Preparation method of indium tin sulfide visible-light-induced photocatalyst and visible-light-induced catalytic performance application of indium tin sulfide visible-light-induced photocatalyst

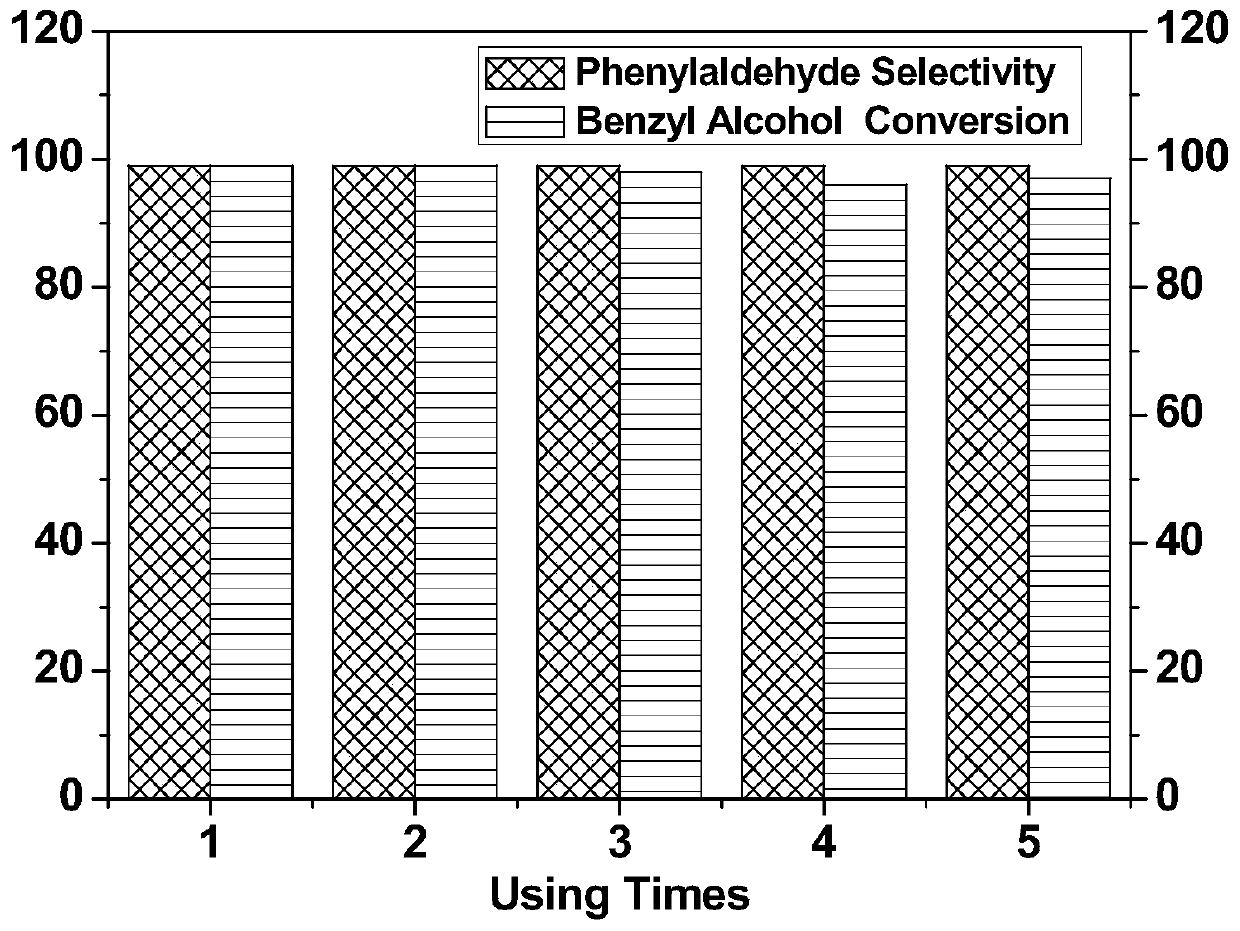

A technology of indium tin sulfide and visible light, which is applied in the direction of oxidative preparation of carbonyl compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory catalyst effects, achieve high peak intensity, simple process, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1.5mmol of tin tetrachloride pentahydrate and 4mmol of indium trichloride, then dissolve them in 60ml of deionized water, then weigh 8mmol of sulfur source thioacetamide and add them to the above-mentioned uniformly stirred aqueous solution, and adjust the pH value to 3. Continue to stir for 2h. The homogeneously stirred solution was transferred to a hydrothermal reactor, and reacted in an oven at 140° C. for 12 hours. Naturally cooled to room temperature, the obtained precipitate was washed three times with deionized water and absolute ethanol, and then vacuum-dried at 60° C. for 10 h to obtain an orange powder sample.

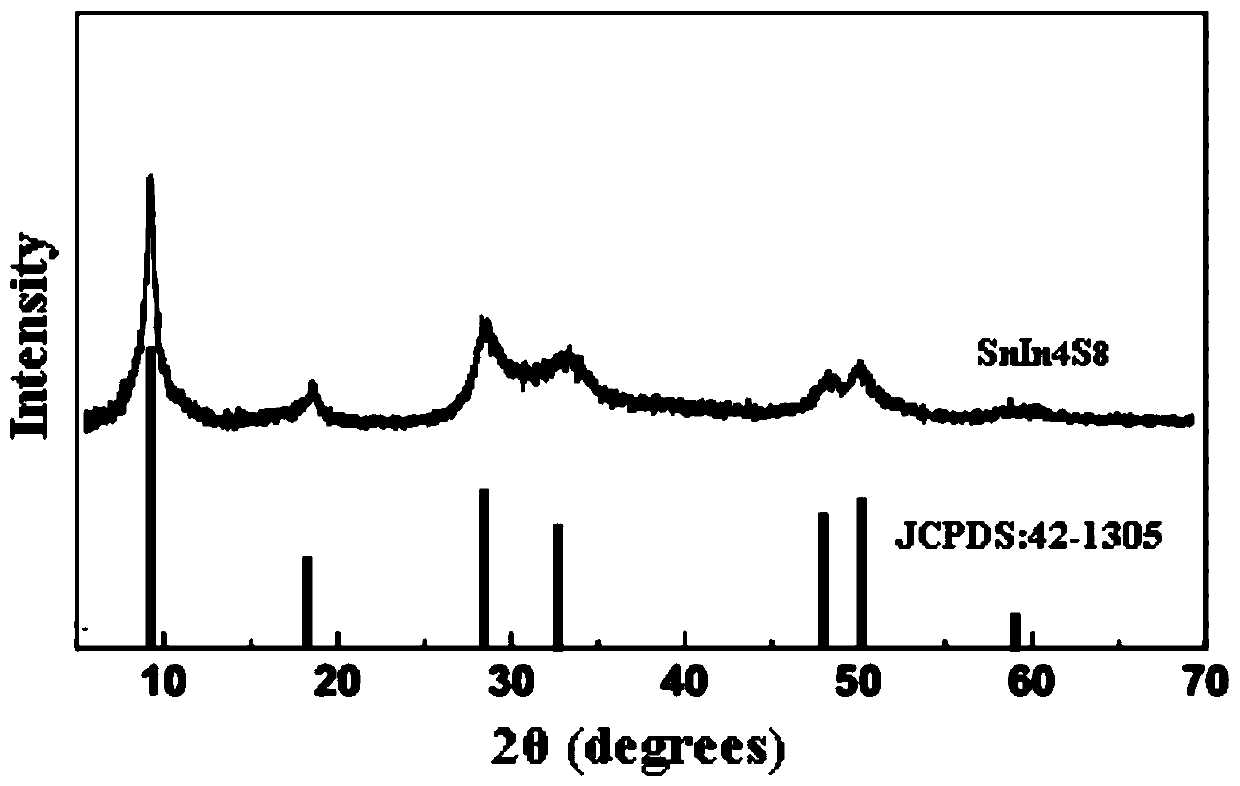

[0022] Embodiment 1 obtains indium tin sulfide (SnIn 4 S 8 ) photocatalyst, its XRD spectrum such as figure 1 Shown; SnIn 4 S 8 The diffraction characteristic peaks all appear, and are consistent with the JCPDS No.42-1305. card, indicating that a SnIn with a better crystal phase has been obtained 4 S 8 .

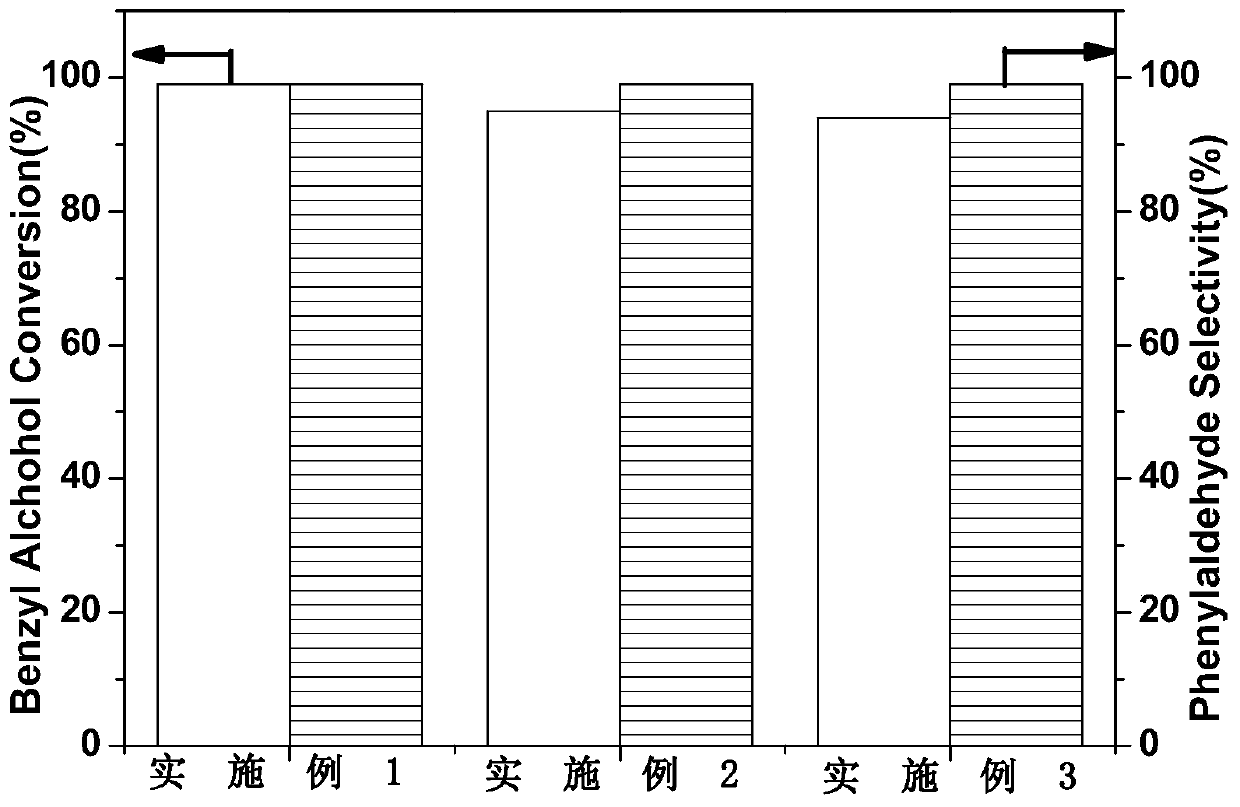

[0023] The SnIn of this embodime...

Embodiment 2

[0025] Weigh 1.5mmol of tin tetrachloride pentahydrate and 4mmol of indium trichloride, then dissolve them in 60ml of deionized water, then weigh 8mmol of thiourea and add it to the above-mentioned uniformly stirred aqueous solution, adjust the pH value to 5, and continue stirring 2h. The homogeneously stirred solution was transferred to a hydrothermal reaction kettle, and reacted in an oven at 160° C. for 10 h. Naturally cooled to room temperature, the obtained precipitate was washed four times with deionized water and absolute ethanol, and then vacuum-dried at 60° C. for 10 h to obtain an orange powder sample. Its XRD pattern is also consistent with figure 1 same.

[0026] Indium tin sulfide (SnIn) of the embodiment of the present invention 4 S 8 ) carried out the experiment that benzyl alcohol is catalyzed oxidation to formaldehyde under visible light, the result is as follows figure 2 Shown: the selectivity of benzaldehyde in reaction 10h is 99%, and the conversion r...

Embodiment 3

[0028] Weigh 1.5mmol of tin tetrachloride pentahydrate and 4mmol of indium trichloride, then dissolve them in 60ml of deionized water, then weigh 8mmol of L-cysteine and add them to the above-mentioned uniformly stirred aqueous solution, and adjust the pH value to 3. Continue to stir for 2h. The homogeneously stirred solution above was transferred to a hydrothermal reactor, and reacted in an oven at 180° C. for 10 h. Naturally cooled to room temperature, the obtained precipitate was washed three times with deionized water and absolute ethanol, and then vacuum-dried at 60° C. for 10 h to obtain an orange powder sample. Its XRD pattern is also consistent with figure 1 same.

[0029] The SnIn of the embodiment of the present invention 4 S 8 Carried out the experiment that benzyl alcohol is catalyzed oxidation to benzaldehyde under visible light, the result is as follows figure 2 Shown: the selectivity of benzaldehyde in reaction 10h is 99%, and the conversion rate of benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com