Octahedral metal oxide composite material and preparation and application thereof

A composite material and octahedral technology, which is applied in the field of metal oxide composite materials and their preparation and application, can solve the problems of low yield, complicated operation and high cost, and achieve the effects of high yield, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

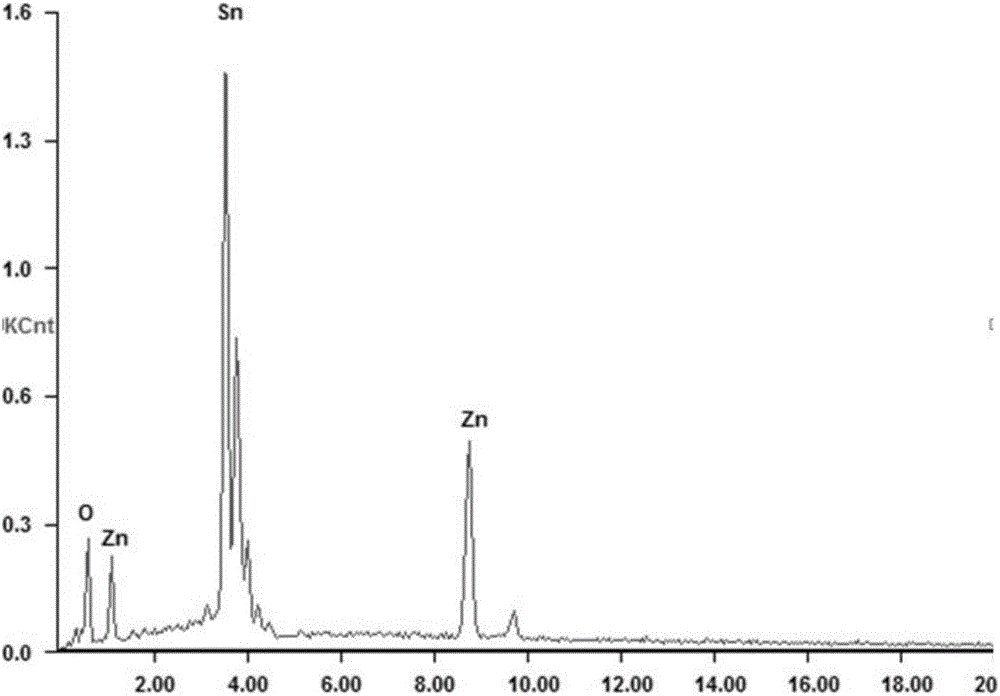

[0031] Preparation of Zn 2 SnO 4 / SnO 2 Octahedron, the size of the prepared octahedron is about 1.25 μm, and the reaction temperature is 20°C, which specifically includes the following steps:

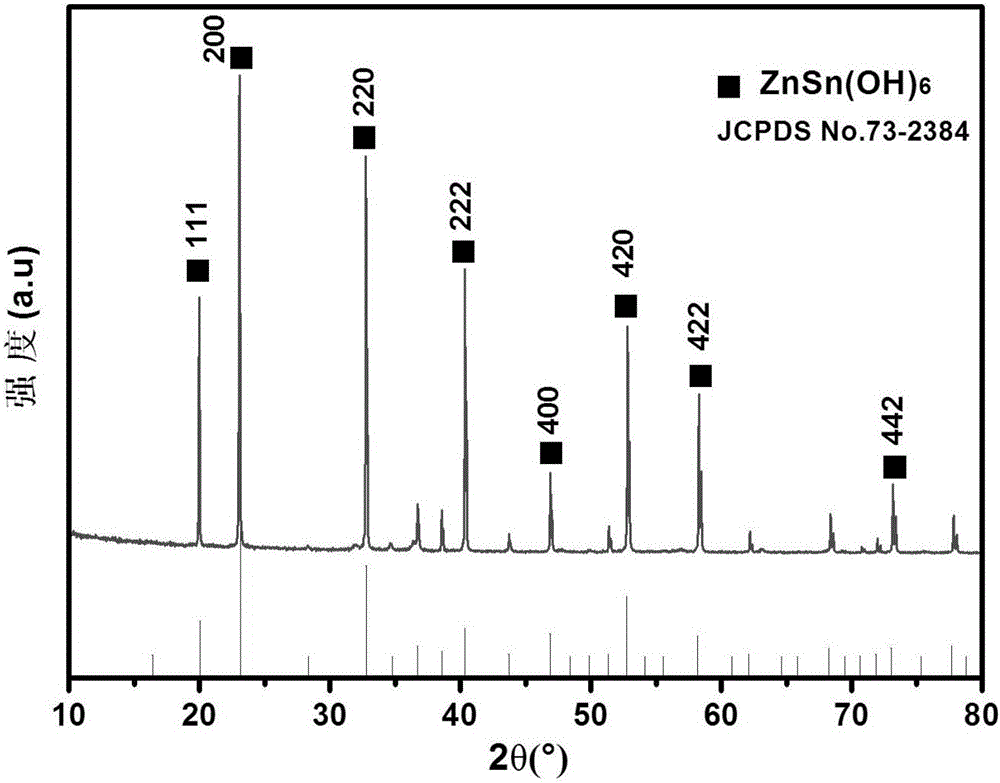

[0032] 12.5mL, 0.5mol / LZnAc 2 2H 2 The mixed aqueous solution of O and 0.5mol / L citric acid was vigorously stirred at room temperature, and 12.5mL, 0.5mol / LSnCl 4 ·5H 2 O aqueous solution, 25mL, 3.75mol / L NaOH solution, maintain the reaction temperature at 20°C, and stir vigorously for 5h. Immediately after the reaction, centrifugal separation was carried out, and then centrifugal washing was carried out with deionized water and ethanol, and the obtained precipitate was dried in a drying oven at 80°C for 24 hours to obtain ZnSn(OH) 6 octahedron.

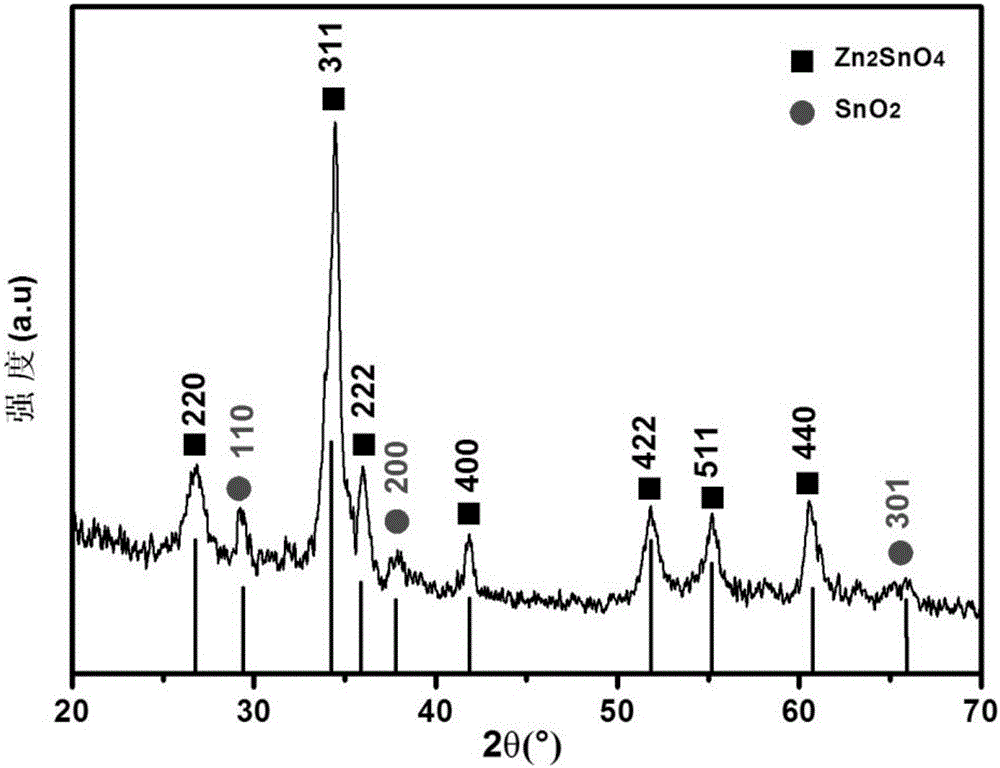

[0033] Then put the obtained white solid powder in the crucible, then heat up from room temperature to 600 °C in the temperature-programmed muffle furnace at a rate of 2 °C / min, keep it at a constant temperature for 2 hours, and take i...

Embodiment 2

[0037] Preparation of Zn 2 SnO 4 / SnO 2 Octahedron, the size of the prepared octahedron is about 3 μm, and the reaction temperature is 40°C, which specifically includes the following steps:

[0038] 12.5mL, 0.5mol / LZnAc 2 2H 2 The mixed aqueous solution of O and 0.5mol / L citric acid was vigorously stirred at room temperature, and 12.5mL, 0.5mol / LSnCl 4 ·5H 2 O aqueous solution, 25mL, 3.75mol / L NaOH solution, maintain the reaction temperature at 40°C, and stir vigorously for 5h. Immediately after the reaction was completed, it was collected by centrifugation, and then washed with deionized water and ethanol, and the obtained precipitate was dried in a drying oven at 80°C for 24 hours to obtain ZnSn(OH) 6 octahedron. For the shape and size of the product, see Figure 4 (40°C), after measurement, the single side length of the product is about 3 μm. Then put the obtained white solid powder in the crucible, then heat up from room temperature to 600 °C in the temperature-pr...

Embodiment 3

[0041] Preparation of Zn 2 SnO 4 / SnO 2 Octahedron, the size of the prepared octahedron is about 4 μm, and the reaction temperature is 60°C, which specifically includes the following steps:

[0042] 12.5mL, 0.5mol / LZnAc 2 2H 2 The mixed aqueous solution of O and 0.5mol / L citric acid was vigorously stirred at room temperature, and 12.5mL, 0.5mol / LSnCl 4 ·5H 2 O aqueous solution, 25mL, 3.75mol / L NaOH solution, maintain the reaction temperature at 60°C, and stir vigorously for 5h. Immediately after the reaction was completed, it was collected by centrifugation, and then washed with deionized water and ethanol, and the obtained precipitate was dried in a drying oven at 80°C for 24 hours to obtain ZnSn(OH) 6 octahedron. For the shape and size of the product, see Figure 4 (60°C), after measurement, the single side length of the product is about 4 μm. Then put the obtained white solid powder in the crucible, then heat up from room temperature to 600 °C in the temperature-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com