Efficient energy-saving novel nanometer material electrothermal film

A nano-electrothermal film and nano-material technology, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problem of many restrictions on working temperature and working voltage, the combination of electrothermal film and substrate is not very good, and the production of electrothermal film Complicated technological process and other issues, to achieve the effect of cheap raw materials, simple manufacturing process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

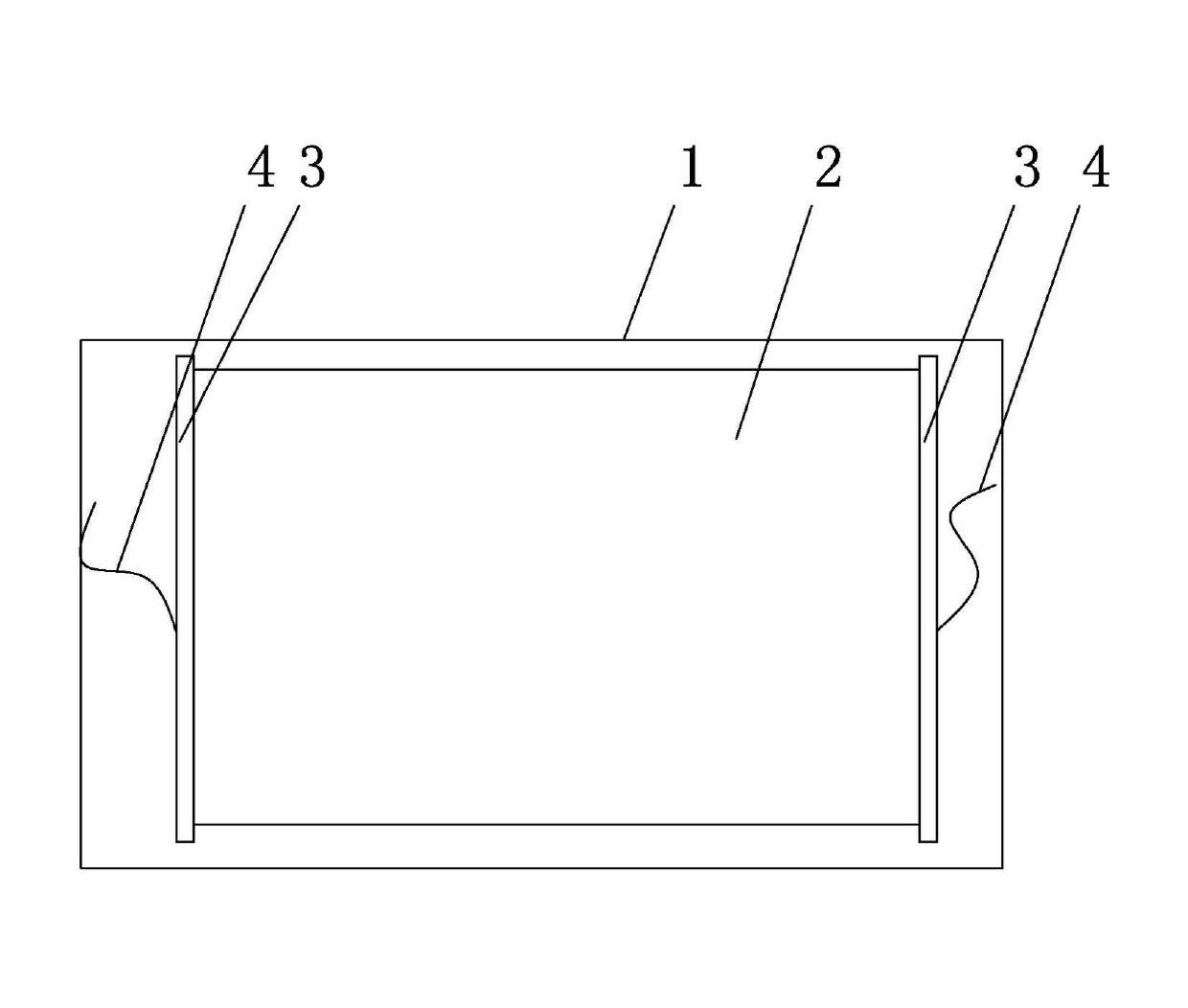

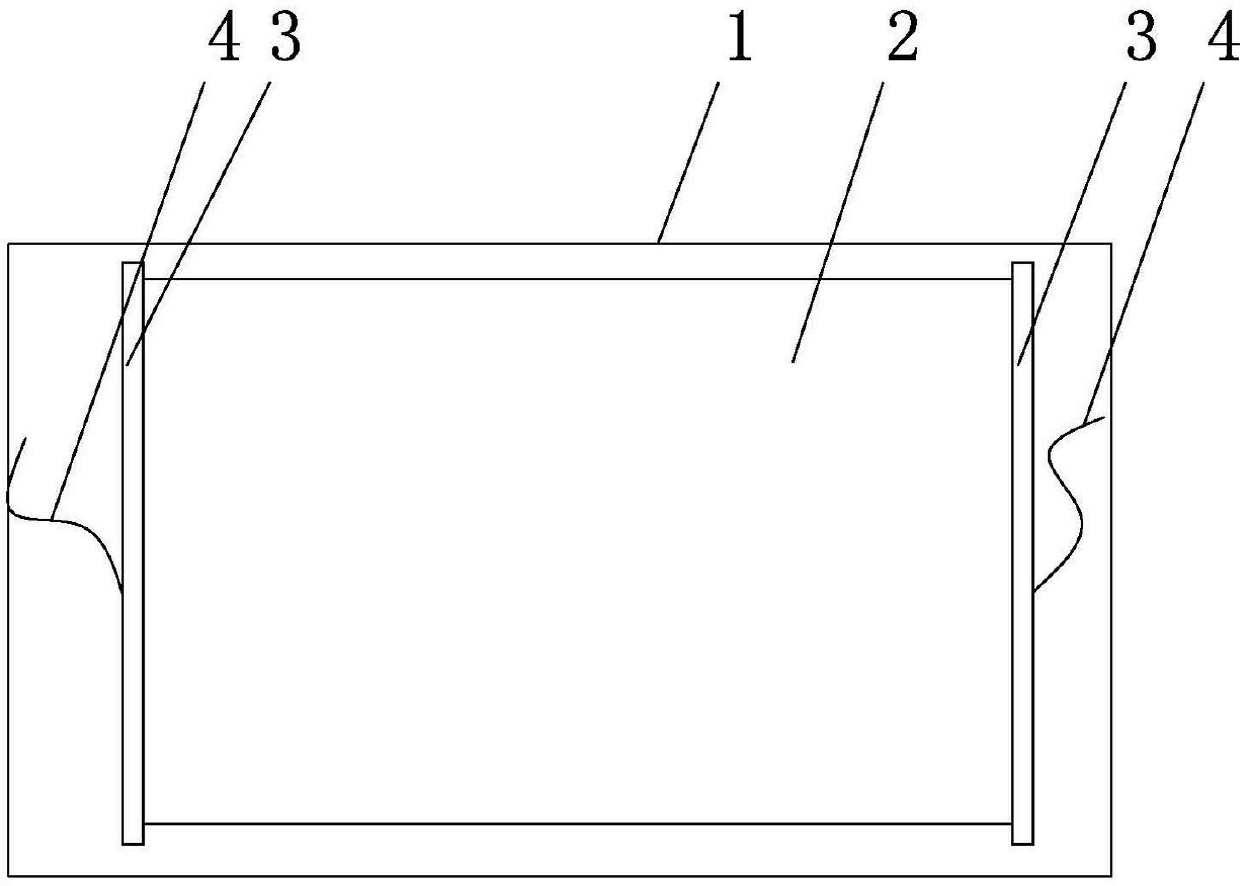

[0029] The first embodiment of the present invention is as follows, as figure 1 Shown:

[0030] (1) According to the mass percentage of each component, take tin tetrachloride 25, titanium tetrachloride 5, nickel tetrachloride 5, iron oxide 20, sodium chloride 2, tin dioxide 10, hydrochloric acid 8, glycerol 5. Put the ionized water 20 into a high-speed mixing and heating machine to mix and heat to 50°C, stir evenly to dissolve all the solid raw materials, and obtain the electric heating membrane external treatment solution after filtration;

[0031] (2) Using PVD technology to deposit the nano electrothermal film treatment solution on the substrate 1 under the condition of vacuum value of 95.0×10-2-100.0×10-2Pa, the obtained deposition product is the nano electrothermal film semi-finished product;

[0032] The raw materials of the invention are purcha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com