A kind of leaching method and leaching system of valuable metals in waste lithium battery cathode material

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of leaching method and leaching system of valuable metals in the positive electrode materials of waste lithium batteries, can solve the problems of environmental pollution of the treatment method, achieve high-efficiency leaching, high leaching rate, and good industrial application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: the leaching of lithium, nickel, cobalt, manganese in waste and old ternary lithium ion battery

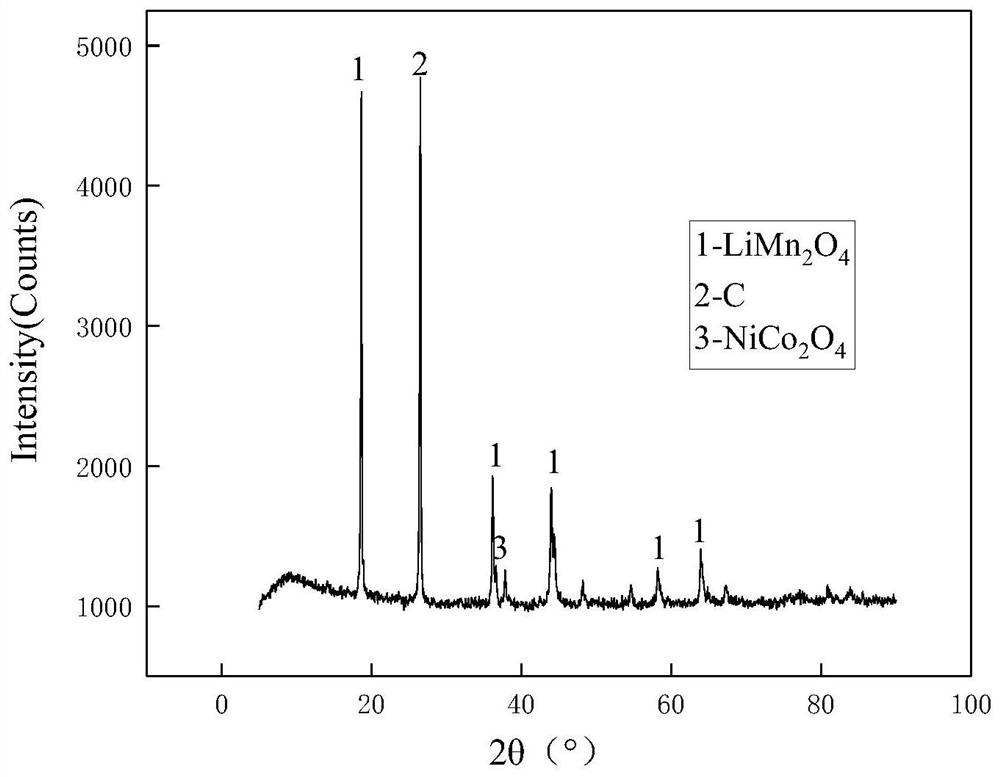

[0072] After the waste ternary lithium ions are pretreated by discharging and crushing, the positive electrode material is separated. The Li content in the positive electrode material is 3.00%, the Mn content is 32.29%, the Co content is 2.38%, and the Ni content is 3.59%, mainly LiMn 2 o 4 and NiCo 2 o 4 form, such as figure 1 shown.

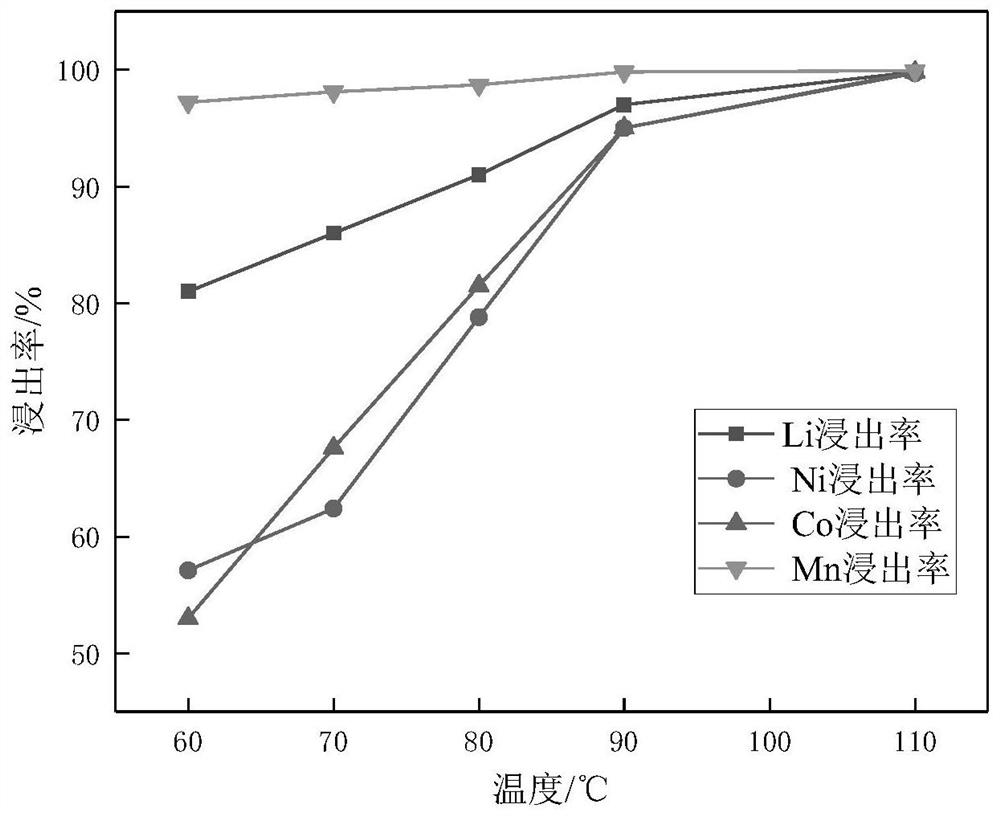

[0073] Experimental conditions: the concentration of malonic acid is 1.5mol / L, the solid-to-liquid ratio is 40g / L, the mass of glucose is 0.8 times the mass of the positive electrode powder, and the reaction time is 40min.

[0074] Configure 250mL aqueous solution of malonic acid and glucose in a beaker, add 10g of positive electrode powder, and change the leaching temperature conditions (the leaching temperature is set to 60°C, 70°C, 80°C, 90°C, 100°C, 110°C respectively), according to The leaching reaction was carried o...

Embodiment 2

[0075] Embodiment 2: the leaching of lithium, nickel, cobalt, manganese in waste and old ternary lithium ion battery

[0076] After the waste ternary lithium ions are pretreated by discharging and crushing, the positive electrode material is separated. The Li content in the positive electrode material is 3.00%, the Mn content is 32.29%, the Co content is 2.38%, and the Ni content is 3.59%.

[0077] Experimental conditions: the concentration of malonic acid is 1.5mol / L, the mass of glucose is 0.8 times the mass of the positive electrode powder, the leaching reaction time is 40min, and the leaching temperature is 110°C.

[0078] Configure 250mL aqueous solution of malonic acid and glucose in a beaker, add 10g of positive electrode powder, by changing the solid-liquid ratio (the solid-liquid ratio is set to 20g / L, 30g / L, 40g / L, 50g / L, 60g / L respectively ) conditions, and carry out the leaching reaction according to the experimental conditions, the leaching rate results of lithiu...

Embodiment 3

[0079] Embodiment 3: the leaching of lithium, nickel, cobalt, manganese in waste and old ternary lithium ion battery

[0080] After the waste ternary lithium ions are pretreated by discharging and crushing, the positive electrode material is separated. The Li content in the positive electrode material is 3.50%, the Mn content is 6.10%, the Co content is 16.12%, and the Ni content is 7.08%, mainly LiCoO 2 , Li 0.65 mn 1.08 o 2 and exist in the form, such as Figure 4 shown.

[0081] Experimental conditions: the solid-to-liquid ratio is 20g / L, the mass of glucose is 0.7 times the mass of the positive electrode powder, the leaching reaction time is 40min, and the leaching reaction temperature is 110 degrees Celsius.

[0082] Configure 250mL aqueous solution of malonic acid and glucose in a beaker, add 5g of positive electrode powder, by changing the concentration of malonic acid (the concentration of malonic acid is set to 1.20mol / L, 1.25mol / L, 1.30mol / L, 1.35mol / L, 1.40mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com