Preparation method of perylenetetracarboxylic diimide modified polyimide polymer material

A technology of perylene tetracarboximide and perylene tetracarboximide is applied in the field of preparation of polyimide polymer materials, which can solve the problem of decreased energy storage density, increased conductivity loss, and inability to adapt to the working voltage environment and other problems, to achieve the effect of easy large-scale industrial production and uniform dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

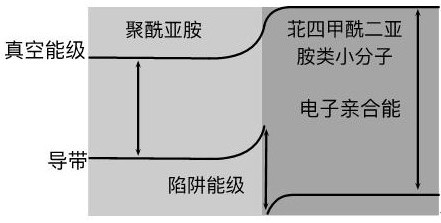

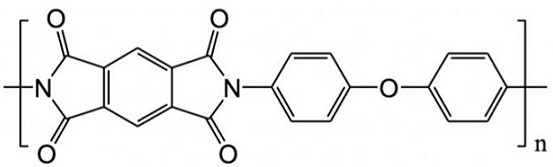

[0034] In terms of suppressing the loss of conductance, especially in the case of high electric field, the density of local states in the polymer medium is very large, and the electrons injected into the polymer are bound in different local state energy levels. The conduction process is mainly due to the electron It is caused by migration between localized states, that is, electrons jump from one localized state to another by means of hopping conductance. After the introduction of perylenetetracarboximide small molecules, because of its strong electron affinity, deep traps can be formed inside the polymer material, such as figure 1 As shown, these deep traps can effectively hinder the migration process of electrons in the localized state, thereby suppressing the loss caused by the internal hopping conductance of the polymer medium under high temperature and high electric field.

Embodiment 2

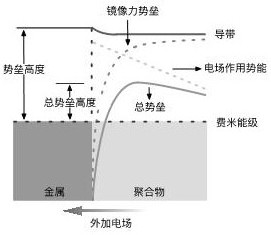

[0036] The Schottky barrier curve of the contact interface between the metal electrode and the polymer medium is as follows: figure 2 shown. Electrons emitted from a point in the metal electrode will induce a corresponding positive charge in the electrode, and the electron will be affected by the image force generated by the electric field of the induced positive charge. The barrier height that electrons need to cross from the metal electrode to the polymer medium is the work function of the metal minus the electron affinity of the polymer medium. Under the action of an external electric field, electrons will overcome the image force and inject from the metal electrode into the polymer medium, and the action of the electric field reduces the height of the potential barrier that electron injection needs to overcome during this process. This patent uses semiconductor small molecules to build an electron adsorption layer at the electrode-polymer interface, and the electron adso...

Embodiment 3

[0038] In terms of improving the breakdown field strength, small molecules of perylenetetracarboximide can capture high-energy electrons, decompose themselves, be excited and ionized to form free radicals, and weaken the impact of electrons on polymer molecular chains under strong electric fields, thereby Increase the breakdown field strength of polymer materials. The Weber distribution of breakdown field strength of polyimide polymer materials modified by perylenetetracarboximide derivatives at 150ºC is as follows: Figure 7 As shown, its characteristic breakdown field strength is about 491 MV / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com