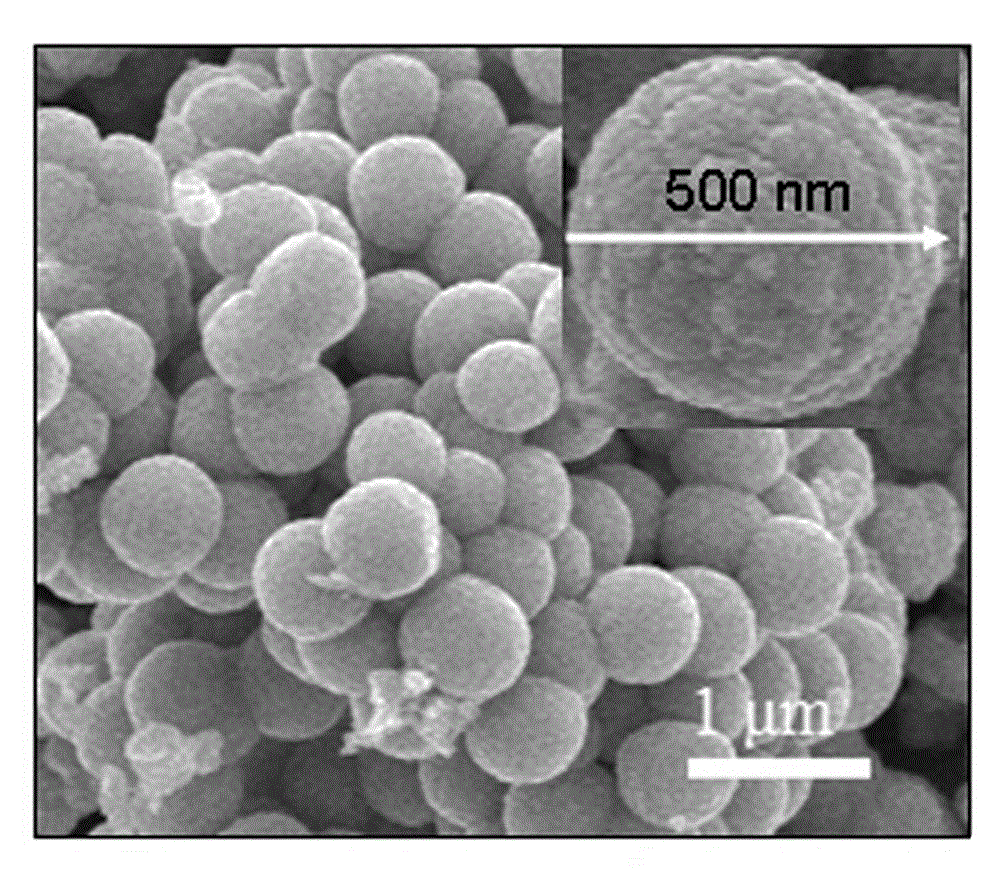

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

Metallic ion doped nano TiO2 transparent photo-catalytic emulsion and preparation method thereof

InactiveCN101062476AAchieve purificationAchieve degradationPhysical/chemical process catalystsSpectral responseAmmonium metavanadate

The metal ion mixed with TiO2 transparent optical catalyst lotion features in 0. 5-10% TiO2, mixed with V, Tin, Zn, Fe, OP emulsifier 1-10% with the rest being water, comprising a making of titanic chloride water solution, hydrolysis to generate TiO2+, VO3+, Sn4+, Zn2+, Fe3+ or Ce3+ compound oxidation deposit, low temperature complexing, hydrolysis to get the metal mixed nanometer TiO2 transparent catalyst lotion. It uses cheap titanium tetrachloride and ammonium vanadate, white copperas, Fe2cl3,tin tetrachloride as the inorganic material, using low temperature complex hydrolysis to allow higher ability to mix, expanding spectral response zone. Its maximum advantage is the direct use of sun light or fluorescent lamp, realizing complete degradation of organic pollutants, improving the speed and efficiency of photochemical catalysis and degradation for environmental purification.

Owner:HEBEI UNIVERSITY

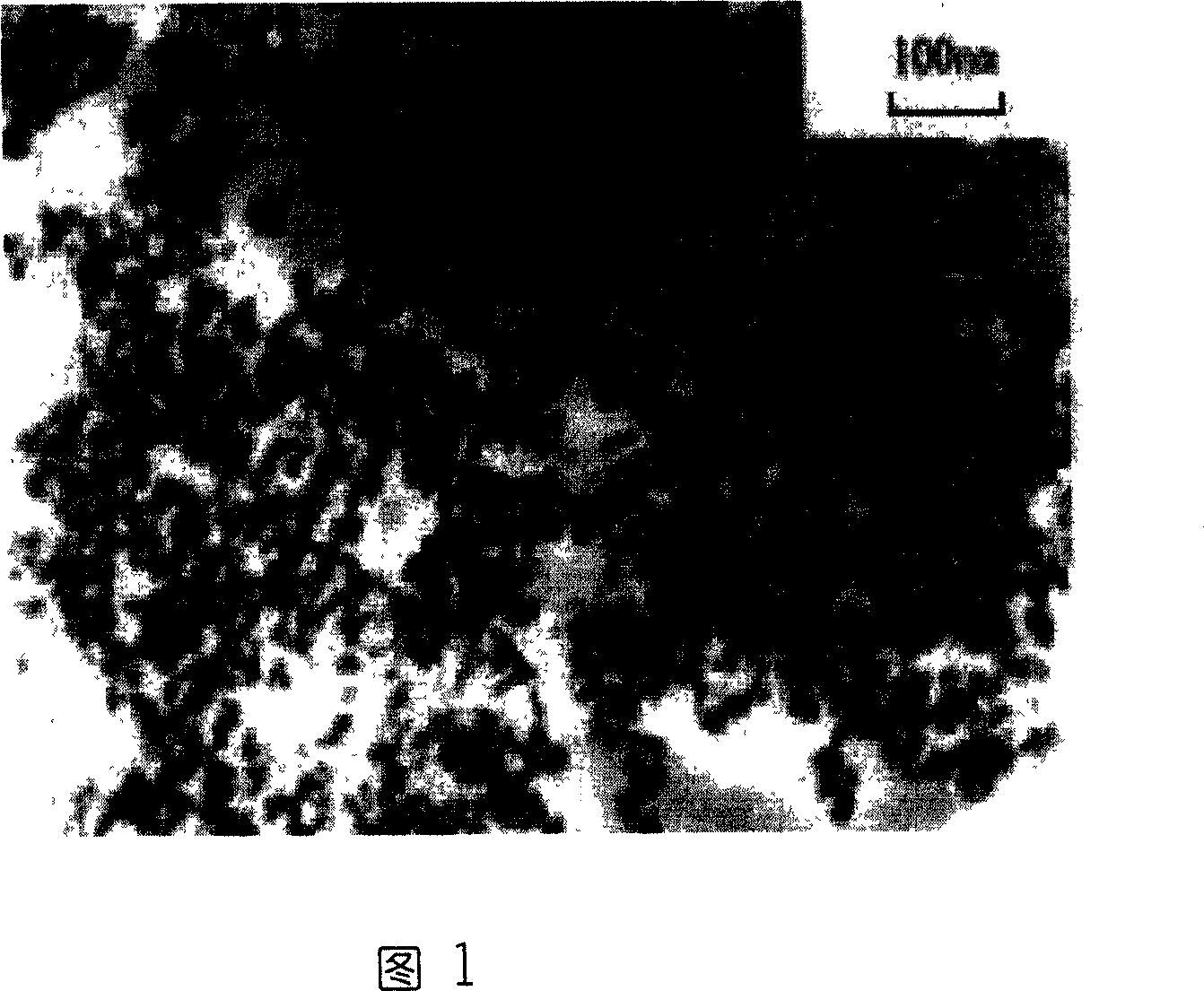

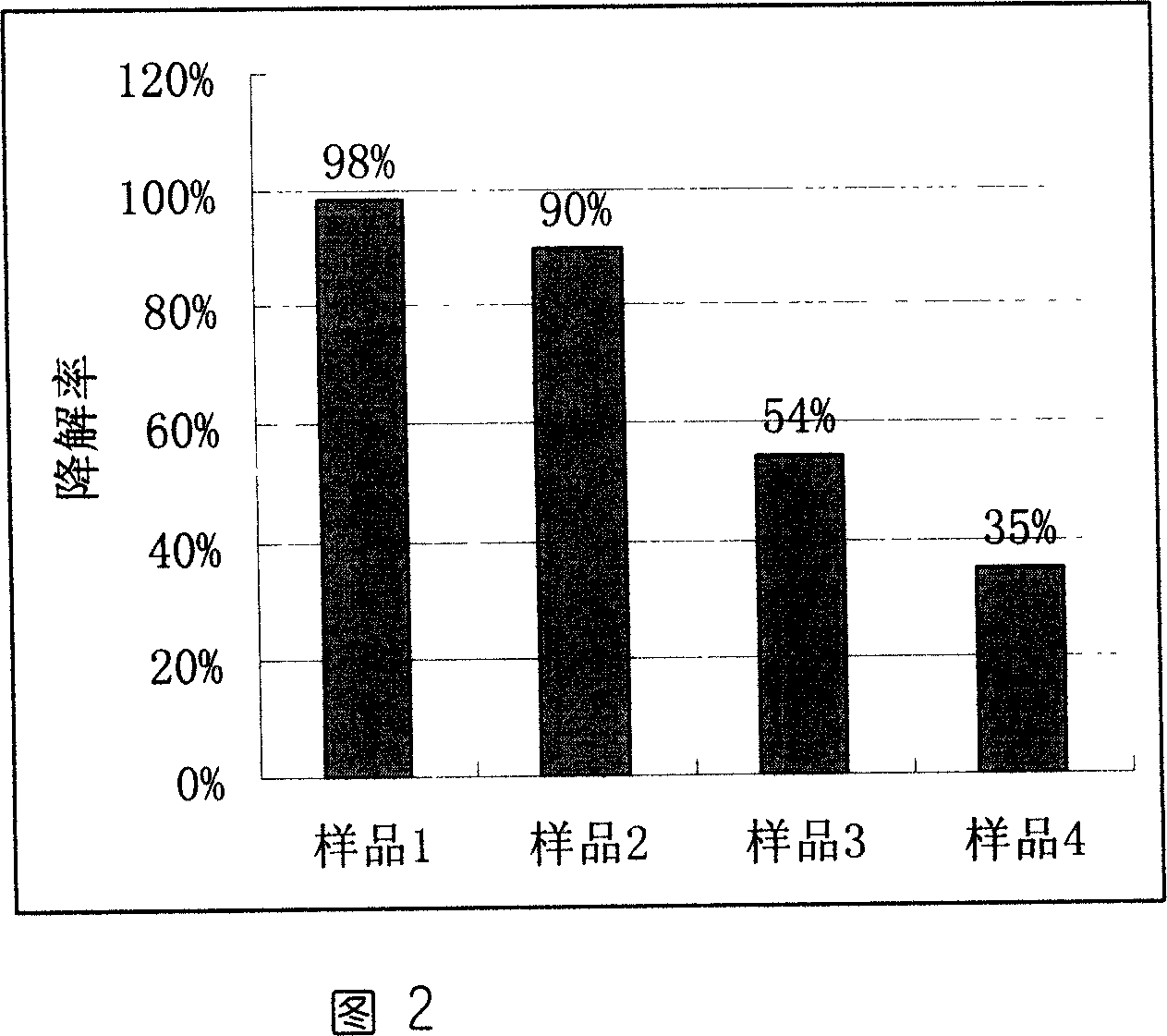

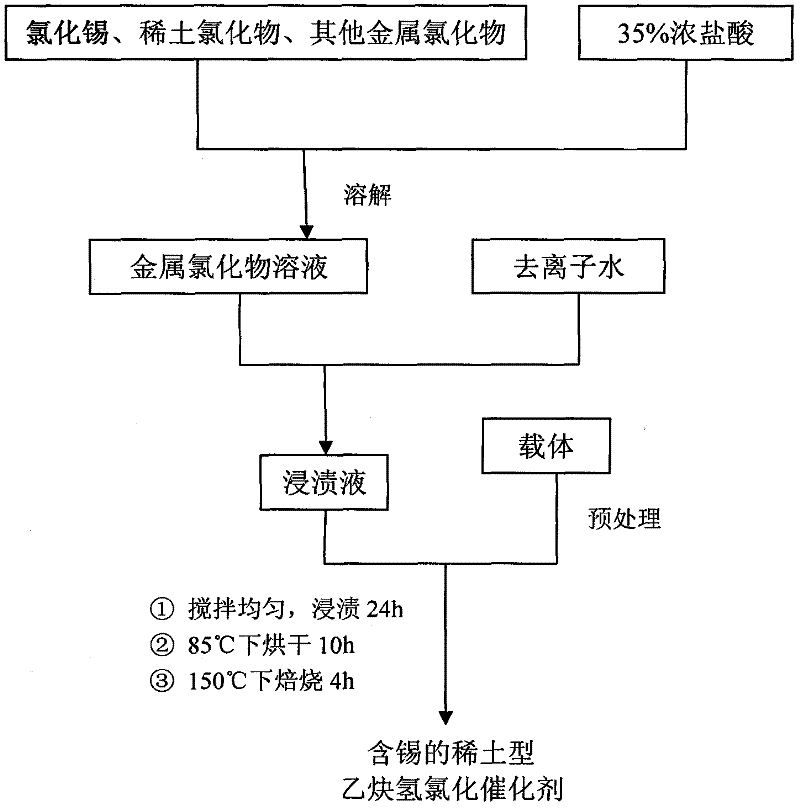

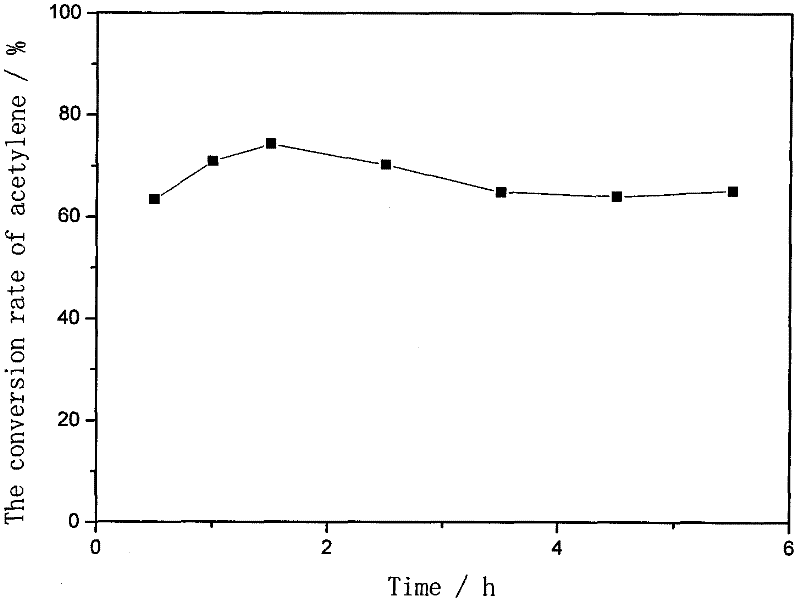

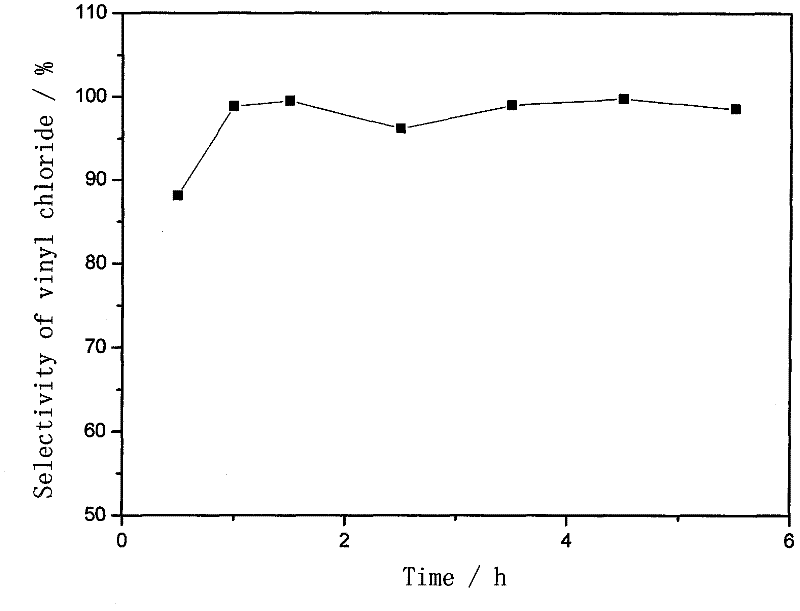

Method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin

InactiveCN102430418AHigh catalytic activitySimple processPhysical/chemical process catalystsPreparation by halogen halide additionMetal chlorideFixed bed

The invention disclose a method for preparing rare earth type hydrochlorination catalyst of acetylene comprising tin, which belongs to the field of preparing the hydrochlorination catalyst of acetylene. The catalyst comprises stannic chloride, rare earth chloride, other metal chlorides and carriers, wherein the rare earth chloride is adopted as cerium chloride or lanthanum chloride, and the carriers are cerium-zirconium powder or zirconia. The catalyst is prepared by soaking method, can be applied to fixed-bed reactors, has low cost, has no pollution, and has good catalytic activity and high selection in the process of producing vinyl chloride by hydrochlorination of acetylene.

Owner:INNER MONGOLIA UNIVERSITY

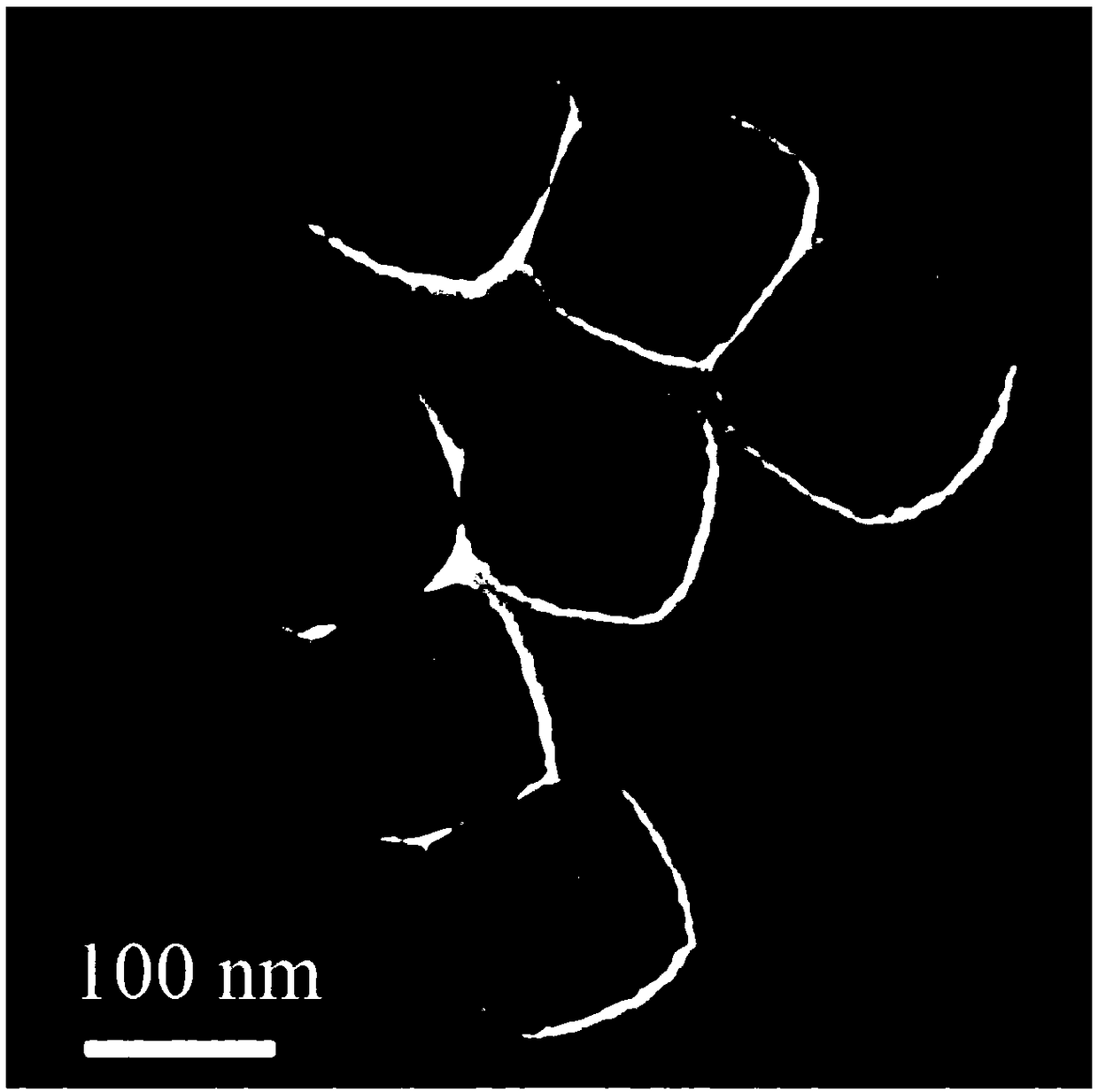

Preparation method of tin-dioxide-supported carbon nanorod material

ActiveCN106711409AVolume change controllableGood conductivity and stabilityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention discloses a preparation method of a tin-dioxide-supported carbon nanorod material. The method comprises the following steps: by using a cellulose raw material as the substrate, treating cellulose by an acid catalysis process to remove amorphous regions and impurity components in the cellulose, extracting a cellulose nanocrystal suspension, carrying out chemical supporting on the cellulose nanocrystals by using tin chloride to prepare tin-containing cellulose nanocrystals, and carrying out high-temperature oxidation-carbonization treatment to prepare the high-length-diameter-ratio tin-dioxide-supported carbon nanorod material of which the diameter is 10-30nm and the length is 150-350nm. By effectively utilizing the biomass material cellulose, the method has the characteristics of wide raw material sources, renewable raw material and no pollution. The carbon nanorods have the advantage of excellent electric conductivity and have the size which is not possessed by the past carbon material, and have favorable effects of relieving the volume change and improving the cycle performance of batteries.

Owner:ZHEJIANG SCI-TECH UNIV

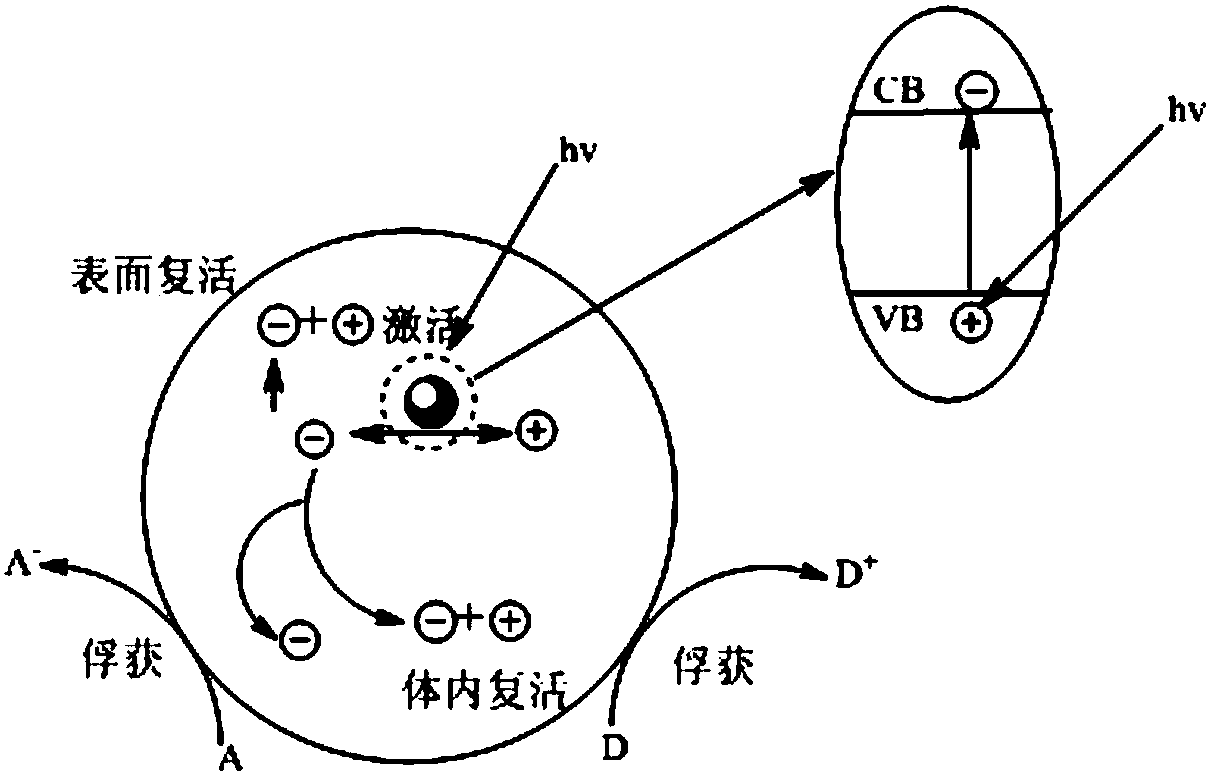

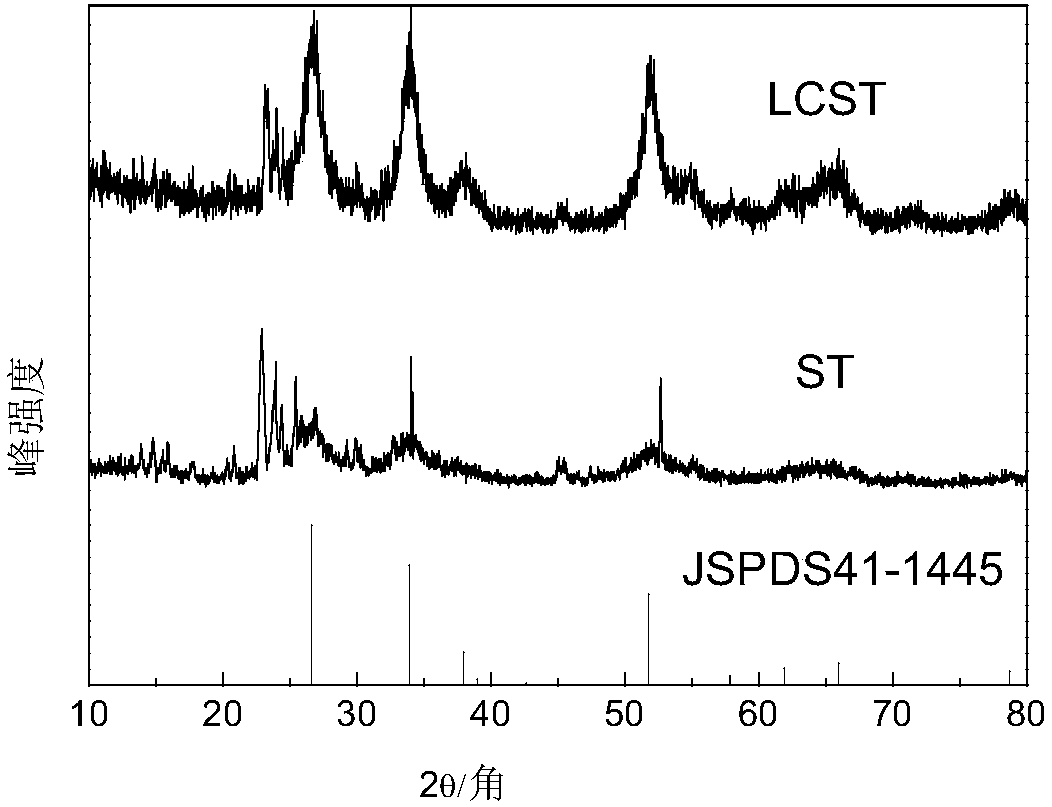

Synthetic method and application of rare-earth-doped SnO2/TS-1 nano photocatalytic material

PendingCN108452847AImprove photocatalytic performancePromote degradationMolecular sieve catalystsWater/sewage treatment by irradiationMolecular sieveCerium

The invention discloses a synthetic method and application of a rare-earth-doped SnO2 / TS-1 nano photocatalytic material. The tin chloride pentahydrate and a titanium-silicon molecular sieve are used as main raw materials, lanthanum or / and cerium is used as a rare-earth doping element, and a sol-gel method is used for synthesizing the rare-earth-doped SnO2 / TS-1 nano photocatalytic material. The synthetic method disclosed by the invention is simple, easy in operation and good in repeatability; after the rare-earth doping, the photocatalytic performance of the photocatalytic material can be significantly improved; particularly after the co-doping of La and Ce, the photocatalytic performance is obviously improved, and the degradation rate of the pohtocatalyst LCST for rhodamine B in rhodamineB simulation waste water can reach 99.87 percent; and the degradation effect for the actual printing dye is good, the degradation effect of LCST for acidic blue, active black, RGFL yellow, acidic redA-2BF in the actual dye waste water can separately reach 99.85 percent, 99.78 percent, 96.15 percent and 94.6 percent, and the reusability is good.

Owner:HUNAN INSTITUTE OF ENGINEERING

Preparation method for improving grain size and density of CZTS film

InactiveCN103400903APrevent volatilizationAvoid pollutionTin compoundsFinal product manufactureNew energyThiourea

The invention provides a preparation method for a CZTS film which has a square structure, high density and large granules, and belongs to the field of semiconductor photoelectric material and new energy material. The preparation method is characterized by adopting four compounds as raw materials, including copper acetate (Cu(CH3OO)2.H2O), zinc acetate (Zn(CH3COO)2), tin chloride (SnCl2) and sulfourea (CN2H4S); after the CZTS film is prepared by adopting a spin coating method, a CZTS film material with high density and good crystallization quality is prepared via high-temperature sulfurization process performed in a sealed quartz tube. The preparation method has the advantages of simple preparation process, short reaction time, controllable component and structure, low cost, no pollution caused during production and the like, can be applicable to production of mass CZTS film photovoltaic cell absorption material.

Owner:JILIN UNIV

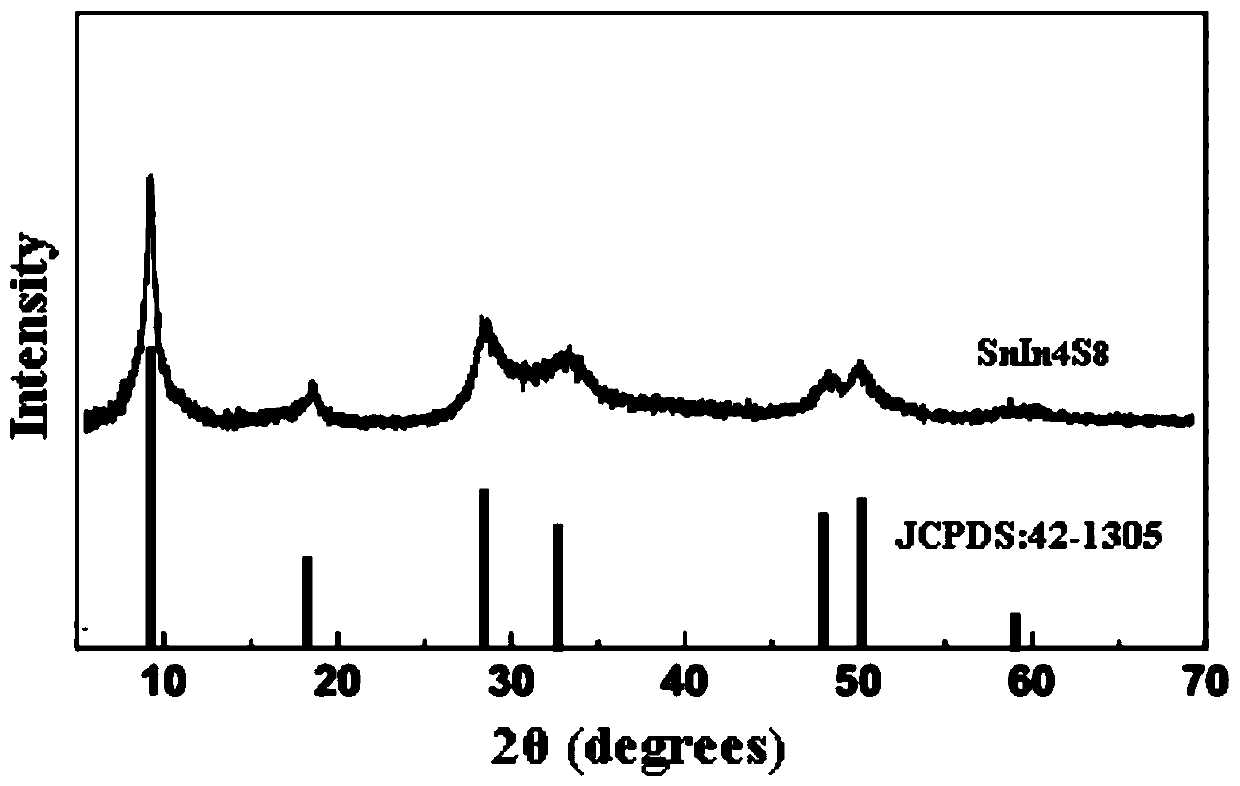

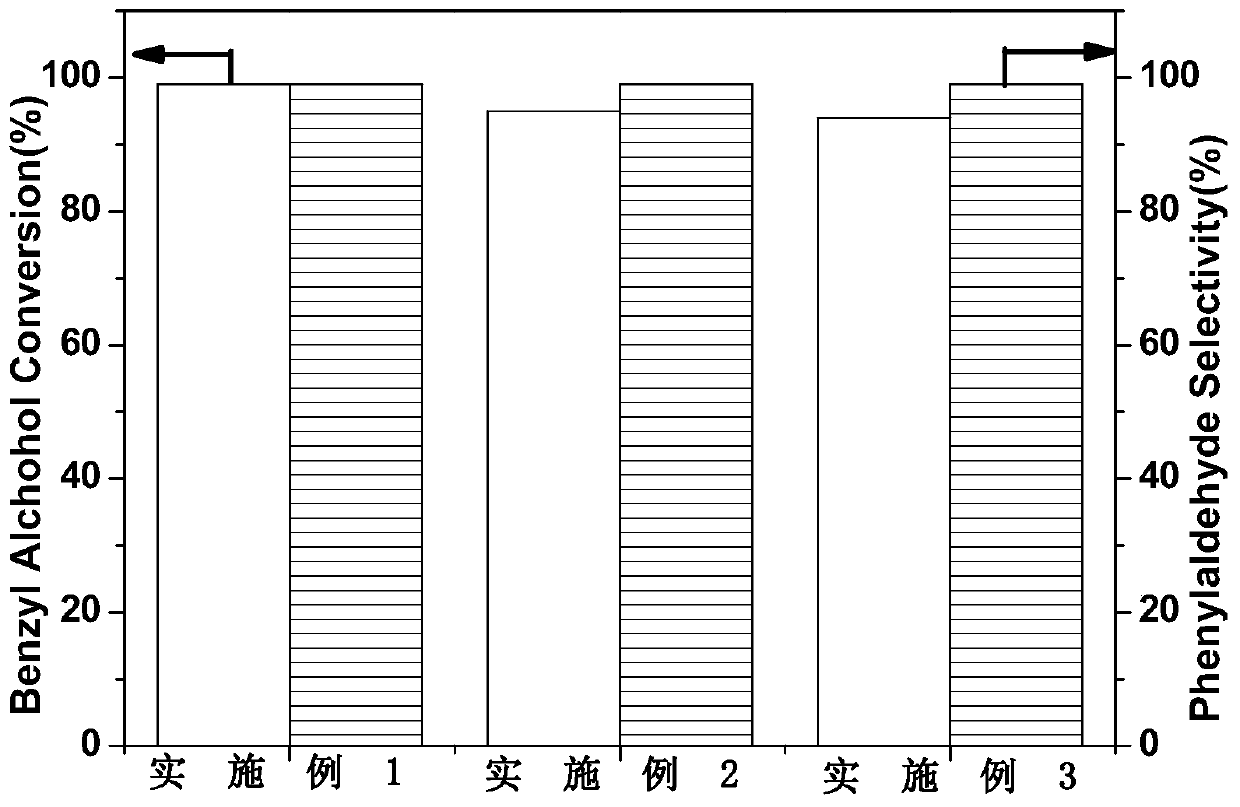

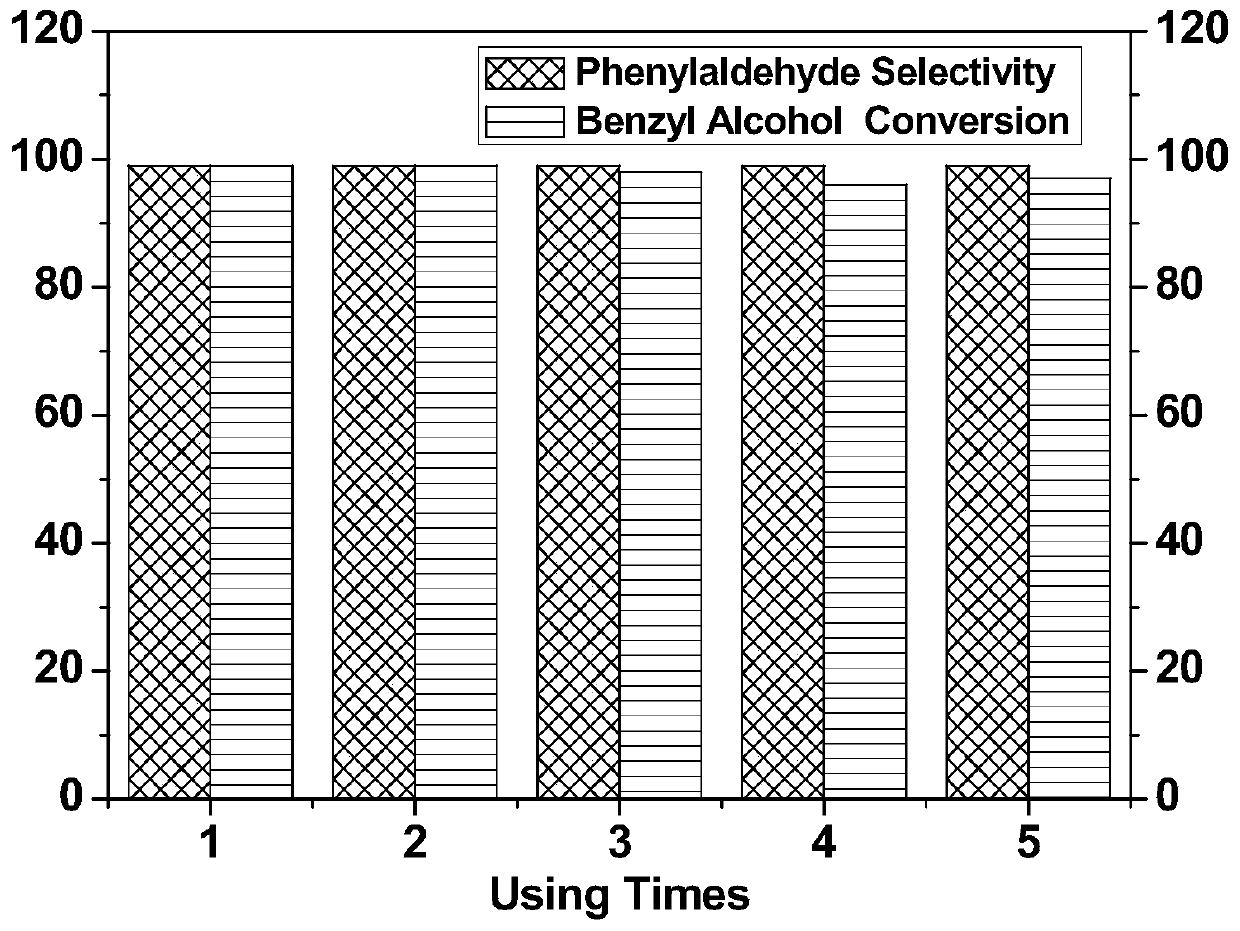

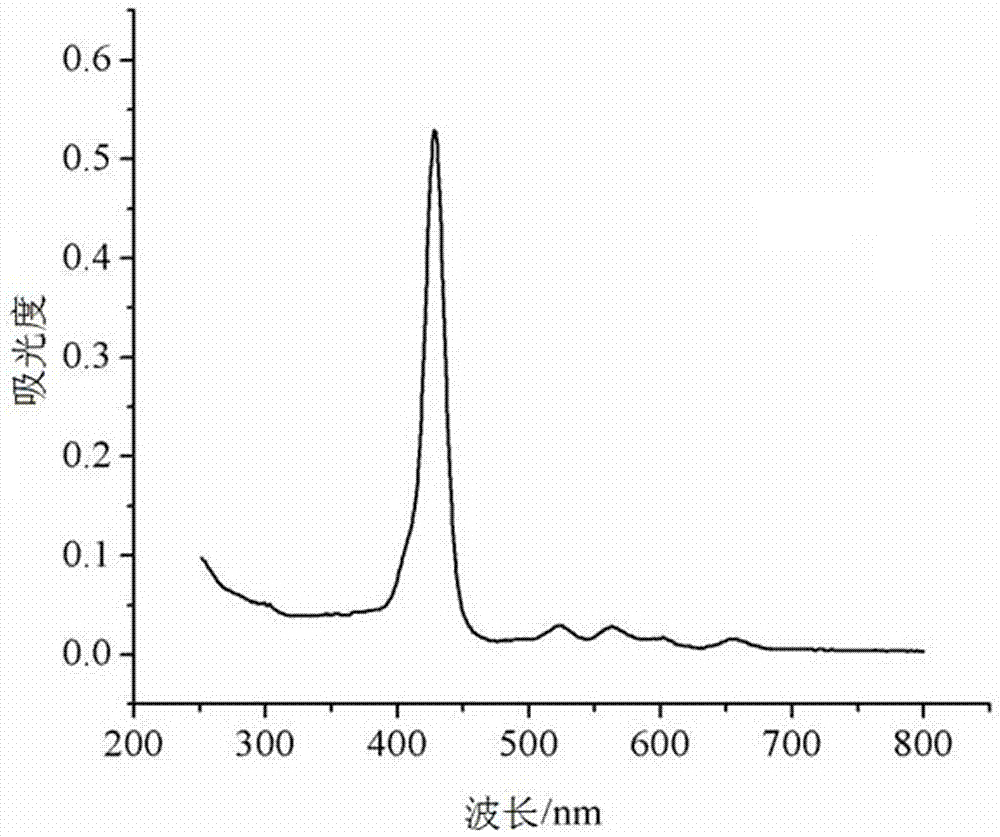

Preparation method of indium tin sulfide visible-light-induced photocatalyst and visible-light-induced catalytic performance application of indium tin sulfide visible-light-induced photocatalyst

PendingCN111250109ASimple processImprove stabilityTin compoundsPhysical/chemical process catalystsIndium TrichlorideThiourea

The invention relates to the technical field of material preparation and photocatalysis. The technical scheme comprises that a preparation method of an indium tin sulfide visible-light-induced photocatalyst comprises the following steps: (1) weighing stannic chloride pentahydrate and indium trichloride, dissolving stannic chloride pentahydrate and indium trichloride in a proper amount of deionizedwater, then weighing any one reactant of three sulfur sources, namely thioacetamide, thiourea or L-cysteine, adding the reactant into the uniformly stirred aqueous solution, adjusting the pH value to1-13, and continuously stirring for 2 h, wherein the molar ratio of tin tetrachloride pentahydrate to indium trichloride to the reactant is 1.5:4:8; (2) transferring the uniformly stirred solution into a hydrothermal reaction kettle, and carrying out a reaction for 10-12 h in an oven at the temperature of 140-180 DEG C; and naturally cooling to room temperature to obtain precipitates, respectively washing the precipitates with deionized water and absolute ethyl alcohol for multiple times, and carrying out vacuum drying at the temperature of 60 DEG C for 10 h to obtain an orange powder sample.The preparation method is simple in steps and low in cost.

Owner:ZHEJIANG SHUREN UNIV

Method for measuring total iron content in fly ash

InactiveCN103472059AReduce concentrationImprove solubilityMaterial analysis by observing effect on chemical indicatorWater chlorinationPotassium dichromate

The invention provides a method for measuring total iron content in fly ash. The method comprises the steps that 1) a sample to be measured is weighed, concentrated hydrochloric acid, a sodium fluoride solution and a stannous chloride solution are added into the sample to be measured and are heated to dissolve the sample; 2) the stannous chloride solution is continuously dripped into the sample in the sample dissolving process until the test solution is faint yellow or colorless; 3) after the sample is dissolved completely, solid potassium permanganate is added into the sample, and the solution is boiled until the solution is reddish; 4) the stannous chloride solution is dripped into the test solution again to enable the test solution to return to be faint yellow, the volume of the solution is concentrated to be about 20mL, then 100mL of water is added into the solution, and the solution is cooled down; 5) sodium tungstate is used as an indicator, a titanium trichloride solution is dripped into the test solution to enable the test solution to return to be light blue, titration is immediately conducted by a potassium dichromate standard titration solution after the test solution is faded to be colorless from light blue, and the total iron content is computed according to the volume of wasted potassium dichromate standard titration solution. The method for measuring the total iron content in the fly ash eliminates interference of reducibility ions in the test solution, and improves accuracy.

Owner:武汉钢铁有限公司

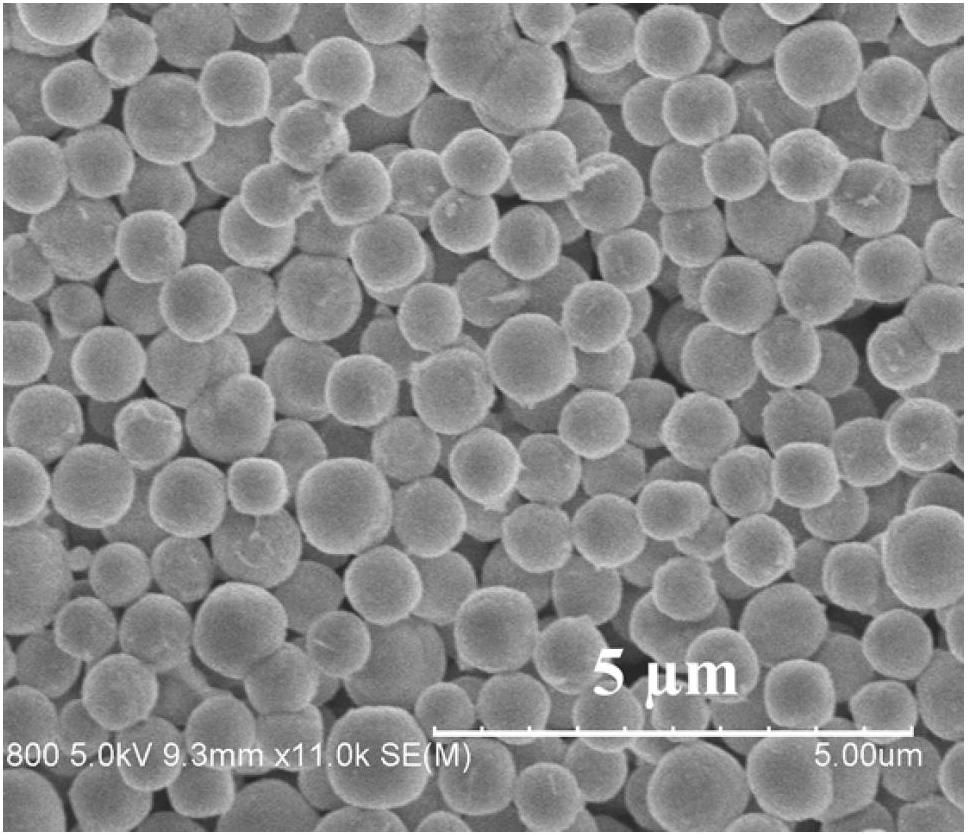

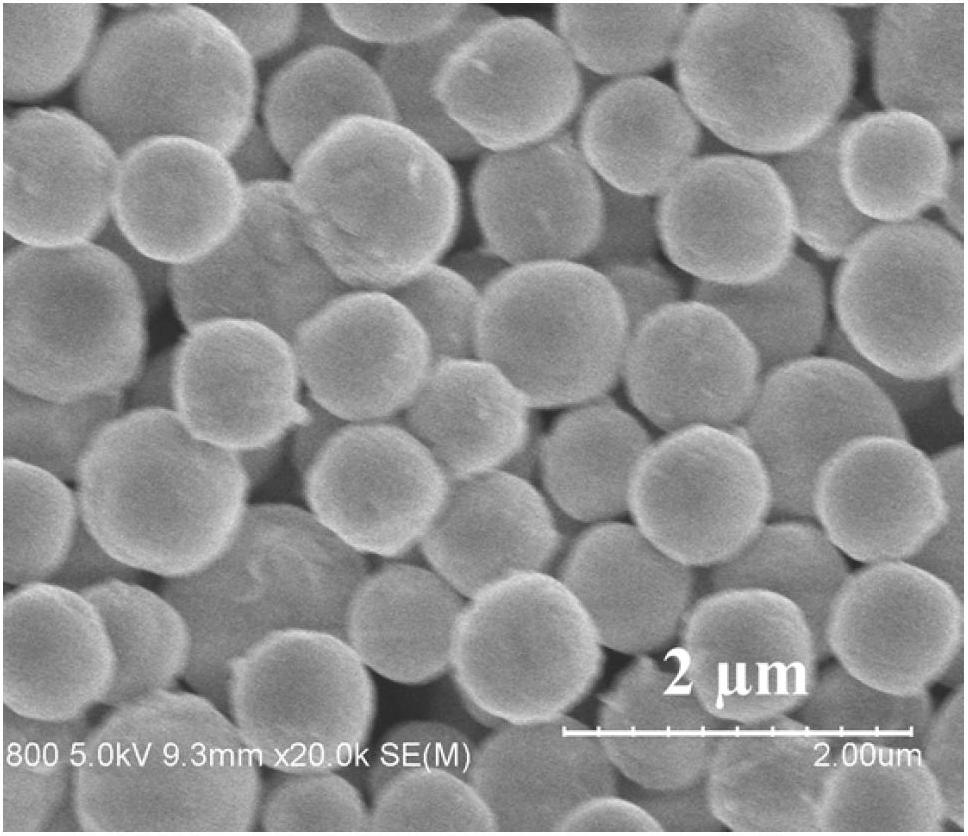

Preparation method of Sn-beta molecular sieve nanocrystal

ActiveCN110422857AGood dispersionUniform particle size distributionMaterial nanotechnologyCrystalline aluminosilicate zeolitesDispersityWater use

The invention discloses a preparation method of a Sn-beta molecular sieve nanocrystal. The preparation method comprises the following steps: mixing 0.006g-0.042g of tin tetrachloride with a solution of 4.21g-20g of tetraethylammonium hydroxide with a mass fraction of 35%, and conducting drying at 40-90 DEG C for 30-720 minutes, so as to obtain a mixed solution; uniformly mixing the mixed solutionwith 1g-5g of white carbon black, so as to obtain a mixture; carrying out crystallization on the mixture under a steam-assisted condition, so as to obtain a crystallization product; and sequentially cooling, washing, drying and calcining the crystallization product, so as to obtain the high-crystallinity Sn-beta molecular sieve nanocrystal. The synthetic steps of the preparation method are simple,seed crystals are not used, F ions are not introduced, the complete crystallization can be realized in a short time, the prepared Sn-beta molecular sieve nanocrystal is good in dispersity and uniformin particle size distribution, and meanwhile, the use amounts of a template agent and water used in the synthetic process are low, so that the method further has the advantages of being low in cost and environmental pollution, beneficial to industrial production and the like.

Owner:NORTHEASTERN UNIV

Efficient energy-saving novel nanometer material electrothermal film

InactiveCN102685943AHigh selectivityImprove thermal efficiencyHeating element materialsGlycerolWorking temperature

The invention relates to an efficient energy-saving novel nanometer material electrothermal film which comprises (mass percentage): 10-25% of tin chloride, 2-8% of nickel chloride, 10-20% of ferric oxide, 5-10% of titanium tertrachloride, 2-5% of sodium chloride, 10-15% of stannic oxide, 5-10% of hydrochloric acid, 5-15% of glycerol and 20-40% of ionized water. Electrothermal film processing liquid is prepared by mixing, stirring and heating tin chloride, nickel chloride, ferric oxide, titanium tertrachloride, sodium chloride, stannic oxide, hydrochloric acid, glycerol and ionized water at high speed. Then physical vapor deposition (PVD) technology is used for depositing the electrothermal film processing liquid on a base material to form the nanometer electrothermal film, and then a nanometer electrothermal film end product is obtained by coating silver oxide slurry at two ends of a nanometer electrothermal film semi-product and baking. The efficient energy-saving novel nanometer material electrothermal film is high in working temperature, wide in application range, long in service life, high in cost performance and efficiency and simple in manufacture method.

Owner:广东新信德节能环保有限公司

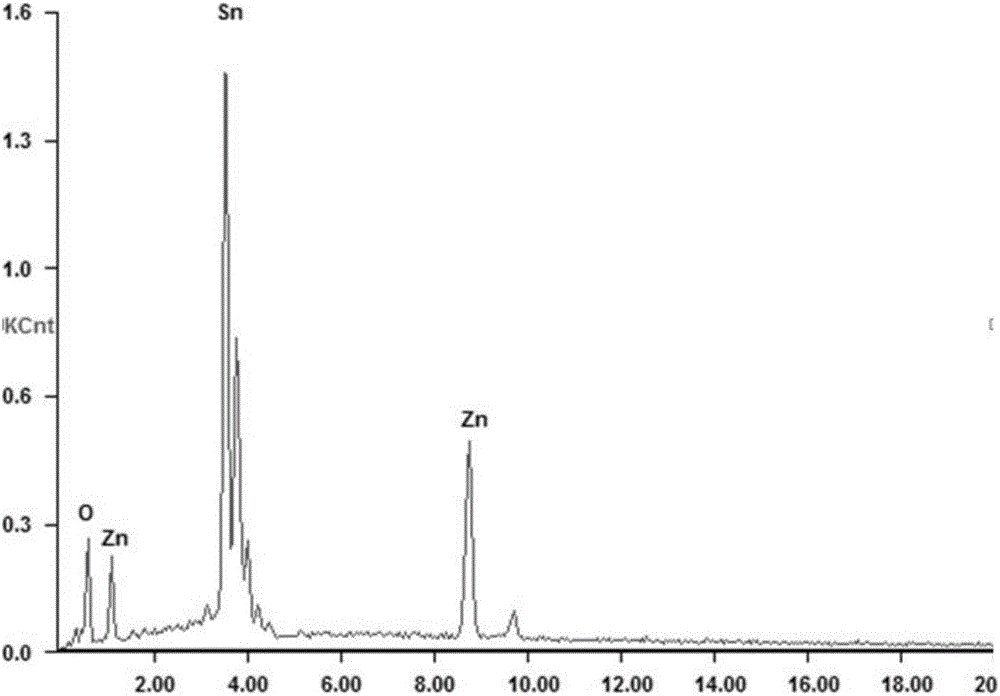

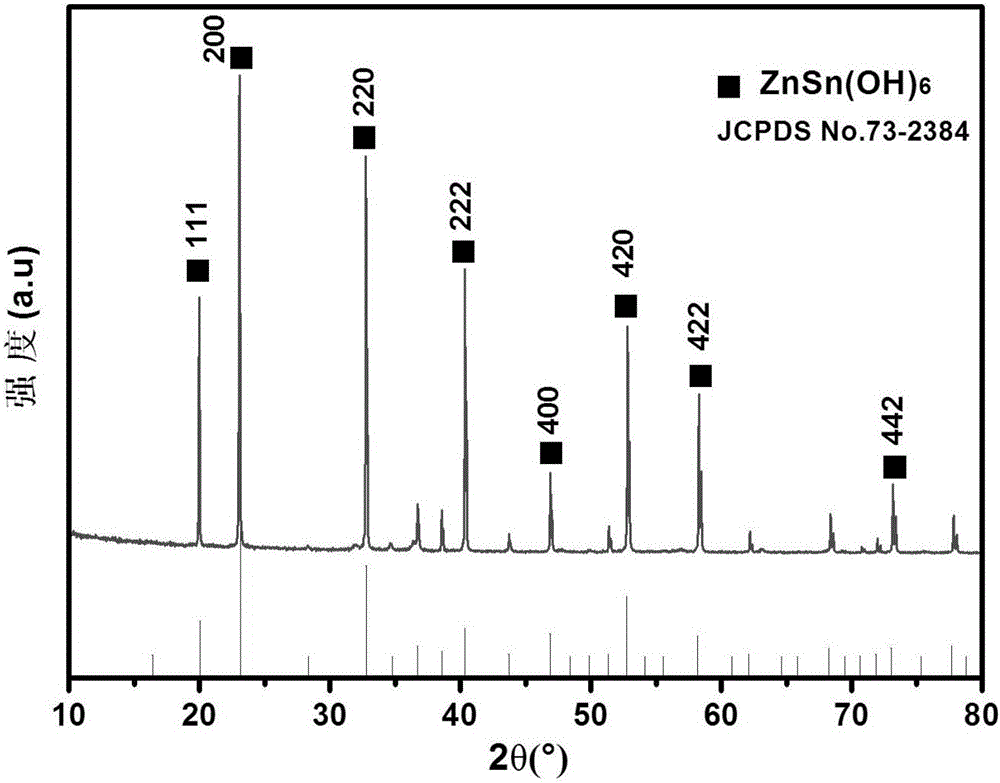

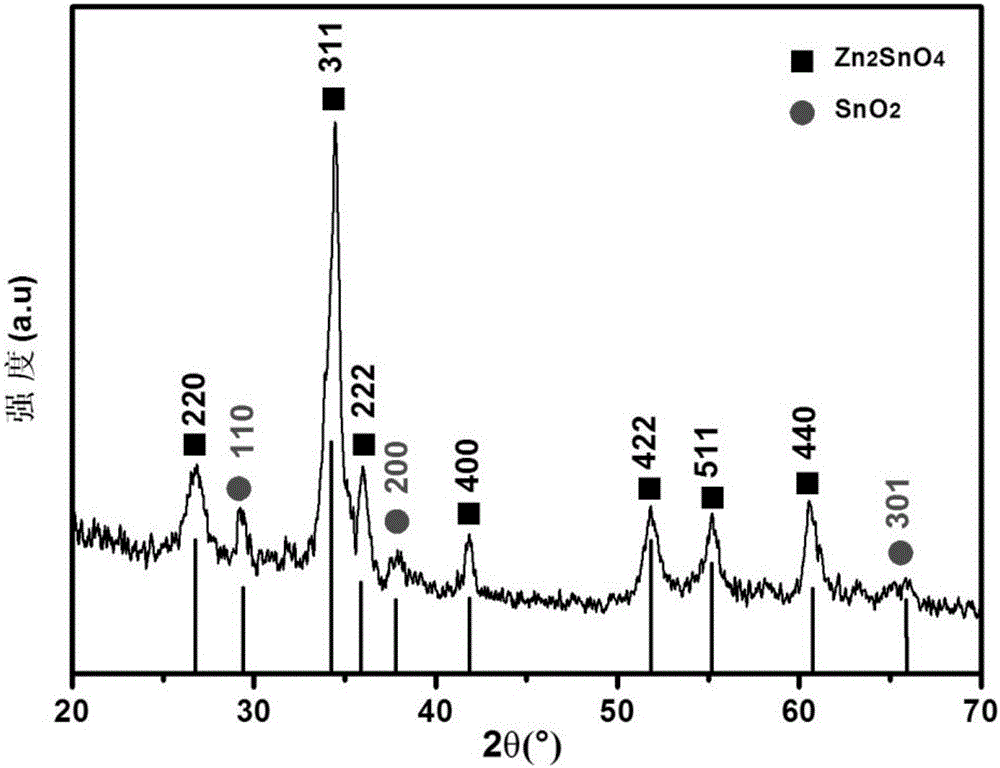

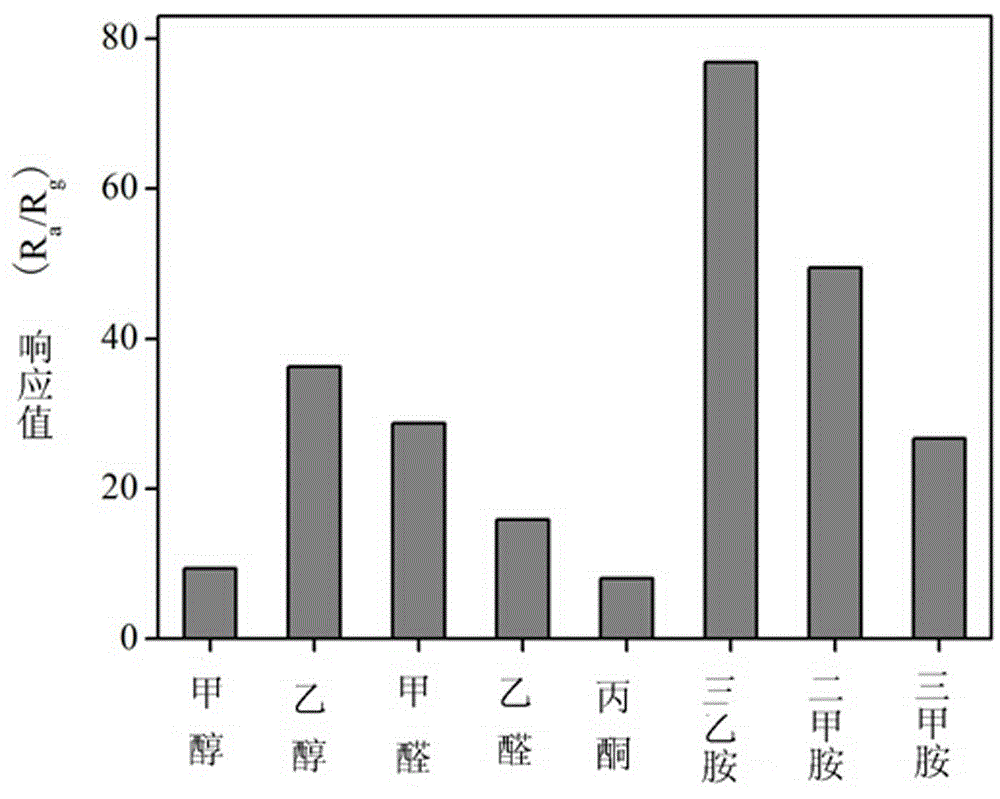

Octahedral metal oxide composite material and preparation and application thereof

InactiveCN105738450AHigh yieldReaction temperatureMaterial analysis by electric/magnetic meansAir atmosphereOctahedron

The invention discloses an octahedral metal oxide composite material and preparation and application thereof. The octahedral metal oxide composite material is formed by roasting a ZnSn(OH)6 octahedron of 1-6 micrometers and composed of a Zn2SnO4 / SnO2 octahedron. The preparation method comprises the steps that, a mixed aqueous solution of zinc salt and citric acid is added to an aqueous solution of tin tetrachloride, stirring and mixing are conducted to be uniform, a NaOH solution with appropriate concentration is added, a vigorous stirring reaction is conducted for 4-6 h at 10-90 DEG C, centrifugating, washing and drying are conducted, and the ZnSn(OH)6 octahedron with the size ranging from 1 micrometer to 6 micrometers is obtained; the octahedron is put in an air atmosphere at the temperature of 550-750 DEG C, roasting treatment is conducted for 2-6 h, and white solid powder is obtained. According to the octahedral metal oxide composite material and preparation and application thereof, the ZnSn(OH)6 octahedron material is prepared through a coprecipitation method, the reaction condition is mild, operation is easy, the cost is low, environmental friendliness is achieved, the obtained product is uniform in size, dispersion is good, the yield is high, and excellent selectivity on VOCs gases of methanal and the like is achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Manufacturing method and formula of graphene far-infrared heating plate

ActiveCN111447695AWavelength stableGood for healthOhmic-resistance electrodesHeating element materialsIndium TrichlorideAlcohol

The invention discloses a manufacturing method and a formula of a graphene far-infrared heating plate. A solution is divided into a main solution, an additive and deionized water. The manufacturing method of the main solution comprises the following steps: putting 20-100g of graphene, 1-10g of stannic chloride (SnCl4), 1-15g of indium trichloride (InCl3) and 1-10g of ammonium fluoride (NH4F) intoa container; and pouring 100-200 mL of absolute ethyl alcohol (EtOH), stirring for 1-3 hours, and standing for 5-30 hours to obtain the main solution. The additive is poured into a main solution container, and the solution is stirred for 10-60 minutes, then 5-30 mL of a hydrochloric acid is added, the solution is stirred for 10-60 minutes, and then the solution stands for 5-15 hours for later use.The hydrochloric acid is added to play a role of a stabilizer, and a far infrared spectrum wavelength of the heating plate is stabilized within the range of 4-14 micrometers by the additive.

Owner:中山市烯帝科技有限公司

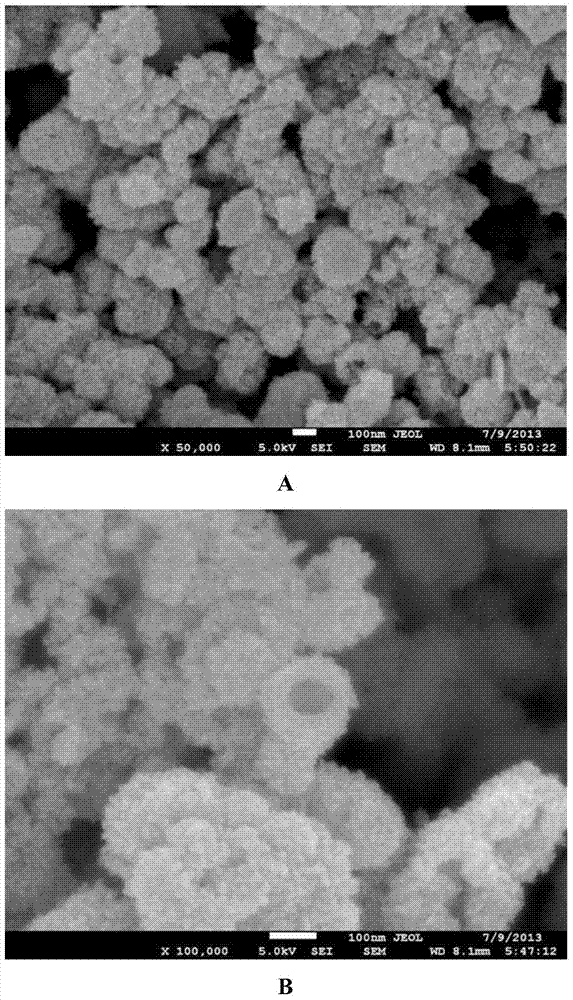

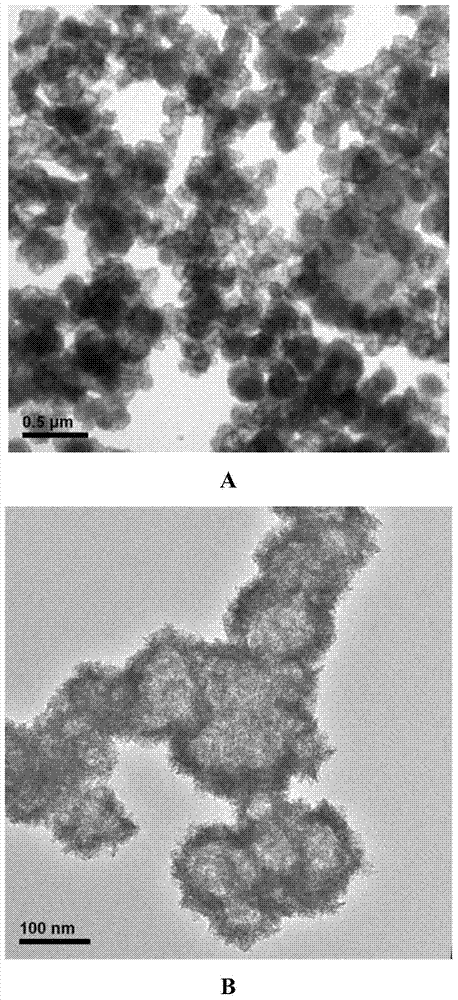

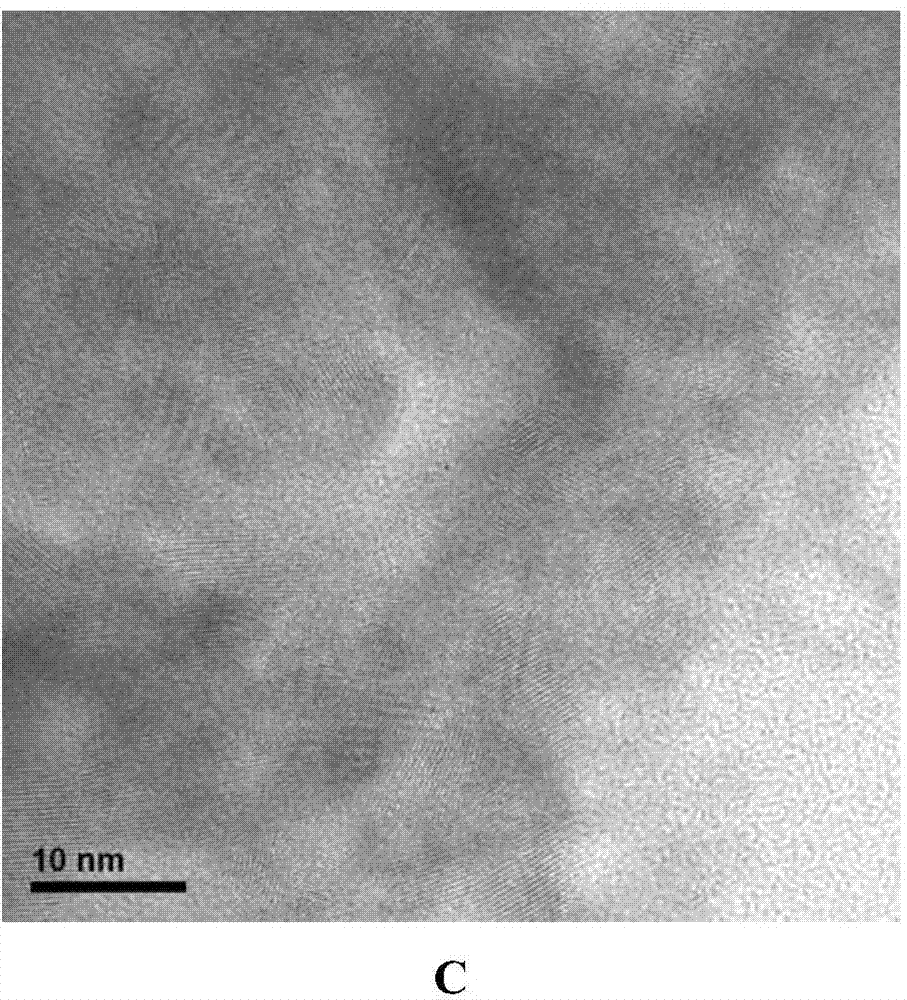

Preparation method for spherical tin dioxide self-assembled from nano-fragments

ActiveCN104556209AHigh purityUniform particle sizeMaterial nanotechnologyTin oxidesTin dioxideAcetic acid

The invention relates to preparation for tin dioxide, and specifically discloses a preparation method for spherical tin dioxide self-assembled from nano-fragments. The preparation method comprises the following steps: (1) dissolving 3-4g of stannic chloride in 50-55ml of ethanol, adequately dissolving, then adding 1-2g of terephthalic acid, then adding hydrofluoric acid or hydrochloric acid or formic acid or acetic acid, and further stirring to adequately mix; (2) transferring the mixed solution obtained in the step (1) in a reaction kettle, and reacting for 12-14h at a constant temperature of 220 DEG C; (3) cooling the reaction kettle, then taking out a sample, and performing centrifuging, washing and drying treatment, thereby obtaining the product. The method is simple in preparation process, convenient to operate, and easy for process parameter control; the spherical tin dioxide self-assembled from the nano-fragments is uniform in granularity, high in dispersity, and can be used for air-sensitive detection for low-concentration volatile organic compounds.

Owner:TAIYUAN UNIV OF TECH

Ozone gas-sensitive material, preparation method thereof, ozone gas-sensitive device, preparation method of ozone gas-sensitive device

ActiveCN108609667AReduce sensitivityHigh selectivityMaterial analysis by electric/magnetic meansCobalt oxides/hydroxidesAqueous solutionCitric acid

The invention relates to an ozone gas-sensitive material, a preparation method thereof, an ozone gas-sensitive device and a preparation method of the ozone gas-sensitive device. The ozone gas-sensitive material is Co3O4 nano-powder, and has hollow cubic structure and particle size of the material is 100-250 nm. The preparation method of the gas-sensitive material comprises the following steps: mixing an aqueous solution of tin chloride and an aqueous solution of citric acid to obtain a solution I; mixing an aqueous cobalt chloride solution with the solution I, adding NaOH or KOH, performing stirring, adding NaOH or KOH again, performing stirring to obtain a mixed solution, wherein the molar ratio of NaOH or KOH added for the first and second time to tin chloride is 6-10:1 and 30-50:1 respectively; conducting hydrothermal reaction on the mixed solution, filtering, washing and drying a reaction product to obtain a precursor, and heating and calcining the precursor to obtain the Co3O4 nano-powder. The gas-sensitive material has high sensitivity and good selectivity to ozone, and the prepared gas-sensitive device has a detection function that is highly sensitive to ozone gas.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

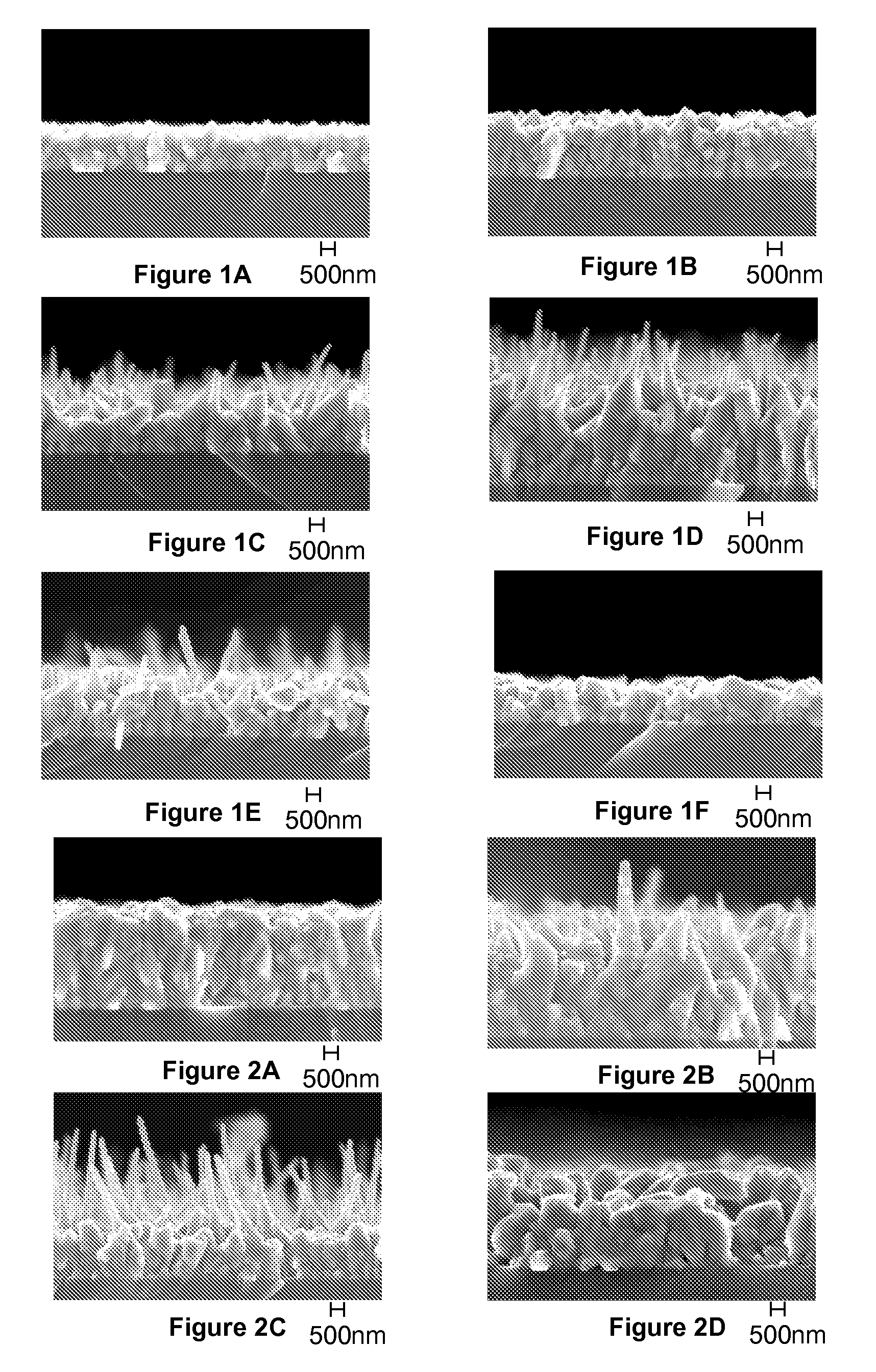

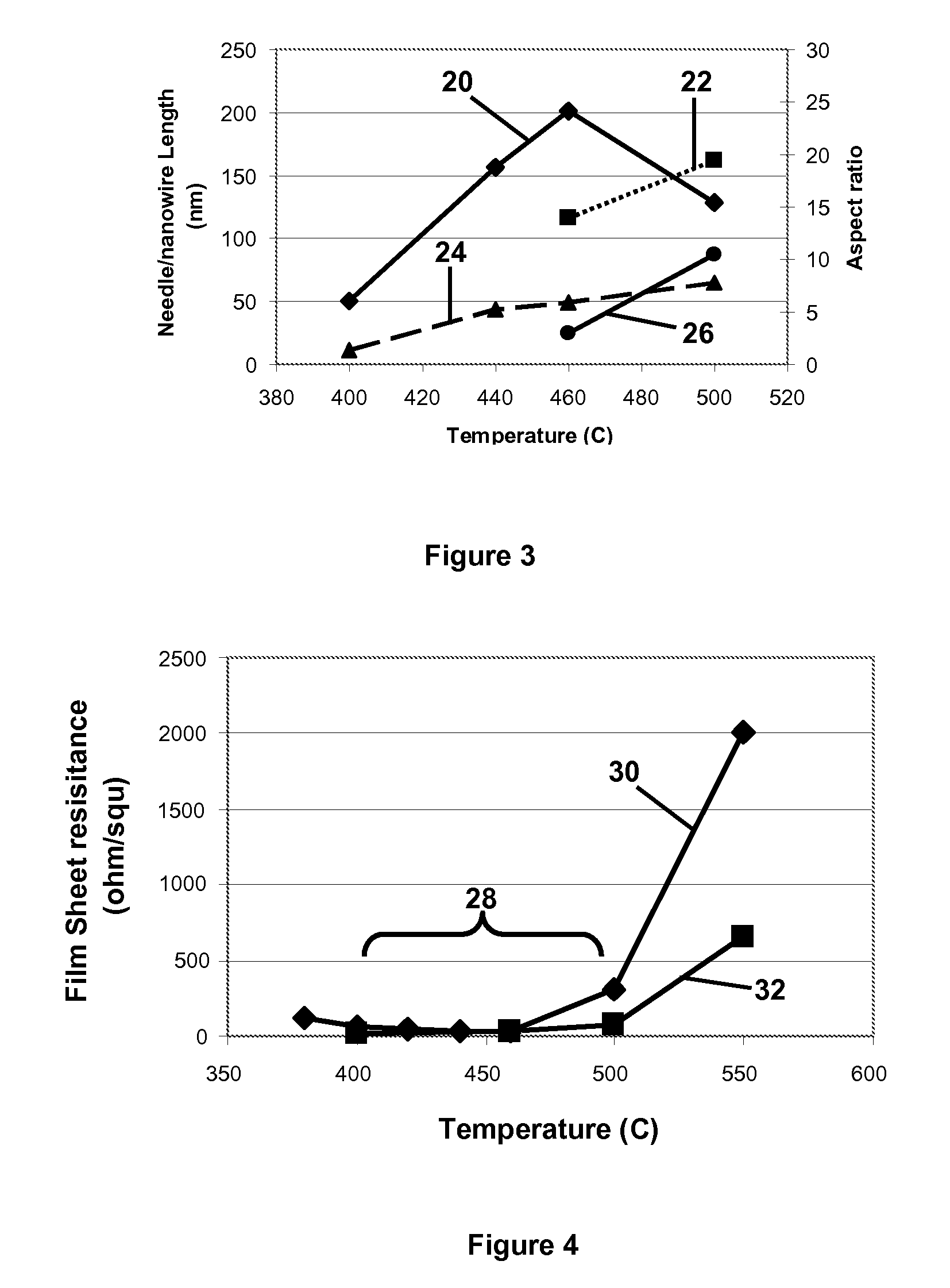

Nano-whisker growth and films

Methods for making tin oxide films comprising nano-whiskers comprises providing a solution comprising a tin precursor and a solvent; preparing aerosol droplets of the solution; and applying the aerosol droplets to a heated glass substrate, converting the tin chloride to tin oxide to form a tin oxide film on the glass substrate, wherein the tin oxide film comprises nano-whiskers.

Owner:CORNING INC

Ceramic gas-sensitive sensor for alcohol detection

ActiveCN104977320AIncreased sensitivityHigh sensitivityMaterial analysis by electric/magnetic meansGas detectorSlurry

The present invention discloses a ceramic gas-sensitive sensor for alcohol detection. The sensor includes a semiconductor ceramic substrate, a heating material layer, an electrode and a gas-sensitive material layer. The gas-sensitive material layer is obtained by using the following method: preparing antimony trioxide and zinc oxide into a salt solution, preparing tin chloride into a tin chloride ethanol solution, adding the salt solution to the tin chloride ethanol solution for mixed reaction, adding an appropriate amount of a chelating agent, dropwise adding ammonia solution to adjust the pH value to 9.0; filtering and recovering the precipitate, washing and sintering the precipitate to obtain a doped nano powder; weighing yttria, lanthanum oxide, doped nano powder and water, mixing and grinding into a gas-sensitive slurry; and applying the gas-sensitive slurry to the surface of semiconductor ceramic substrate to form a gas-sensitive material. Through blending the proportional change of tin, zinc and lanthanum, the sensitivity of sensitive material layer to alcohol is improved, and the sensitivity of alcohol detection is enhanced; in addition, by introducing antimony and yttrium, the resistivity of sensitive material layer is greatly reduced to ensure reliable operation of the signal analysis component.

Owner:高鑫环保科技(苏州)有限公司

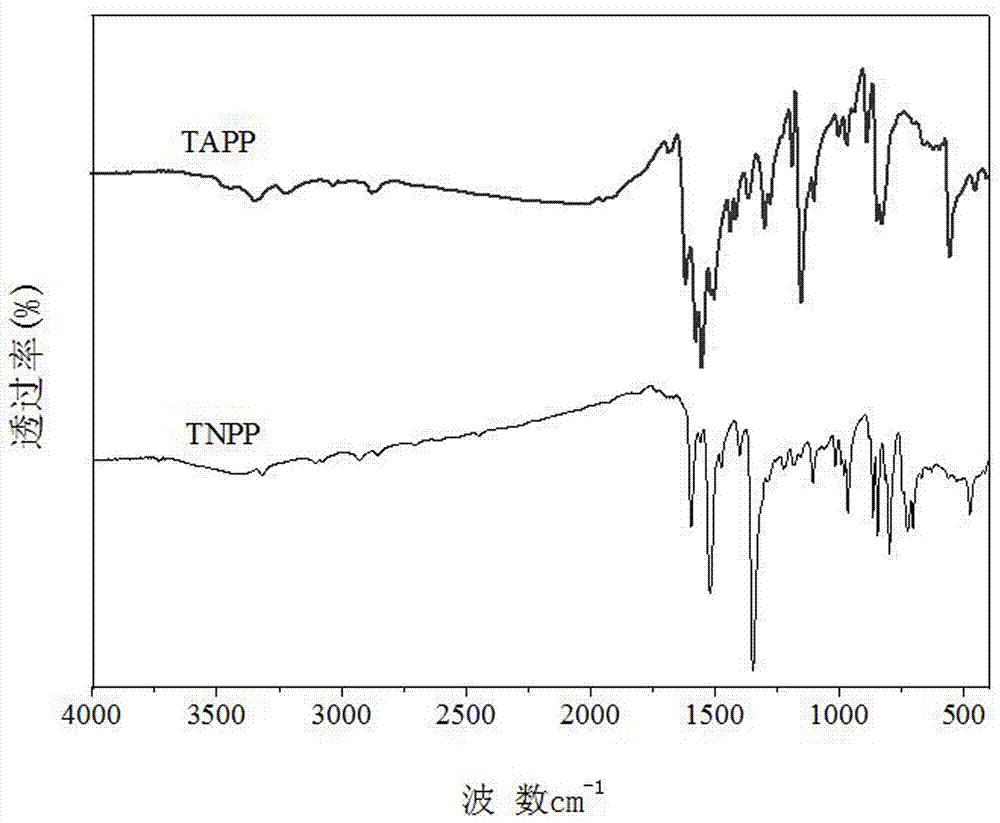

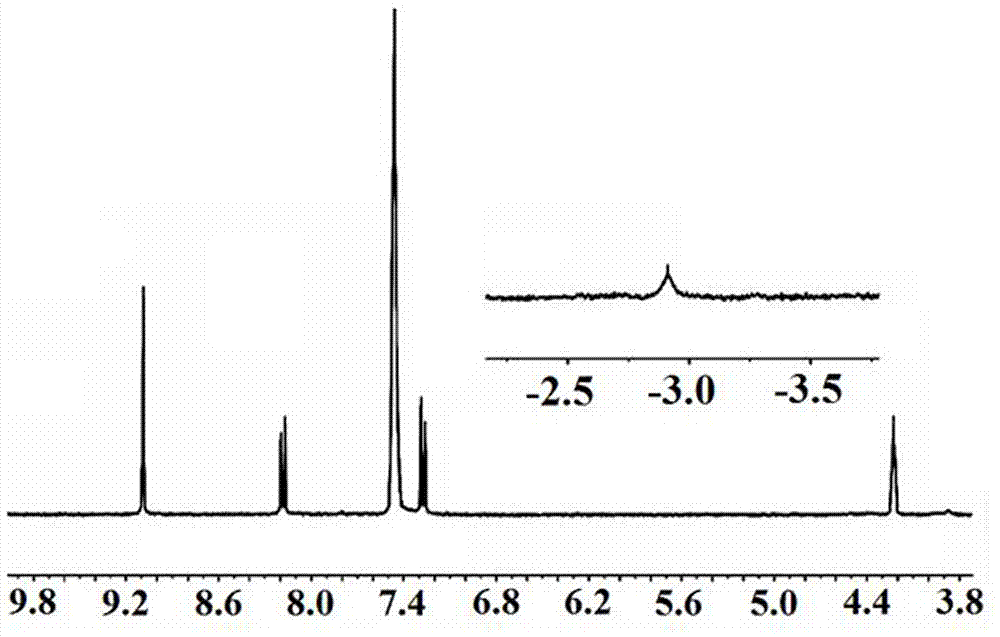

Method for synthesizing TNPP and TAPP at high yield and high efficiency

InactiveCN107056793AHigh purityIncrease reaction rateOrganic chemistryChemical synthesisPropionic anhydride

The invention provides a method for synthesizing TNPP and TAPP at high yield and high efficiency and belongs to the technical field of chemical synthesis. The method provided by the invention is characterized in that a small amount of acetic anhydride or propionic anhydride is added to serve as a catalyst in the reaction process of nitrobenzaldehyde and pyrrole, so that the reaction speed is effectively improved and the reaction is performed rightwards to the maximum extent; hot pyrrole is adopted for dissolving and purifying the TNPP to obtain a TNPP product with high purity; in the process of synthesizing the TAPP, a strong reducer tin chloride is adopted for ammonifying the TNPP, and trichloromethane capable of dissolving the TAPP is adopted for efficiently separating the TAPP from an organic phase by adopting a Soxhlet extraction method, so that the purity and the yield of the TAPP are effectively improved.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for preparing Cu-Zn-Sn-S nano hollow spheres

ActiveCN104261461AUniform structureSmall particlesMaterial nanotechnologyTin compoundsSolar batteryCuprous chloride

The invention discloses a method for preparing Cu-Zn-Sn-S nano hollow spheres. The method comprises the following steps: (1) preparing a mixed water solution of cuprous chloride and thioacetamide; (2) preparing a mixed water solution of stannic chloride and thioacetamide; (3) preparing a mixed water solution of stannic chloride and thioacetamide; (4) mixing the following components by volume: 4.5-5.5 parts of the mixed solution of the step (1), 4.5-5.5 parts of the mixed solution of the step (2) and 14-16 parts of the mixed solution of the step (3), and stirring; and (5) centrifuging the reaction liquid of the step (4), and drying, thereby obtaining the product. As the process is simple, the raw materials are simple and easy to obtain, the method for preparing the Cu-Zn-Sn-S nano hollow spheres is easy for industrialization popularization; the prepared Cu-Zn-Sn-S nano hollow spheres are uniform in structure, fine in granule and wide in application prospect in fields such as solar batteries, photocatalytic hydrogen generation and lithium battery cathode materials.

Owner:重庆感知科技孵化器有限公司

Acid-base indicator and preparation method thereof

ActiveCN103196907AStable structureDiscoloration point close to neutralMaterial analysis by observing effect on chemical indicatorFiltrationNitration

The invention relates to an acid-base indicator having a structural formula as described in the specification and a preparation method thereof. The preparation method is characterized by comprising the following steps: placing a phenol derivative and a product of a reaction of saccharin with a nitration reagent in a reactor; adding fuming tin chloride under the protection of nitrogen; carrying out heating for a reaction; adding an acid solution to dissolve tin chloride and excess phenol derivative after the reaction; carrying out hot filtration to obtain a precipitate; dissolving the obtained precipitate with an NaOH solution with a concentration of 1 mol / L; carrying out filtration and acidifying an obtained filtrate with an acid; and subjecting obtained deposition to recrystallization so as to prepare the acid-base indicator. The acid-base indicator has the characteristics of easy synthesis, an approximately neutral color transition point, sensitive color transition, a stable structure and the like.

Owner:JIANGNAN UNIV

High-efficiency formaldehyde removing spray preparation method

InactiveCN108434986AImprove formaldehyde removal efficiencyThe process of removing formaldehyde is green and environmentally friendlyGas treatmentDispersed particle separationHazardous substanceUltraviolet

The invention relates to a high-efficiency formaldehyde removing spray preparation method. The method comprises the following specific operation steps: 1) weighing stannic chloride, titanium tetrachloride and ethyl alcohol and adding the titanium tetrachloride into the ethyl alcohol to perform alcoholysis; dropwise adding acetic acid to adjust a pH to be equal to 2 to 3 and stirring to make the acetic acid fully react; then adding the stannic chloride into a solution to perform secondary alcoholysis and stirring to make the stannic chloride fully react; 2) warming the solution and keeping fora period, then dropwise adding ammonium hydroxide to adjust a pH to be about 7, precipitating to obtain solid powder, centrifuging and washing the solid powder and drying and roasting under high temperature to obtain tin doped nano titanium dioxide powder; 3) mixing the powder, negative ion powder, a dispersant and deionized water, adding into a nano grinding machine, controlling an appropriate grinding condition and finally preparing dispersion liquid, namely the high-efficiency for formaldehyde removing spray disclosed by the invention. The high-efficiency formaldehyde removing spray prepared by the method disclosed by the invention has a high formaldehyde removing efficiency, not only has a high formaldehyde removing efficiency under ultraviolet irradiation, but also has a higher formaldehyde removing efficiency under visible light irradiation; furthermore, formaldehyde removal is effective for a long time, a formaldehyde removing process achieves greenness and environmental friendliness, and no toxic and harmful matter is generated.

Owner:常州德维勒新材料科技有限公司

Preparing method for polishing powder used for polishing of zirconium dioxide ceramic

InactiveCN104694018APolishing friction hardness increasedSmall median diameterPolishing compositions with abrasivesNitrateMicrometer

The invention discloses a preparing method for polishing powder used for polishing of zirconium dioxide ceramic. The preparing method is characterized by comprising the following technological steps: 6%-12% by mass of ceros nitrate is added in a reactor, 22%-32% by mass of stannic chloride is dissolved into water, 6%-13% by mass of calcium carbonate, 3%-7% by mass of silicon dioxide, 38%-48% by mass of silicon nitride are further added, stirring is carried out, seriflux is formed, 3%-10% by mass of ammonium hydroxide is further added during the stirring process, and the sum of the percents, except water, is 100%. Under the normal pressure and temperature, stirring reaction is carried out for 2-4 h, solid-liquid separation is carried out, washing is carried out, calcinations is carried out for 10-12h at the temperature ranging from 1000 DEG C to 1100 DEG C, after cooling is carried out, smashing is carried out through airflow, the polishing powder of the zirconium dioxide ceramic is obtained, and the particle size of the obtained polishing powder of the zirconium dioxide ceramic ranges from 0.2 to 2.0 micrometers. The polishing powder has the advantages of being high in grinding rigidity, good in powder polishing effect, high in glossiness, free of scratch, high in flatness, and low in powdery usage amount.

Owner:UNIV OF JINAN

Butanol gas sensitive material and preparation method thereof, and butanol gas sensitive device and preparation method thereof

ActiveCN108609664AReduce sensitivityHigh selectivityMaterial analysis by electric/magnetic meansNanotechnologyFiltrationAqueous solution

The invention relates to a butanol gas sensitive material and a preparation method thereof, and a butanol gas sensitive device and a preparation method thereof. The butanol gas sensitive material is aCoSnO3 nano-powder and of a hollow cube structure, and has particle size of 80 to 150 nm. The preparation method of the gas sensitive material comprises the following: a stannic chloride aqueous solution and a citric acid solution are mixed to obtain solution I; a cobalt chloride aqueous solution is mixed with the solution I, NaOH or KOH is added and stirred, and NaOH or KOH is added again and stirred to obtain a mixed solution, wherein the molar ratios of NaOH or KOH added first and NaOH or KOH added second to stannic chloride are 6-10 to 1 and 12-16 to 1 respectively; the mixed solution issubject to hydrothermal reaction, a reaction product is subject to suction filtration, washing and drying to obtain a precursor, and the precursor is heated and calcined to obtain a cobaltous stannatenano-powder. The gas sensitive material has high sensitivity and good selectivity to butanol, and the prepared gas sensitive device has the detection function which is highly sensitive to butanol gas.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Neodymium and antimony codoped stannic oxide nano-powder and preparation and application thereof

ActiveCN106219598ASmall particle sizeUniform particle size distributionAntimony oxides/hydroxides/oxyacidsMaterial analysisDissolutionCalcination

The invention relates to a preparation method of neodymium and antimony codoped stannic oxide nano-powder. The preparation method comprises the steps that stannic chloride, antimony chloride, neodymium nitrate and ethyl alcohol are weighed, and stannic chloride is added into ethyl alcohol; neodymium nitrate is added into a solution, and stirring is conducted for sufficient dissolution; antimony chloride is added into the above-mentioned solution, and stirring is conducted for sufficient dissolution; the solution is warmed up, warming is kept for a period of time, ammonia water is dropwise added to adjust the PH to be about 7 so as to obtain solid powder, the solid powder is subjected to centrifugal washing, drying and high-temperature calcination, and neodymium and antimony codoped stannic oxide is obtained. Neodymium and antimony codoped stannic oxide obtained through the method is small in particle size and uniform in particle size distribution and has the excellent gas-sensitive sensitivity to acetone.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Flux compositions for steel galvanization

This invention relates to a flux composition for treating a metal surface, comprising (a) more than 40 and less than 70 wt. % zinc chloride, (b) 10 to 30 wt. % ammonium chloride, (c) more than 6 and less than 30 wt. % of a set of at least two alkali metal chlorides including sodium chloride and potassium chloride, (d) from 0 to 2 wt. % lead chloride, and (e) from 0 to 15 wt. % tin chloride, provided that the KCl / NaCl weight ratio of said set of at least two alkali metal chlorides ranges from 2.0 to 8.0.This invention also relates to a fluxing bath comprising this flux composition dissolved in water for use in galvanizing processes, by batch or continuously, of metal articles such as iron or steel long products and flat products including wires, plates, coils, rods, reinforcing bars, tubes, strips and sheets.

Owner:FONTAINE HLDG NV

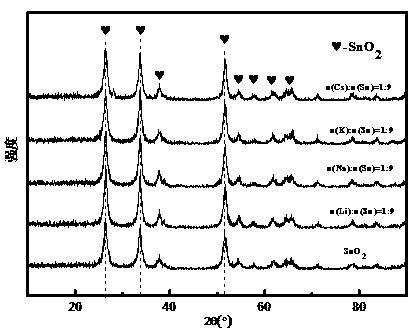

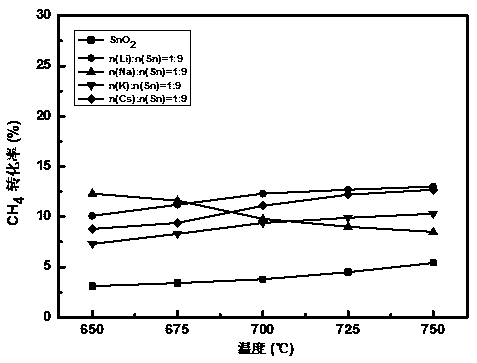

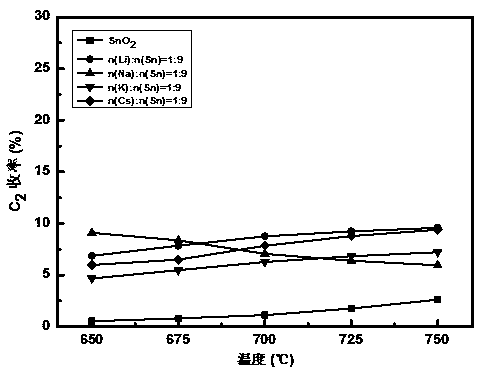

Preparation method and application of alkali metal modified tin dioxide catalyst for methane oxidative coupling

InactiveCN107754780ALow costLow equipment requirementsCatalystsHydrocarbon preparation catalystsTin dioxideTotal dissolved solids

The invention provides a preparation method and application of an alkali metal modified tin dioxide catalyst for methane oxidative coupling. The preparation method comprises the following steps: regulating the pH (Potential of Hydrogen) value of a tin chloride pentahydrate water solution to 7 by utilizing ammonia water with the mass percent of 25 percent to 28 percent until Sn<4+> ions are completely precipitated; then carrying out suction filtering and washing with de-ionized water until TDS (Total Dissolved Solids) is less than 10; then drying and roasting to obtain an SnO2 carrier; and adding the SnO2 carrier into a proper amount of alkali metal nitrate solution and drying and roasting to prepare the catalyst with the mol ratio of n(M) to n(Sn) of x to (10-x), wherein M is Li, Na, K orCs. The catalyst prepared by the preparation method provided by the invention has good low-temperature performance and stability in reaction for preparing ethane and ethylene by simulating the methaneoxidative coupling. The preparation method takes cheap metal salt as a raw material and the related catalyst is prepared by adopting an equal-volume immersion method. The catalyst has the advantagesof low production cost, simple synthesis technology, easiness of controlling a synthesis process and the like.

Owner:NANCHANG UNIV

Pucherite-stannic oxide complex photocatalyst as well as preparation method and application thereof

ActiveCN105032399AHigh catalytic activityLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsMethyl blueRoom temperature

The invention discloses a pucherite-stannic oxide complex photocatalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) dissolving tin chloride and bismuth nitrate in a nitric acid solution, fully stirring, and then preparing the solution into an acid mixed solution; dissolving ammonium metavanadate in a sodium hydroxide solution, fully stirring, and preparing an alkaline sodium vanadate solution; (2) under the stirring condition, dropwise adding the mixed solution into the sodium vanadate solution, so that a luminous yellow solution is generated; (3) dropwise adding an alkaline solution into the luminous yellow solution, adjusting the PH value to be above 8, performing supersonic vibration, and performing hydrothermal reaction on the mixed solution; (4) when a hydrothermal product is cooled to room temperature, cleaning by using deionized water, filtering, and drying, so that obtained powder is the pucherite-stannic oxide complex photocatalyst. The preparation method is simple, the cost is low, the repeatability is good, and the mass production requirement can be well met; the prepared photocatalyst can perform photocatalytic degradation on methyl blue under visible light.

Owner:SOUTH CHINA UNIV OF TECH

High-performance soldering flux

InactiveCN104923975AEasy to removeQuality improvementWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherEthyleneglycol monobutyl ether

A high-performance soldering flux is made from the following raw materials, by weight, 6-13 parts of citric acid, 4-7 parts of triethanolamine, 2-7 parts of nitroethane,7-9 parts of pentaerythritol oleate, 6-8 parts of diethylene glycol monobutyl ether, 20-40 parts of tin, 1-5 parts of 2,3-dibromopropyl alcohol, 6-11 parts of dolomite, 2-6 parts of slagging agents, 1-5 parts of zinc chloride, 6-9 parts of sodium dodecyl sulfate, 2-5 parts of phenolic resin, 3-8 parts of acetone, 1-4 parts of tin chloride, 6-13 parts of salicylic acid, 2-5 parts of propanol and 6-11 parts of ethyl acetate. The high-performance soldering flux has the advantages that the high-performance soldering flux is low in toxicity and harmless, meanwhile, welding flux and oxide on the surface of welded base metal can be well removed, and welding quality is improved.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

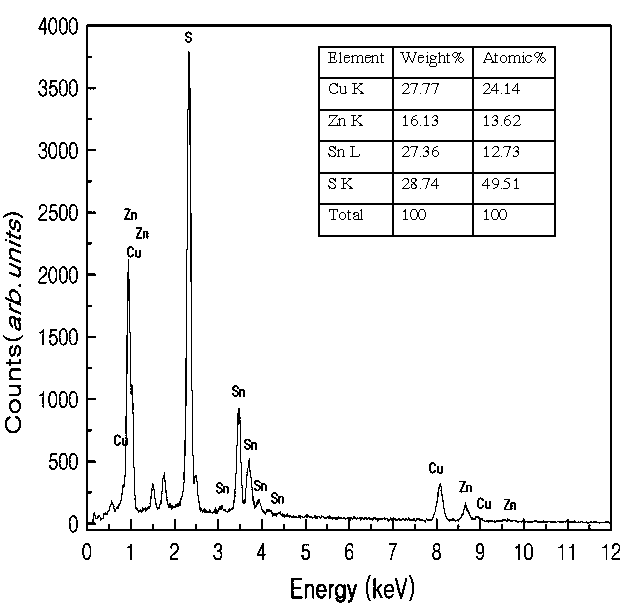

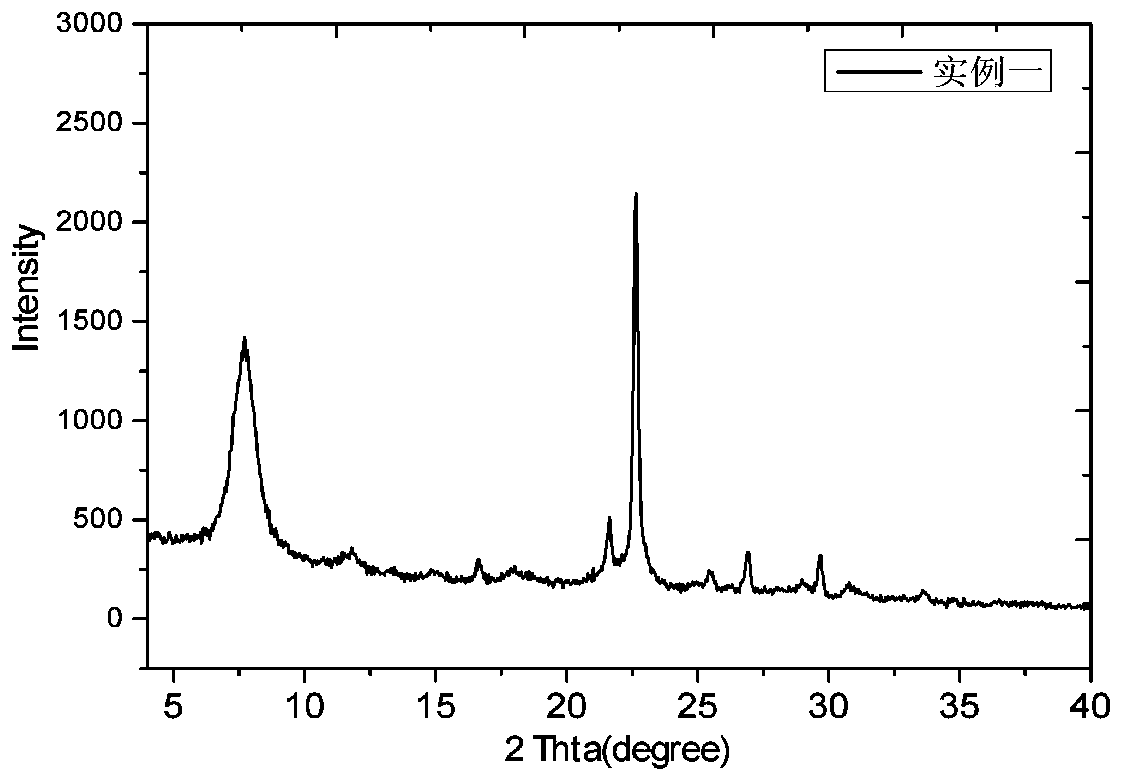

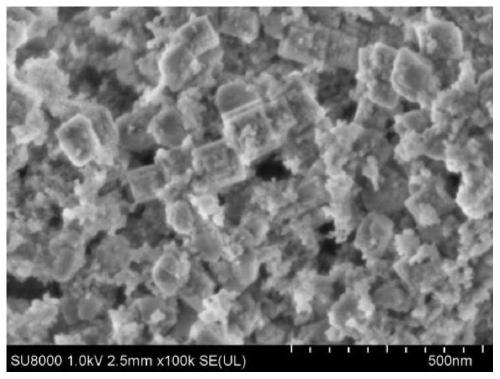

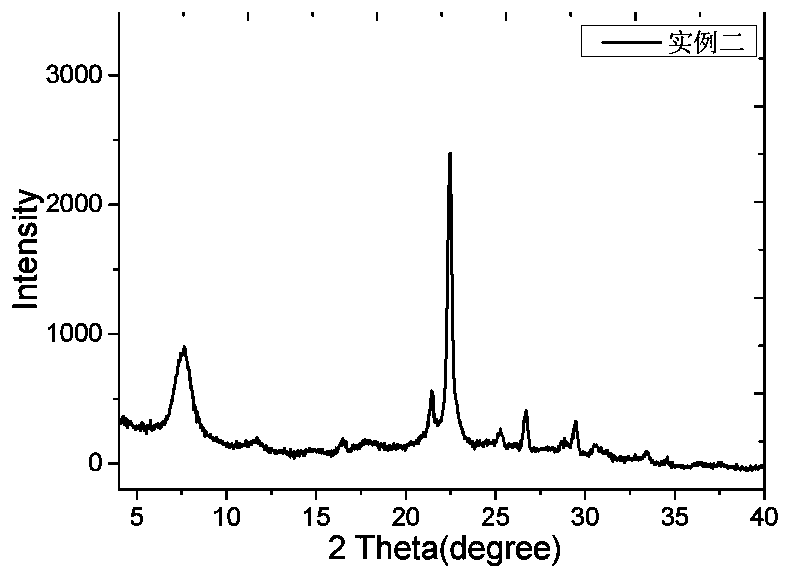

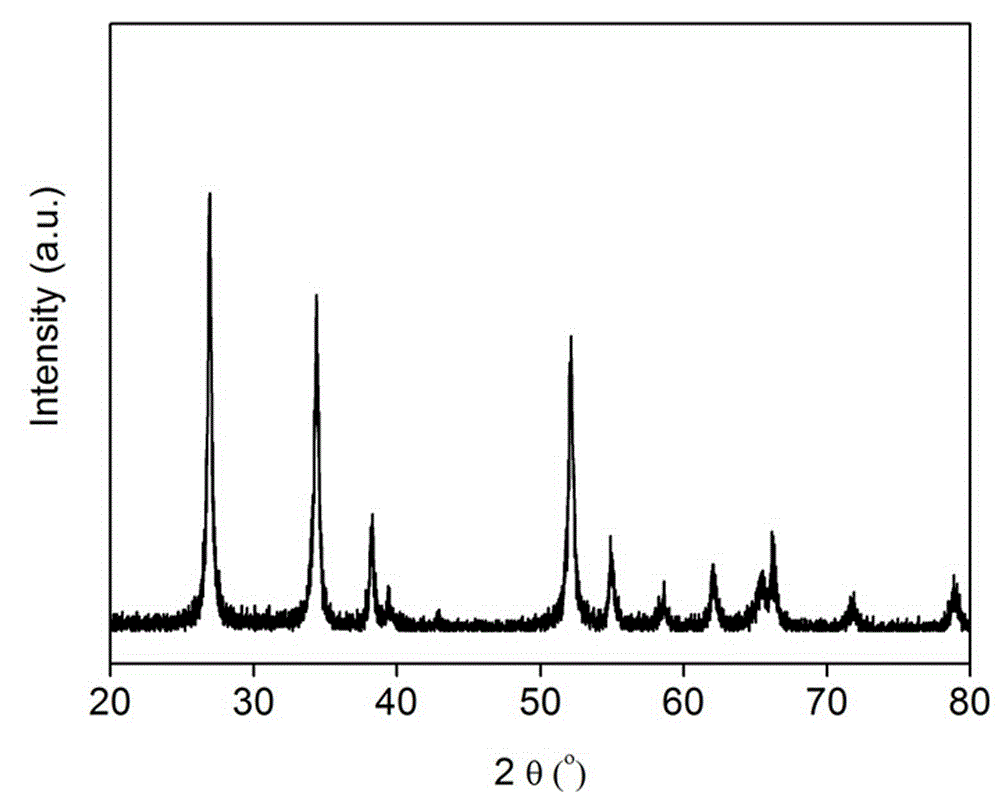

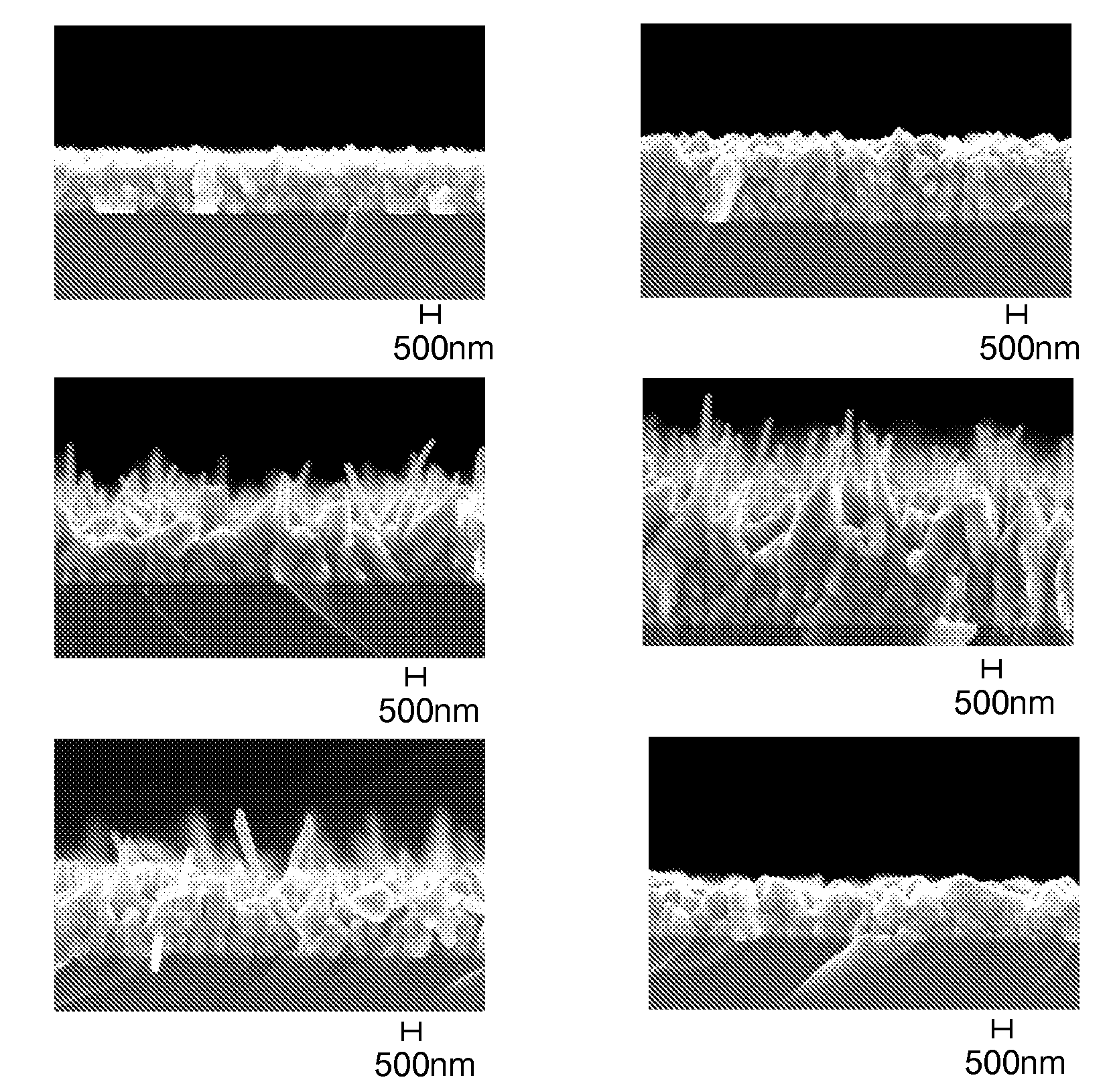

ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof

ActiveCN110931739AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyTin compoundsHydrogen atmosphereArgon atmosphere

The invention belongs to the technical field of batteries, and discloses a ZnS / SnS / antimony trisulfide [at] C hollow nanocube structure composite material, and a preparation method and application thereof. The composite material is prepared by the following steps: mixing water, tin tetrachloride, sodium citrate, zinc chloride and sodium hydroxide, washing with water, and drying to obtain H-ZHS; ultrasonically dispersing H-ZHS in an aqueous solution, adding sodium hydroxide or potassium hydroxide for etching, adding dopamine, stirring, washing with water and drying to obtain H-ZHS[at]PDA; adding H-ZHS[at]PDA and thiourea; vulcanizing in a hydrogen atmosphere at the temperature of 300-350 DEG C; cooling to room temperature, mixing the obtained H-SnS<2> / ZnS[at]PDA, antimony trichloride and absolute ethyl alcohol, carrying out hydrothermal reaction at 90-120 DEG C, washing with water, drying, carbonizing the obtained H-ZnS / SnS<2> / Sb<2>S<3>[at]PDA in an argon atmosphere at 500-530 DEG C, and cooling to room temperature, so as to obtain the H-SnS<2> / Sb<2>S<3>[at]PDA.

Owner:GUANGDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

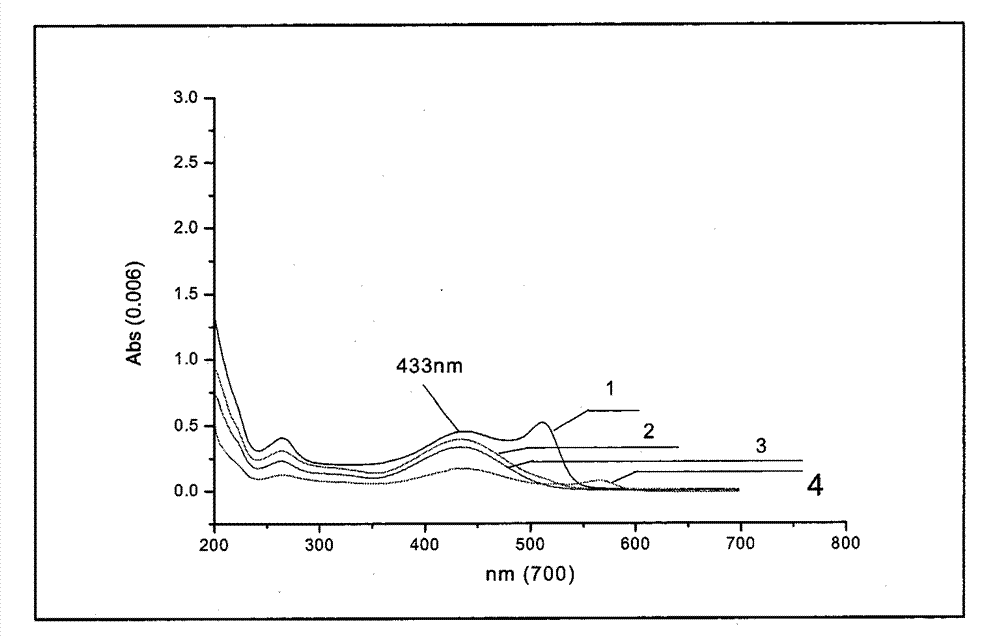

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000011.png)

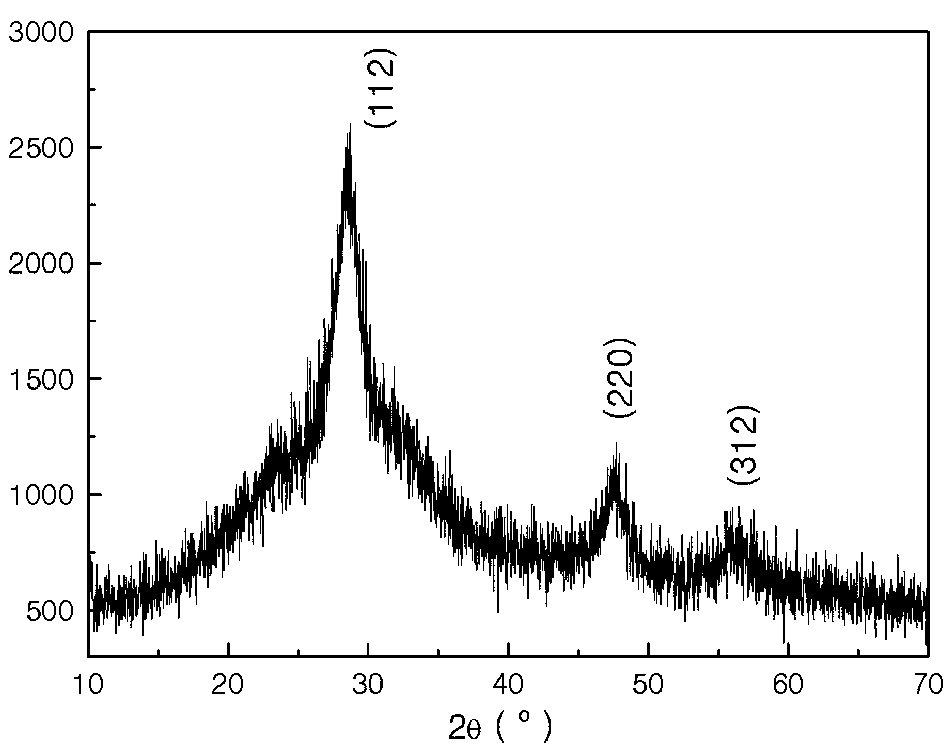

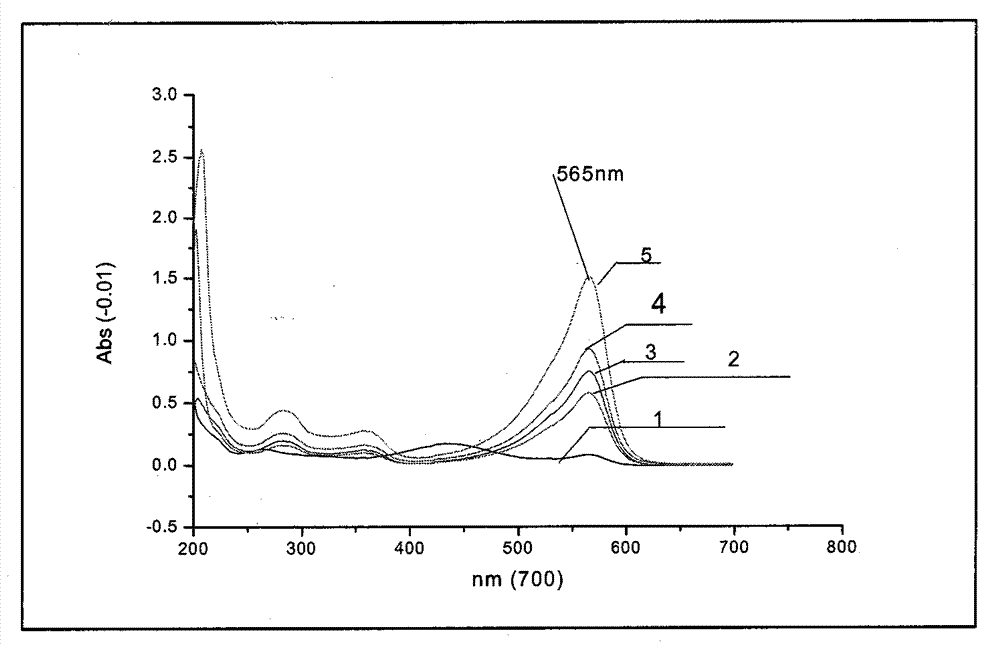

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000012.png)

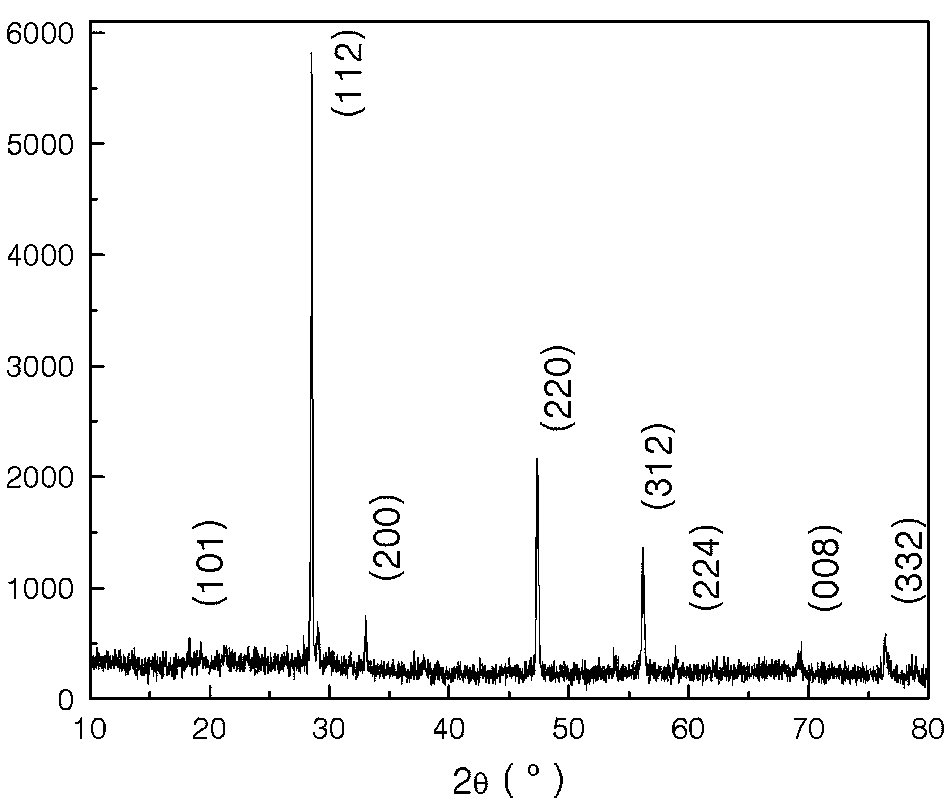

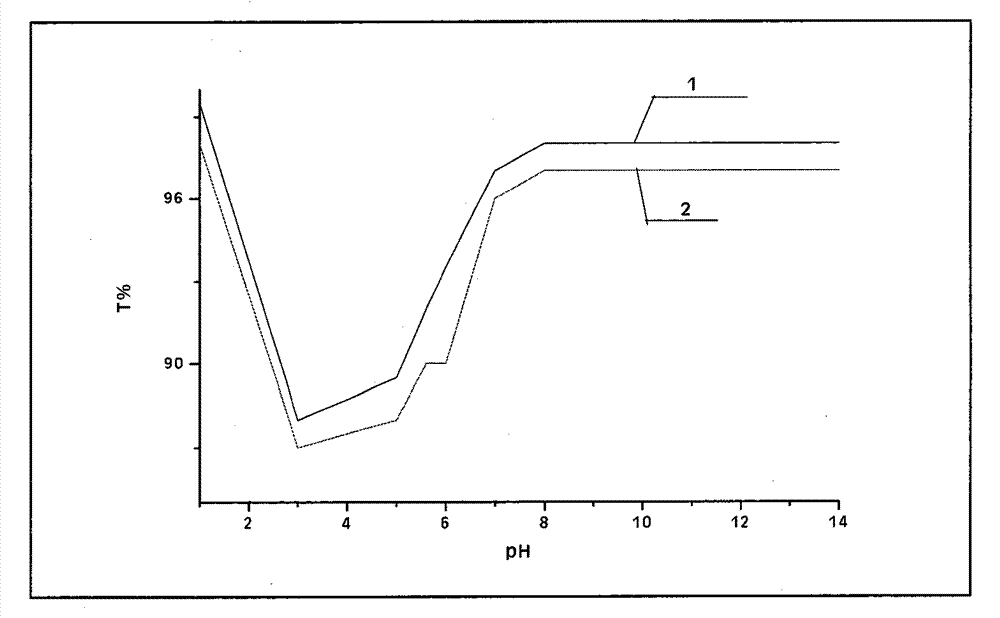

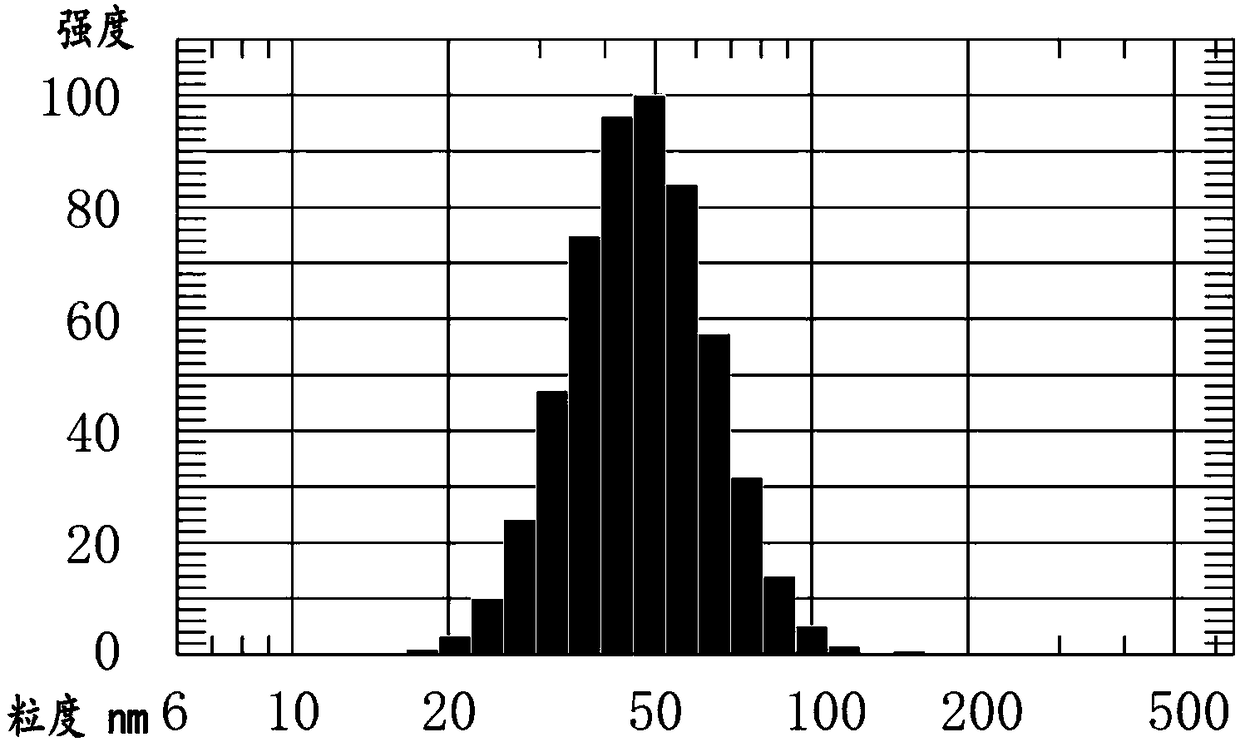

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000021.png)