High-transmittance low-emissivity coated glass and preparation process thereof

A low-radiation coating and preparation process technology, applied in the field of high-transmittance low-radiation coated glass and its preparation process, can solve the problems of wear and corrosion, poor wear resistance and corrosion resistance, etc., so as to increase the service life and improve the heat insulation. Performance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

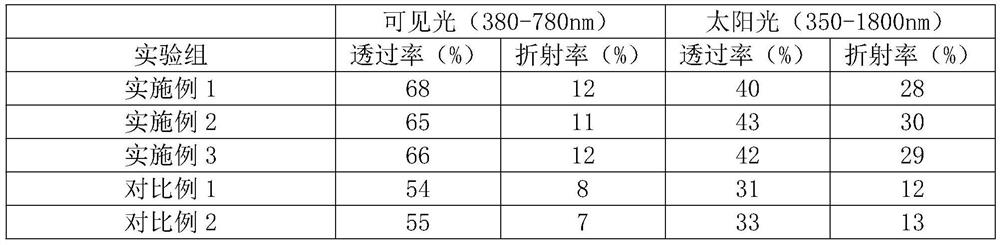

Examples

Embodiment 1

[0034] A high-transmittance low-radiation coated glass includes a glass substrate, a first dielectric film, a functional film, and an outer dielectric film stacked from bottom to top.

[0035] The first dielectric film is composed of a tin oxide layer and a titanium dioxide layer.

[0036] The outer dielectric film is composed of a zinc oxide layer and a silicon aluminum alloy layer.

[0037] The thickness of the first dielectric film is 0.3 μm, and the thickness of the outer dielectric film is 0.5 μm.

[0038] The raw materials of each component of the functional film are as follows, in parts by weight, including 40 parts of polystyrene, 10 parts of phenol, 5 parts of 4-chloronitrobenzene, 2 parts of anti-ultraviolet and anti-aging agent, 5 parts of binder, 2 parts of plasticizer, 0.5 parts of dispersant.

[0039] The anti-ultraviolet anti-aging agent is various mixtures of p-nitroaniline, N-phenyl-α-naphthylamine, and 4-methyl-6-tert-butylphenol.

[0040] The binder is an...

Embodiment 2

[0054] A high-transmittance low-radiation coated glass includes a glass substrate, a first dielectric film, a functional film, and an outer dielectric film stacked from bottom to top.

[0055] The first dielectric film is composed of a tin oxide layer and a titanium dioxide layer.

[0056] The outer dielectric film is composed of a zinc oxide layer and a silicon aluminum alloy layer.

[0057] The thickness of the first dielectric film is 0.4 μm, and the thickness of the outer dielectric film is 0.6 μm.

[0058] The raw materials of each component of the functional film are as follows, in parts by weight, including 45 parts of polystyrene, 13 parts of phenol, 6 parts of 4-chloronitrobenzene, 3 parts of anti-ultraviolet and anti-aging agent, 6 parts of binder, 3 parts of plasticizer, 0.7 parts of dispersant.

[0059] The anti-ultraviolet anti-aging agent is various mixtures of p-nitroaniline, N-phenyl-α-naphthylamine, and 4-methyl-6-tert-butylphenol.

[0060] The binder is an...

Embodiment 3

[0074] A high-transmittance low-radiation coated glass includes a glass substrate, a first dielectric film, a functional film, and an outer dielectric film stacked from bottom to top.

[0075] The first dielectric film is composed of a tin oxide layer and a titanium dioxide layer.

[0076] The outer dielectric film is composed of a zinc oxide layer and a silicon aluminum alloy layer.

[0077] The thickness of the first dielectric film is 0.5 μm, and the thickness of the outer dielectric film is 0.7 μm.

[0078] The raw materials of each component of the functional film are as follows, in parts by weight, including 50 parts of polystyrene, 15 parts of phenol, 7 parts of 4-chloronitrobenzene, 4 parts of anti-ultraviolet and anti-aging agent, 7 parts of binder, 4 parts plasticizer, 1 part dispersant.

[0079] The anti-ultraviolet anti-aging agent is various mixtures of p-nitroaniline, N-phenyl-α-naphthylamine, and 4-methyl-6-tert-butylphenol.

[0080] The binder is any one or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com