Carbon fiber-based SiO2 aerogel foam cement and preparation method thereof

A technology of foamed cement and airgel, which is applied to ceramic products, other household appliances, applications, etc., and can solve the problems of low strength of foamed cement wall insulation materials, large thermal conductivity, and micro-cracks in the bubble wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

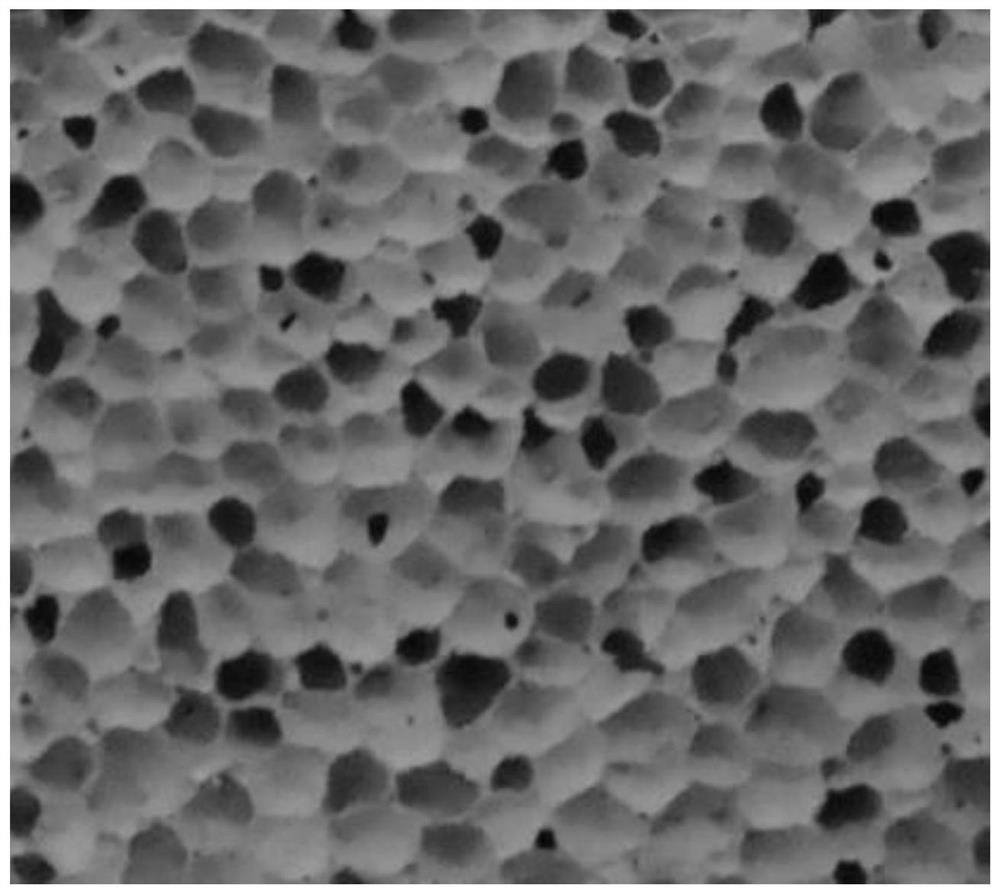

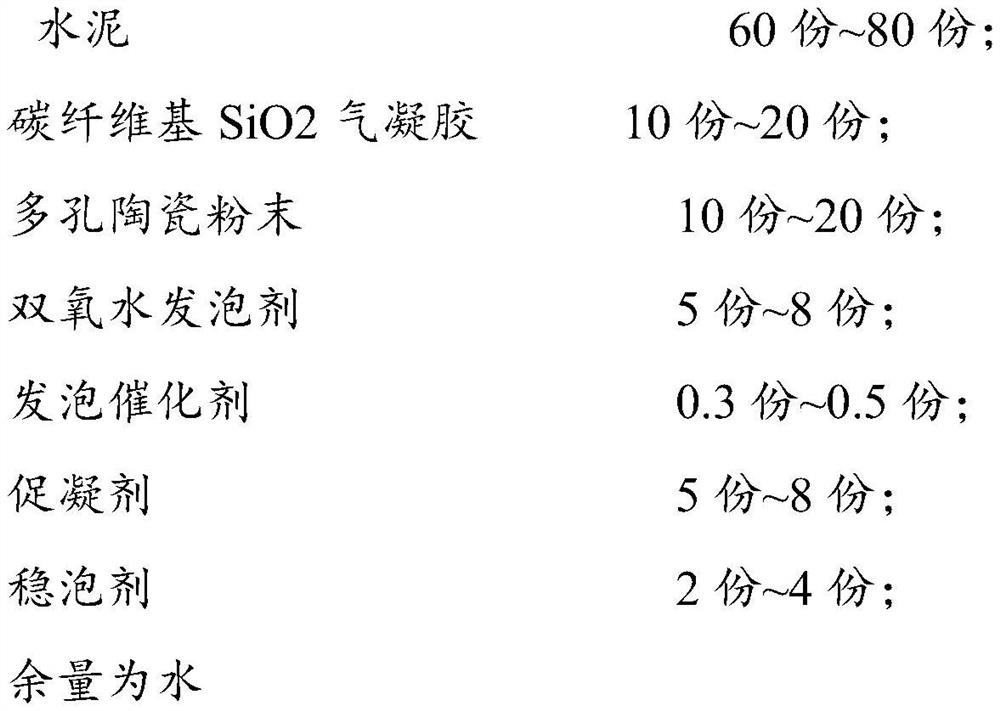

[0035] Example 1, this embodiment provides a carbon fiber-based SiO2 airgel foaming cement

[0036] Gas gel is also known as dry gel. When the gel is removed, the liquid content in the gel is much less than that of the solid content, or the medium filled in the spatial mesh structure of the gel is a gas, the outer surface is solid, which is a dry gel, also Airgel.

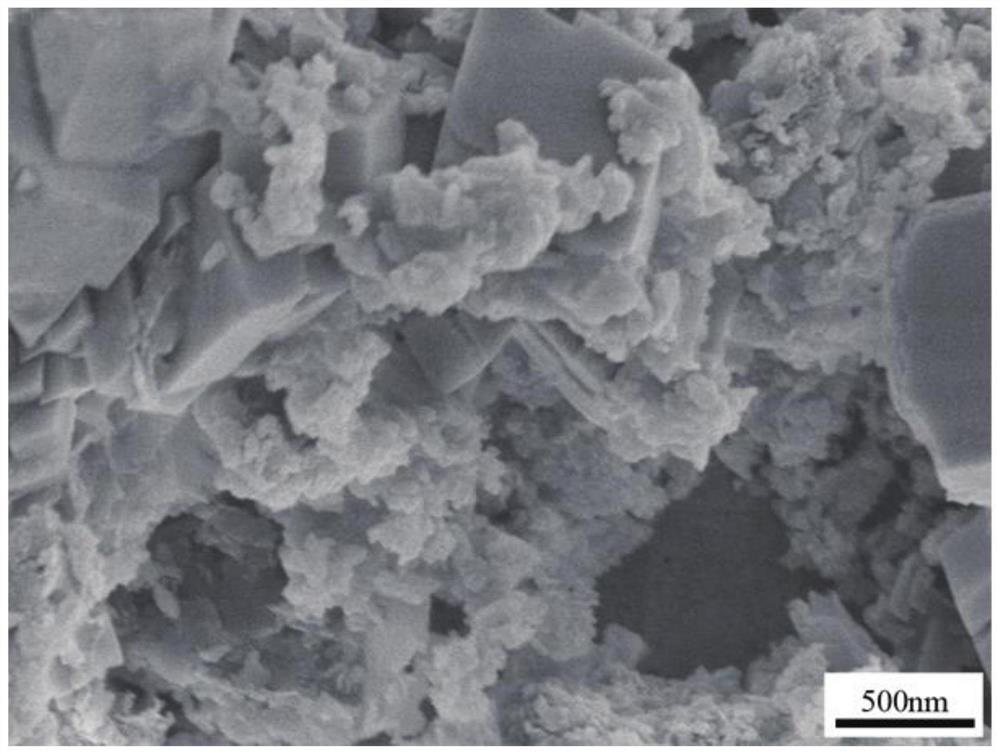

[0037] In the present embodiment, the carbon fiber-based SiO2 airgel is first prepared, and the carbon fibers are added to the dimethyl sulfoxide to maintain the heating to uniformly dispersed, stir well, and the addition of carbon fibers is the weight of the formed airgel. 20%, in this example, the main purpose of adding the carbon fiber to the airgel is to increase the strength of the entire airgel, the dimethyl sulfoxide as the solvent produced by the airgel.

[0038] After mixing is mixed, the methyltrimethoxysilane and the oxalic acid were stirred at 30 ° C for 30 min. The addition of oxalic acid can obtain a more...

Embodiment 2

[0054] Example 2, this embodiment provides a carbon fiber-based SiO2 airgel foaming cement

[0055] Compared with the first embodiment, it is mainly in the addition of the feedstock, in the present embodiment, 20 parts of cement; 20 parts of carbon fiber-based SiO2 airgel; 20 parts of porous ceramic powder; 8 parts of hydrogen oxide foaming agent; oxidation 0.5 parts of manganese foaming catalyst; 8 servic concentrates of sodium carbonate and triethanolamine, wherein the mass ratio of sodium carbonate and triethanolamine is 10: 1; steady calcium stearate modified by nano-ink layer technology. 4 parts of the bubble agent; the margin is water, the cement is a silicate cement. The porous ceramic powder is a particle size of the existing discarded porous ceramic into a particle size of 325. This is the common particle size of the existing silicate cement. Of course, it can be larger, up to 180 mesh. . The balance is water, and it is added according to the proportion of water ash than ...

Embodiment 3

[0057] Example 3, this embodiment provides a carbon fiber-based SiO2 airgel foaming cement

[0058] Compared with the first embodiment, it is mainly in the addition of the feedstock, in the present embodiment, 15 parts of cement; carbon fiber SiO2 airgel; porous ceramic powder 15 parts; 6 hydrogen foaming agents; oxidation 0.4 parts of manganese foaming catalyst; 6 parts of the complex of sodium carbonate and triethanolamine, wherein the mass ratio of sodium carbonate and triethanolamine is 10: 1; the steady calcium carbonate modified by nano-ink layer technology. 3 parts of the bubble agent; the margin is water, the cement is a silicate cement. The porous ceramic powder is a particle size of the existing discarded porous ceramic into a particle size of 325. This is the common particle size of the existing silicate cement. Of course, it can be larger, up to 180 mesh. . The balance is water, and it is added according to the proportion of water ash than 0.46.

[0059] After testing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com