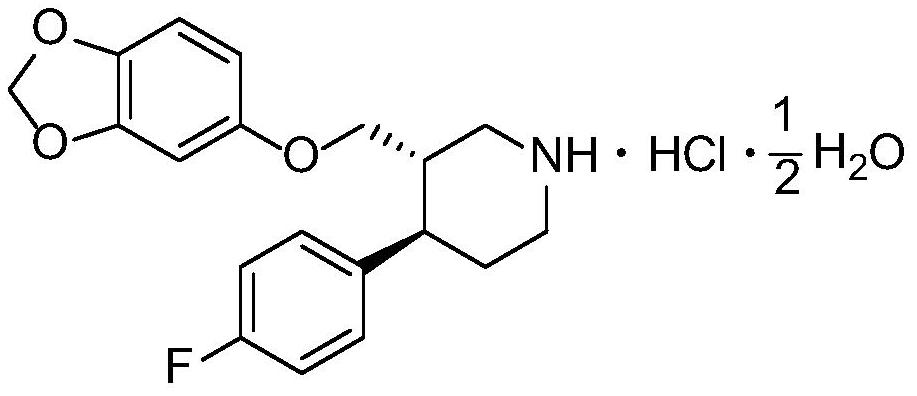

Continuous preparation method of paroxetine hydrochloride

A technology of paroxetine hydrochloride and paroxol, which is applied in the field of medicine, can solve the problems of being unsuitable for continuous chemical industrial production, unfavorable environmental protection, and high price, and achieves the control of the generation of toxic impurities, which is beneficial to environmental protection and has fewer purification steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

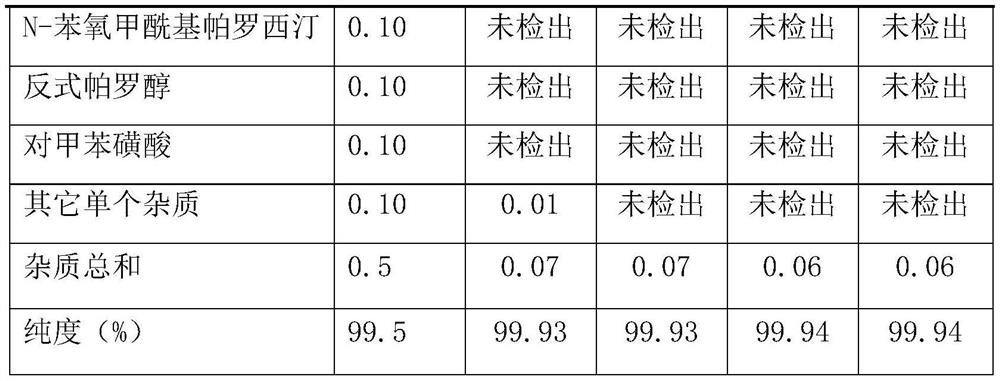

Embodiment 1

[0032] (1) Preparation of Paroxetine Hydrochloride Crude Product

[0033] 1) Add 500kg of toluene, 50kg of trans-parol, and 60kg of p-toluenesulfonyl chloride into a 1000L glass-lined reactor, stir and cool down to -5~5°C, and add 32kg of triethylamine to control the temperature at -5~5°C. Raise the temperature to 25°C and react for 4 hours. TLC monitors that the reaction is complete, and the reaction solution is transferred to a 1000L stainless steel reactor for later use;

[0034] 2) Add 100 kg of 20% aqueous sodium hydroxide solution to the above-mentioned stainless steel reaction kettle, stir for 1 hour, let stand, separate liquids, leave the organic phase in the stainless steel reaction kettle, add 3 kg of tetrabutylammonium bromide, sesame seeds to the stainless steel reaction kettle 34kg of phenol, stirred evenly, added 150kg of 40% sodium hydroxide aqueous solution, heated to reflux for 2 hours, TLC monitored the reaction to be complete, cooled to room temperature, all...

Embodiment 2

[0040] 1) Preparation of Paroxetine Hydrochloride Crude Product

[0041] 1) Add 550kg of xylene, 50kg of trans-parol, and 51.2kg of p-toluenesulfonyl chloride into a 1000L glass-lined reactor, stir and cool down to -5~5°C, and add 16.4kg of ethanolamine to control the temperature at -5~5°C , the temperature was raised to -5°C for 8 hours, the reaction was monitored by TLC, and the reaction solution was transferred to a 1000L stainless steel reactor for later use;

[0042] 2) Add 100kg of 20% aqueous sodium hydroxide solution in the above-mentioned stainless steel reaction kettle, stir for 1 hour, leave standstill, separate liquids, the organic phase stays in the stainless steel reaction kettle, add tetrabutylammonium chloride 1.9kg, Sesamol 30.9kg, stir evenly, add 112kg of 40% sodium hydroxide aqueous solution, heat up to reflux reaction for 2 hours, TLC monitors that the reaction is complete, cool down to room temperature, let stand, separate liquids, and transfer the organic ...

Embodiment 3

[0048] (1) Preparation of Paroxetine Hydrochloride Crude Product

[0049] 1) Add 500kg of cyclohexane, 50kg of trans-parol, and 64.0kg of p-toluenesulfonyl chloride into a 1000L titanium reactor, stir and cool down to -5~5°C, control the temperature at -5~5°C and add sodium bicarbonate 33.9kg, heated up to 30°C for 3 hours, TLC monitored the reaction was complete;

[0050] 2) Add 100 kg of 20% aqueous sodium hydroxide solution to the above-mentioned titanium reactor, stir for 1 hour, let stand and separate liquids, leave the organic phase in the titanium reactor, and add 7.2 kg of tetrabutylammonium bromide to the titanium reactor 1. Sesamol 46.4kg, stir evenly, add 448kg of 40% aqueous sodium hydroxide solution, heat up to reflux reaction for 2 hours, TLC monitors that the reaction is complete, cool down to room temperature, leave standstill, separate liquid, and the organic phase is retained in the titanium reactor;

[0051] 3) Heat the titanium reactor containing the organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com