Synthetic method and application of rare-earth-doped SnO2/TS-1 nano photocatalytic material

A catalytic material and rare earth doping technology, applied in the field of photocatalytic materials, can solve problems such as few researches, and achieve the effects of good repeatability, good reusability, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

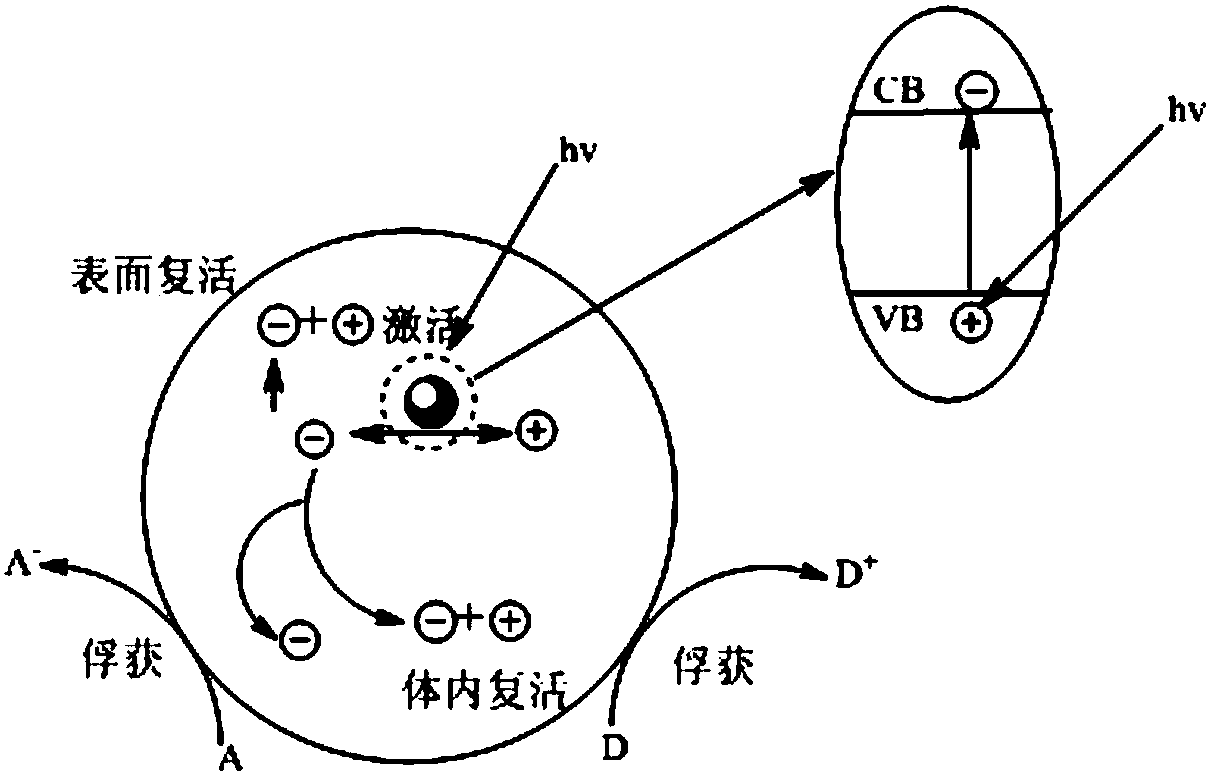

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

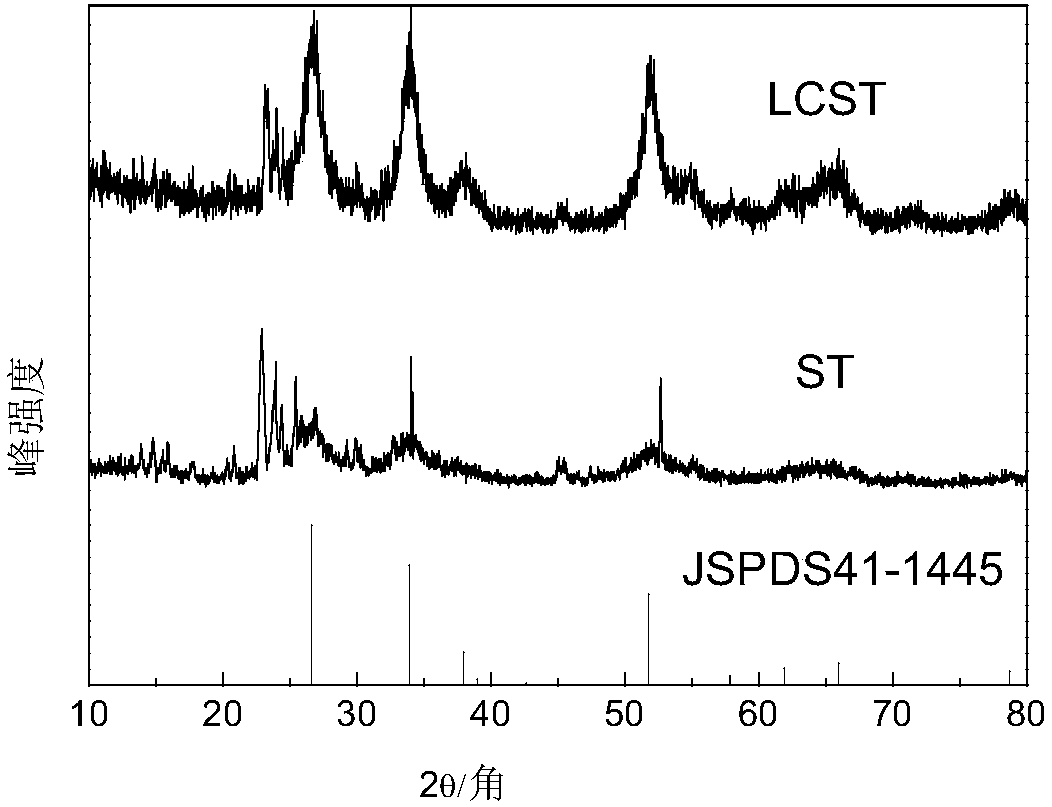

[0038] The preparation of embodiment 1 photocatalyst LST

[0039] Weigh 3.0gSnCl 4 ·5H 2 O, add 20ml distilled water, 0.06g lanthanum nitrate and 0.1ml concentrated HCl, then add a certain amount of ammonia water, adjust the pH of the solution to 7.0–8.0, obtain a white sol after ultrasonic dispersion for 2 hours; add 3.0g titanium silicon molecular sieve to the sol TS-1, stirred for 2 hours, left to age for 15 hours, then washed and dried to obtain the precursor, the precursor was placed in a muffle furnace, and fired at 500 ° C for 2 hours to obtain lanthanum-doped supported nano-SnO 2 , named LST.

Embodiment 2

[0040] The preparation of embodiment 2 photocatalyst CST

[0041] Weigh 3.0gSnCl 4 ·5H 2 O, add 20ml distilled water, 0.06g cerium nitrate and 0.1ml concentrated HCl, then add a certain amount of ammonia water, adjust the pH of the solution to 7.0–8.0, obtain a white sol after ultrasonic dispersion for 2 hours; add 3.0g titanium silicon molecular sieve to the sol TS-1, stirred for 2 hours, left to age for 15 hours, then washed and dried to obtain the precursor, the precursor was placed in a muffle furnace, and fired at 500°C for 2 hours to obtain rare earth metal cerium-doped supported nano-SnO 2, named CST.

Embodiment 3

[0042] The preparation of embodiment 3 photocatalyst LCST

[0043] Weigh 3.0gSnCl 4 ·5H 2 O, add 20ml of distilled water, 0.06g of lanthanum nitrate and 0.1ml of concentrated HCl, stir until the solution is clear, then add a certain amount of ammonia water, adjust the pH of the solution to 7.0–8.0, obtain a white sol after ultrasonic dispersion for 2 hours; add 3.0g of titanium-silicon molecular sieve TS-1 and 0.03g of cerium nitrate were stirred for 2 hours, then left to age for 15 hours, then washed and dried to obtain a precursor, which was placed in a muffle furnace and calcined at 500°C for 2 hours to obtain Lanthanum and Ce-doped supported nano-SnO 2 , named LCST.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com