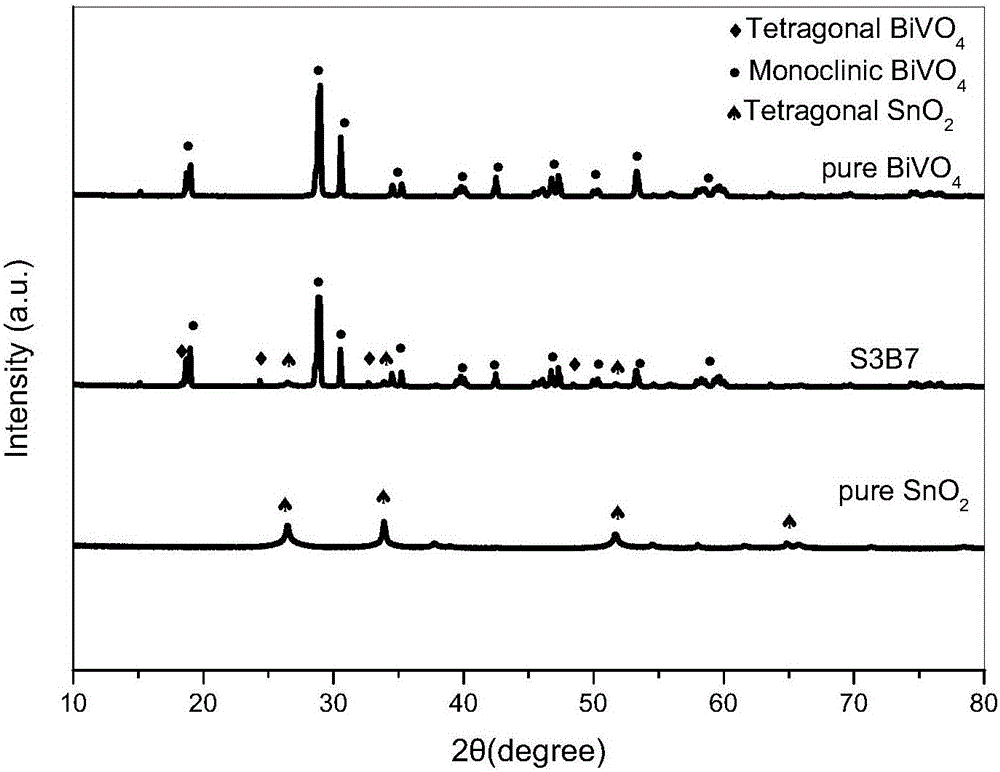

Pucherite-stannic oxide complex photocatalyst as well as preparation method and application thereof

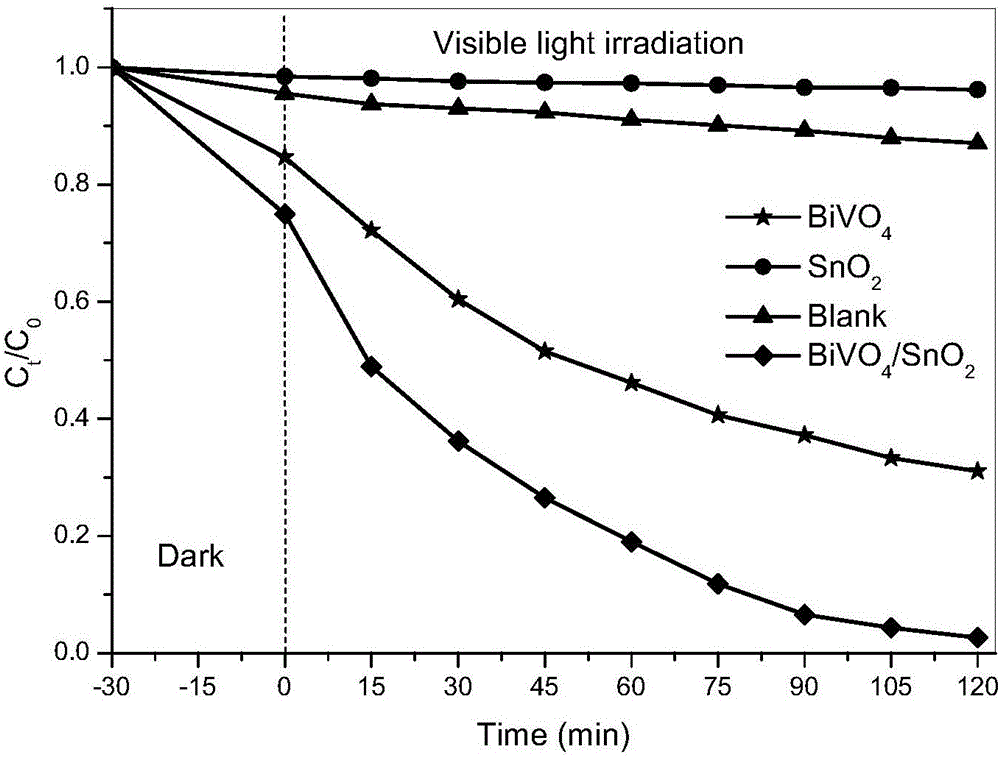

A composite light and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Difficult to separate, easy recombination of electrons and holes, etc., to achieve the effects of separation, large specific surface area, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under normal temperature and pressure, weigh 3.39g of Bi(NO 3 ) 3 ·5H 2 O and 1.05 g of SnCl 4 .5H 2 O powder in beaker A, add 20mL of nitric acid with a concentration of 4M, stir well to obtain a clear solution; and weigh 0.82g of NH 4 VO 3 In beaker B, add 20mL of NaOH with a concentration of 4M, and stir well to obtain a clear solution; then, under rapid stirring, add solution A to solution B dropwise to obtain a bright yellow solution, add NaOH with a concentration of 1M solution, adjust the pH value to 10, and ultrasonically vibrate for 30 minutes, transfer the bright yellow solution to a 100 mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150° C. for 24 hours. After cooling to room temperature, the product was washed several times with deionized water, and placed in an oven at 60°C for 24 hours. After cooling to room temperature, the obtained powder was finely ground with an agate mortar to obtain 2.54 g of bismuth vanadate-tin oxide ...

Embodiment 2

[0029] Under normal temperature and pressure, weigh 3.41g of Bi(NO 3 ) 3 ·5H 2 O and 1.06 g of SnCl 4 .5H 2 O powder in beaker A, add 20mL of nitric acid with a concentration of 4M, stir well to obtain a clear solution; and weigh 0.83g of NH 4 VO 3 In beaker B, add 20mL of NaOH with a concentration of 4M, and stir well to obtain a clear solution; then, under rapid stirring, add solution A to solution B dropwise to obtain a bright yellow solution, add NaOH with a concentration of 1M solution, adjust the pH value to 10, and ultrasonically vibrate for 30 minutes, transfer the bright yellow solution to a 100 mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150° C. for 24 hours. After cooling to room temperature, the product was washed several times with deionized water, and placed in an oven at 60°C for 24 hours. After cooling to room temperature, the obtained powder was finely ground with an agate mortar to obtain 2.41 g of bismuth vanadate-tin oxide ...

Embodiment 3

[0031] Under normal temperature and pressure, weigh 6.79g of Bi(NO 3 ) 3 ·5H 2 O and 2.11 g of SnCl 4 .5H 2 O powder in beaker A, add 20mL of nitric acid with a concentration of 4M, stir well to obtain a clear solution; and weigh 1.65g of NH 4 VO 3 In beaker B, add 20mL of NaOH with a concentration of 4M, stir well to obtain a clear solution; then, under rapid stirring, add solution A to solution B drop by drop to obtain a bright yellow solution, add NaOH with a concentration of 1M solution, adjust the pH value to 10, and ultrasonically vibrate for 30 minutes, transfer the bright yellow solution to a 100 mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150° C. for 24 hours. After cooling to room temperature, the product was washed several times with deionized water, and placed in an oven at 60°C for 24 hours. After cooling to room temperature, the obtained powder was finely ground with an agate mortar to obtain 4.98 g of bismuth vanadate-tin oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com