Preparation method of linseed oil and compound emulsion and high internal phase emulsion thereof

A high-internal-phase emulsion and compound technology, applied in the field of oil processing, can solve the problems of unstable emulsion system and easy to be affected by the environment, and achieve the effects of preventing demulsification, good dispersibility, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, preparation linseed oil emulsion and high internal phase emulsion

[0040] 1) Preparation of wall material and core material

[0041] Carrageenan and egg white protein are used as emulsified wall materials, and linseed oil is used as core materials;

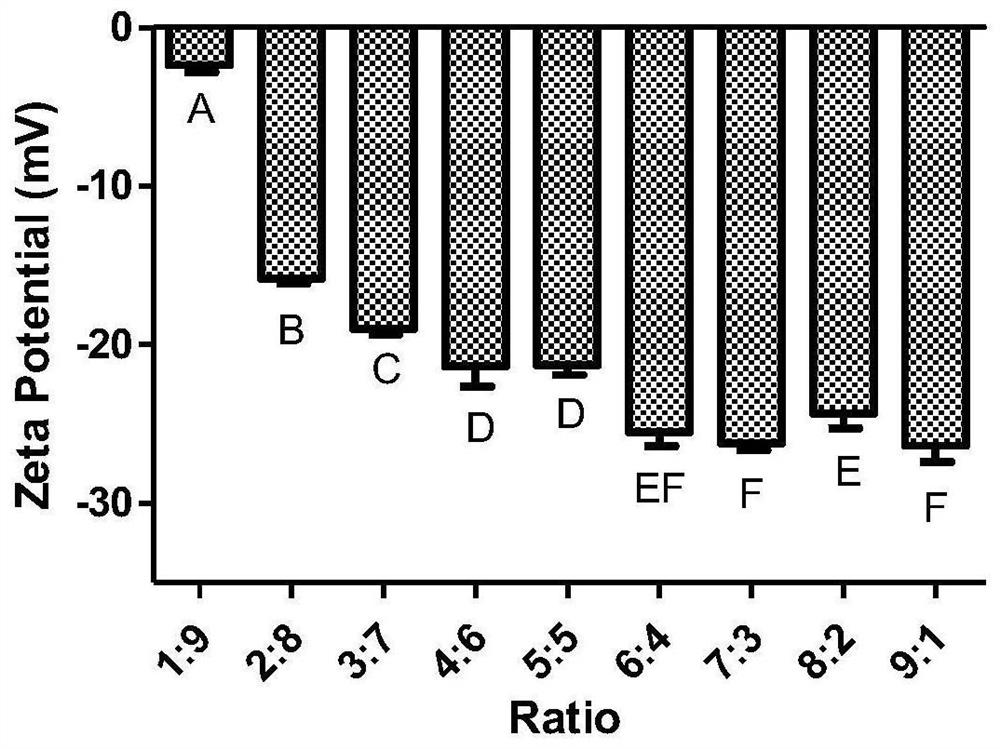

[0042] Prepare a carrageenan aqueous solution with a mass concentration of 0.6%, and the solution presents a negative charge;

[0043] An egg white protein aqueous solution with a mass concentration of 0.4% is prepared, and the solution presents a negative charge.

[0044] 2) Preparation of coarse emulsion

[0045] Take the 100mL carrageenan aqueous solution and 100mL egg white protein aqueous solution prepared in step 1) and add them to 100mL linseed oil (wherein the mass ratio of carrageenan to egg white protein is 6:4). Adopt high-speed shearing machine to obtain coarse emulsion after the mixture is sheared at a high speed of 10000rpm for 2min.

[0046] 3) Preparation of emulsion

[0047] A high-press...

Embodiment 2

[0055] Embodiment 2, preparation linseed oil emulsion and high internal phase emulsion

[0056] 1) Preparation of wall material and core material

[0057] Chondroitin sulfate and whey protein are used as emulsified wall materials, and linseed oil is used as core materials;

[0058] Prepare an aqueous solution of chondroitin sulfate with a mass concentration of 0.7%, and the solution is negatively charged;

[0059] A whey protein aqueous solution with a mass concentration of 0.3% is prepared, and the solution presents a negative charge.

[0060] 2) Preparation of coarse emulsion

[0061] Take the 100mL chondroitin sulfate aqueous solution and 100mL whey protein aqueous solution prepared in step 1), and add them to 100 mL linseed oil (wherein the mass ratio of chondroitin sulfate and whey protein is 7:3). Adopt high-speed shearing machine to obtain coarse emulsion after the mixture is sheared at a high speed of 15000rpm for 1.5min.

[0062] 3) Preparation of emulsion

[006...

Embodiment 3

[0071] Embodiment 3, preparation linseed oil emulsion and high internal phase emulsion

[0072] 1) Preparation of wall material and core material

[0073] Carrageenan and egg white protein are used as emulsified wall materials, and linseed oil is used as core materials;

[0074] Prepare a carrageenan aqueous solution with a mass concentration of 1.2%, and the solution presents a negative charge;

[0075] An egg white protein aqueous solution with a mass concentration of 0.8% is prepared, and the solution presents a negative charge.

[0076] 2) Preparation of coarse emulsion

[0077] Take the 100mL carrageenan aqueous solution and 100mL egg white protein aqueous solution prepared in step 1) and add them to 150mL linseed oil (wherein the mass ratio of carrageenan to egg white protein is 6:4). Adopt high-speed shearing machine to obtain coarse emulsion after the mixture is sheared at a high speed of 20000rpm for 1min.

[0078] 3) Preparation of emulsion

[0079] A high-press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap