Preparation method for improving grain size and density of CZTS film

A copper-zinc-tin-sulfur, dense technology, applied in the field of optoelectronic materials and new energy materials, can solve the problems of easy volatilization and loss of S and Sn, difficulty in preparing high-density, large-grain thin film materials, phase separation, etc., and achieve cost Low cost, avoid volatilization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

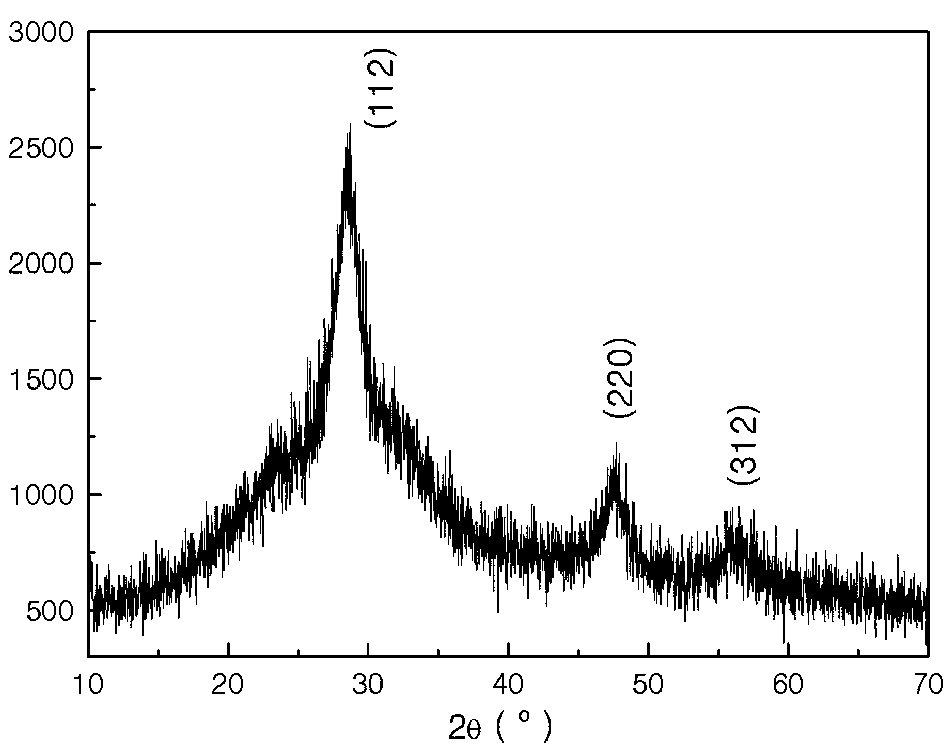

[0023] Dissolve 10 ml each of copper acetate, zinc acetate, and stannous chloride with concentrations of 0.8 mol / L, 0.4 mol / L, and 0.4 mol / L in 30 ml of ethylene glycol methyl ether and 3 ml of ethanolamine solution. At 45°C, stir until completely dissolved, then add 10 ml of 2 mol / L thiourea solution and stir evenly to obtain a copper-zinc-tin-sulfur solution. This solution was dropped on a soda-lime glass substrate placed on a spin coater, and spin-coated at 800 rpm for 6 s, and then at 2500 rpm for 20 s. After spin coating, it was dried at 300 °C for 5 min. The spin-coating and drying process was repeated five times to obtain a copper-zinc-tin-sulfur thin film with a thickness of 2 μm. figure 1 It is the X-ray diffraction pattern of the copper-zinc-tin-sulfur thin film obtained after spin coating, and its diffraction peaks are all copper-zinc-tin-sulfur phases, and no second phase related to impurities is found, indicating that the obtained copper-zinc-tin-sulfur film has ...

Embodiment 2

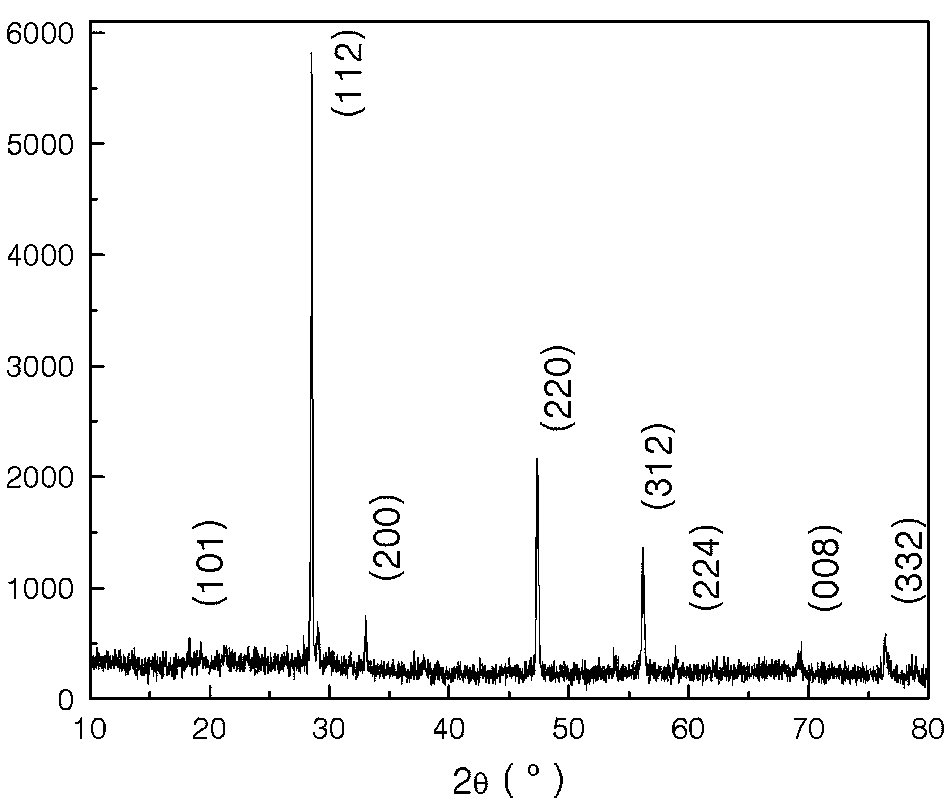

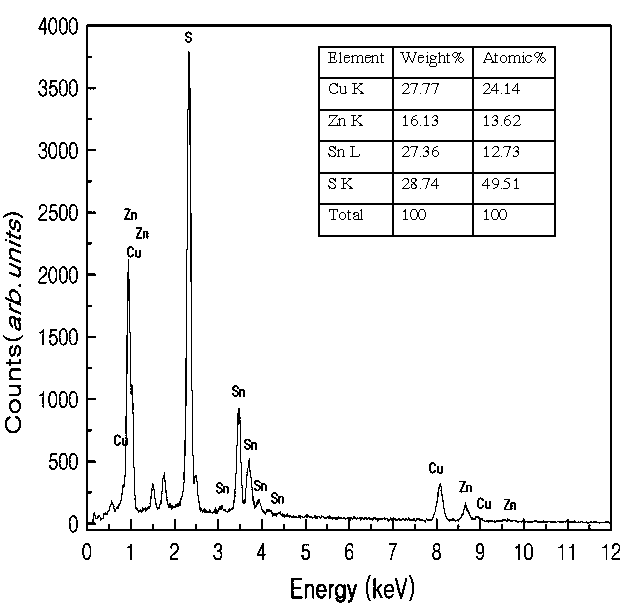

[0025] The copper-zinc-tin-sulfur film sample prepared by the spin coating method was placed in a quartz tube, and the appearance size of the quartz tube was Φ 10mm×150mm, wall thickness 1mm. Put 500 mg of sulfur powder (purity 99%) into the quartz tube, and vacuum the quartz tube through a mechanical pump. After the vacuum degree of the quartz tube drops to 0.1 atm, use an oxyacetylene flame to melt and seal the open end of the quartz tube. Put the sealed quartz tube horizontally into the muffle furnace for constant temperature heat treatment at 700 °C for 1 h. After cooling with the furnace, take out the sample for testing and analysis. figure 2 It is the X-ray diffraction pattern of the film sample prepared by vulcanizing the sealed quartz tube at a high temperature of 700 °C, image 3 It is the EDX spectrum of the film sample, which shows that Cu:Zn:Sn:S in the film is about 2:1:1:4. The experimental data show that the sample is Cu with a single tetragonal phase struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com