Chemical fiber dyeing process with ultra-low sewage discharge

A process and sewage technology, applied in the direction of dyeing, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of environmental pollution and high COD of sewage, and achieve the effects of low cost, water quality improvement and strong dispersion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

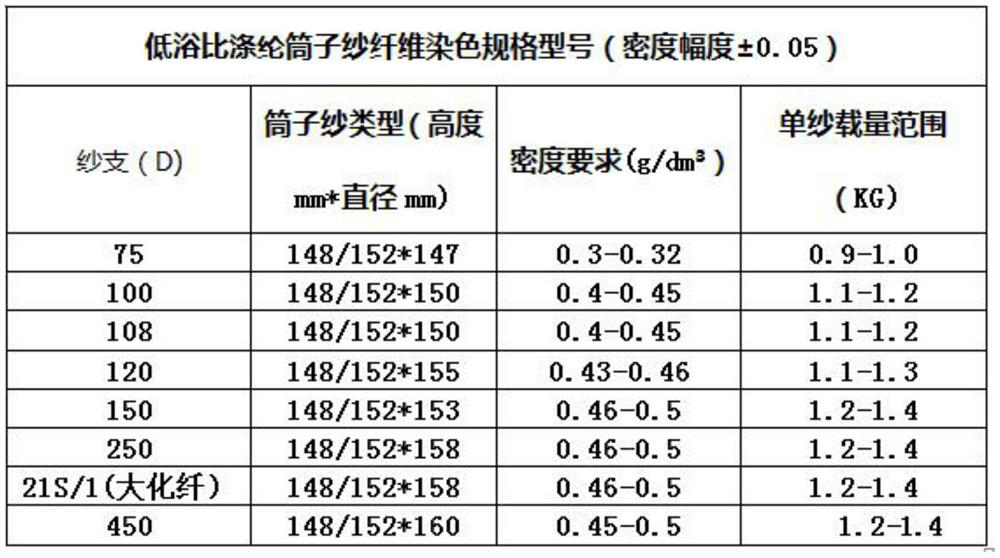

Image

Examples

Embodiment 1

[0031] A chemical fiber dyeing process with ultra-low discharge of sewage, comprising the following steps:

[0032]Step 1. Dyeing: adopt one-step-one-bath dyeing process, the specific operation is: add dispersant SQ-1091.0g / L, leveling agent YDL-320 2.5g / L, HAC 1.0g / L, dye OWF dosage at room temperature 0.5%, degreasing agent 1.5g / L, then add polyester cheese, the single yarn weight of polyester cheese is 1.2kg, and the density is 0.42g / cm 3 , the process bath ratio is 1:2.5, then heat up to 70°C, hold for 5 minutes, continue to heat up to 110°C, hold for 8 minutes, continue to heat up to 130°C, and hold for 45 minutes;

[0033] Step 2. Post-treatment: The light-colored post-treatment process is as follows: add 0.8g / L acetic acid or acidic additives to adjust the pH value to 7, wash with hot water for 5 minutes, and the temperature is 80°C;

[0034] Step 3. Sewage separation and treatment: the cooling water in the heating process is directly recycled into the non-pressure con...

Embodiment 2

[0036] A chemical fiber dyeing process with ultra-low discharge of sewage, comprising the following steps:

[0037] Step 1. Dyeing: adopt one-step-one-bath dyeing process, the specific operation is: add 1.5g / L dispersant SQ-109, 1.0g / L leveling agent YDL-320, 1.2g / L HAC, and OWF dye at room temperature 3%, degreaser 1g / L, then add polyester cheese, the single yarn weight of polyester cheese is 1.4kg, and the density is 0.46g / cm 3 , the process bath ratio is 1:3.0, then heat up to 65°C, hold for 8 minutes, continue to heat up to 115°C, hold for 10 minutes, continue to heat up to 135°C, and hold for 30 minutes;

[0038] Step 2. Post-processing: The post-processing process for medium and dark colors is: add 2.5g / L acetic acid or acidic additives to adjust the pH value to 5.5, keep warm at 90°C for 10 minutes, wash and drain;

[0039] Step 3. Sewage separation and treatment: the cooling water in the heating process is directly recycled into the non-pressure container in the dyein...

Embodiment 3

[0041] A chemical fiber dyeing process with ultra-low discharge of sewage, comprising the following steps:

[0042] Step 1. Dyeing: adopt one-step-one-bath dyeing process, the specific operation is: add dispersant SQ-109 2.0g / L, leveling agent YDL-320 1.2g / L, HAC 1.5g / L, dye OWF dosage at room temperature 7%, degreaser 1.3g / L, then add polyester cheese, the single yarn weight of polyester cheese is 1.3kg, and the density is 0.45g / cm 3 , the process bath ratio is 1:2.6, then heat up to 68°C, hold for 7 minutes, continue to heat up to 112°C, hold for 9 minutes, continue to heat up to 132°C, and hold for 40 minutes;

[0043] Step 2. Post-processing: The post-processing process for dark colors is: including reduction cleaning and hot water cleaning. The specific operation is: add 2g / L sodium hydroxide and 2g / L sodium hydroxide, keep warm at 80°C for 10 minutes, and add 0.8g / L soaping agent, keep warm at 70°C for 10 minutes, add 2.5g / L acetic acid or acidic additives to adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com