Preparation method and application of magnetic composite nano material

A magnetic composite nanometer and magnetic nanoparticle technology, applied in chemical instruments and methods, silicon compounds, alkali metal compounds, etc., can solve the problems of high activity of magnetic nanoparticle surface groups, difficult to use directly, easy to oxidize, etc. Simple, low cost, improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

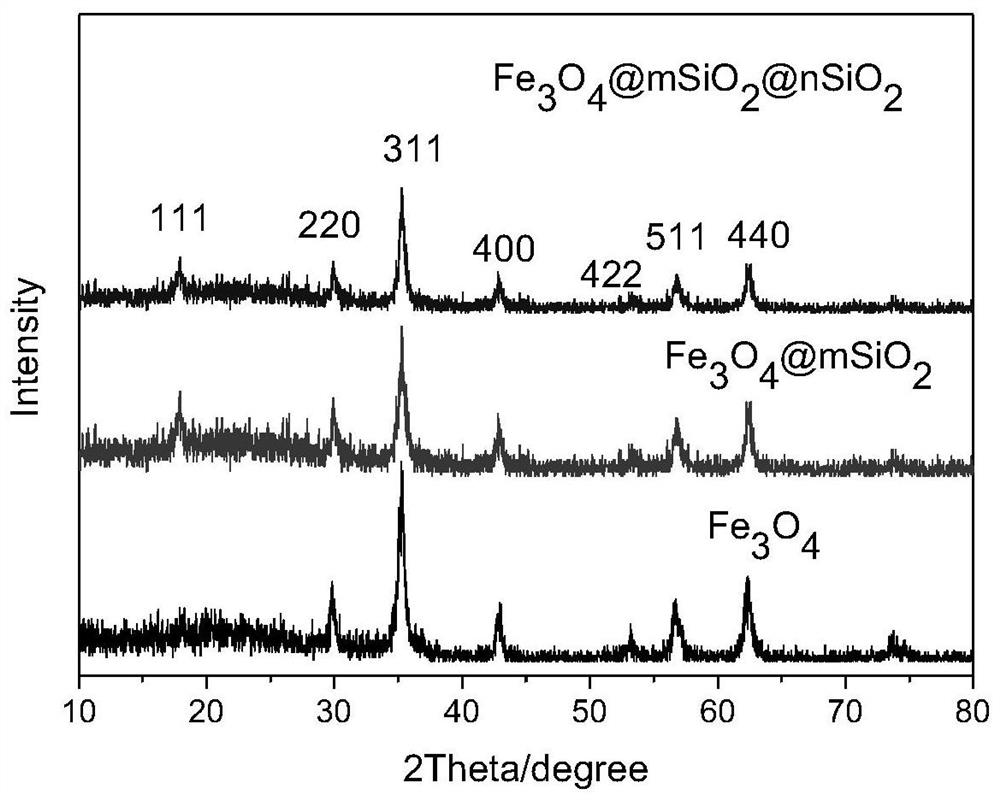

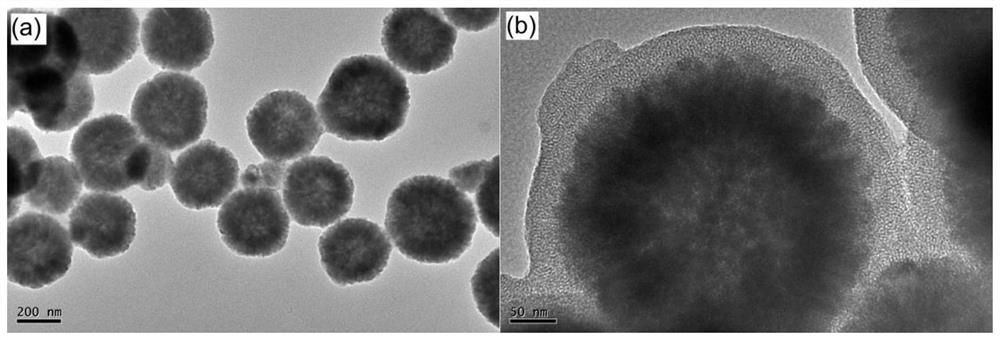

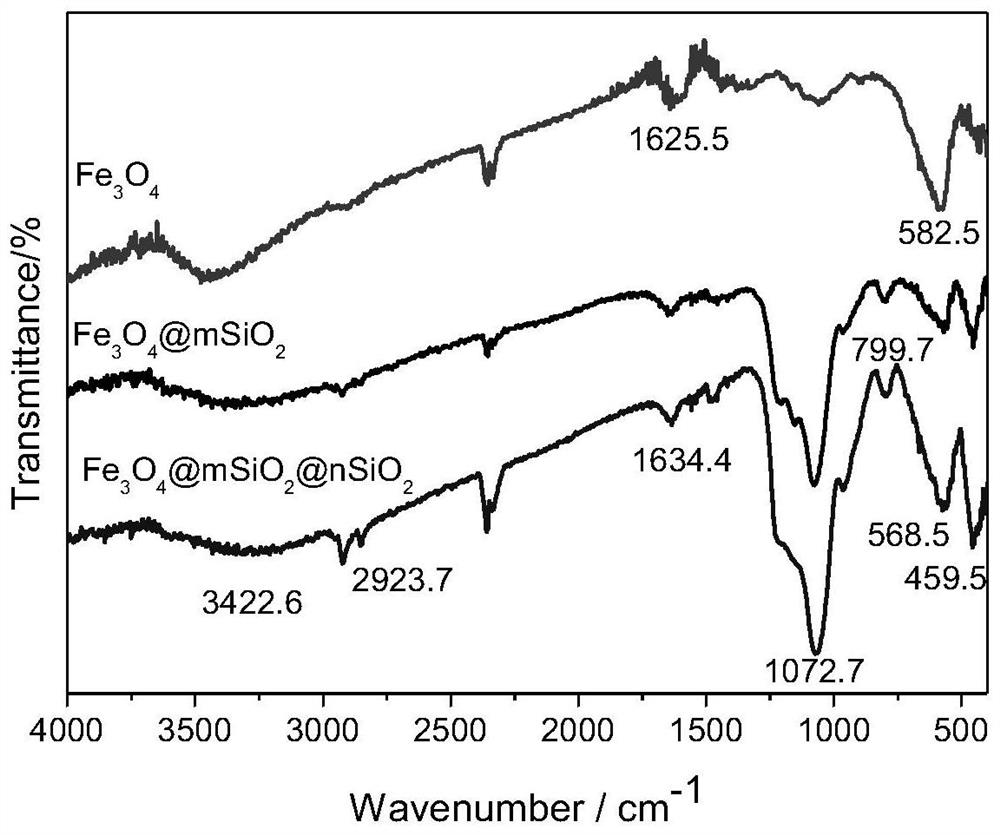

[0028] A preparation method of magnetic composite nanomaterials, comprising the following steps:

[0029]Step S101: Fe 3 o 4 Preparation of magnetic nanoparticles: 1.08 g of FeCl 3 ·6H 2 O was dissolved in 160 mL of ethylene glycol to prepare a 0.025 mol / L ferric chloride solution. Under magnetic stirring conditions, add 2.88 g of sodium acetate and 0.80 g of urea. After the solids were completely dissolved, pour the solution into a high-pressure reactor , tighten the lid of the kettle, and place it in a blast drying oven at 180°C for 12 hours, then take out the autoclave and cool it to room temperature, magnetically separate the product in the autoclave, and wash the product with absolute ethanol 3 times, wash the product twice with secondary water, then wash the product once with absolute ethanol, and finally put the washed product in a vacuum drying oven at 80°C for 15 hours to obtain Fe 3 o 4 Magnetic nanoparticles, stored for future use.

[0030] Step S102: Fe 3 o ...

specific Embodiment 2

[0034] A preparation method of magnetic composite nanomaterials, comprising the following steps:

[0035] Step S101: Fe 3 o 4 Preparation of magnetic nanoparticles: 1.06 g of FeCl 3 ·6H 2 O was dissolved in 160 mL of ethylene glycol to obtain a 0.025 mol / L ferric chloride solution. Under magnetic stirring, 2.89 g of sodium acetate and 0.82 g of polyethylene glycol-200 were added. After the solid was completely dissolved, the Pour the solution into the autoclave, tighten the lid of the autoclave, and place it in a blast drying oven at 250°C for 8 hours, then take out the autoclave and cool it to room temperature, and magnetically separate the product in the autoclave to obtain a solid Wash the product 5 times with absolute ethanol, wash the product 4 times with secondary water, and wash the product once with absolute ethanol, and finally put the washed product in a vacuum drying oven at 100°C for 12 hours to obtain Fe 3 o 4 Magnetic nanoparticles, stored for future use.

...

specific Embodiment 3

[0040] A preparation method of magnetic composite nanomaterials, comprising the following steps:

[0041] Step S101: Fe 3 o 4 Preparation of magnetic nanoparticles: 1.08 g of FeCl 3 ·6H 2 O was dissolved in 160 mL of ethylene glycol to obtain a 0.025 mol / L ferric chloride solution. Under magnetic stirring, 2.88 g of sodium acetate and 0.80 g of cinnamic acid were added. After the solids were completely dissolved, the solution was poured into a high-pressure In the reaction kettle, tighten the lid of the kettle, put it in a blast drying oven at 200°C for 8 hours, then take out the high-pressure reaction kettle, and cool it to room temperature, magnetically separate the products in the reaction kettle, and use absolute ethanol to obtain the solid Wash the product 3 times, wash the product 3 times with secondary water, wash the product 1 time with absolute ethanol, and finally put the washed product in a vacuum drying oven at 100°C for 12 hours to obtain Fe 3 o 4 Magnetic na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com