Method for preparing super-hydrophobic paper through laser printing

A super-hydrophobic paper, a certain amount of technology, applied in papermaking, paper, paper coatings, etc., can solve the problems of failure, insufficient environmental protection, complicated preparation methods of super-hydrophobic paper, etc., and achieves the reduction of free energy, good moisture resistance, and self-healing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

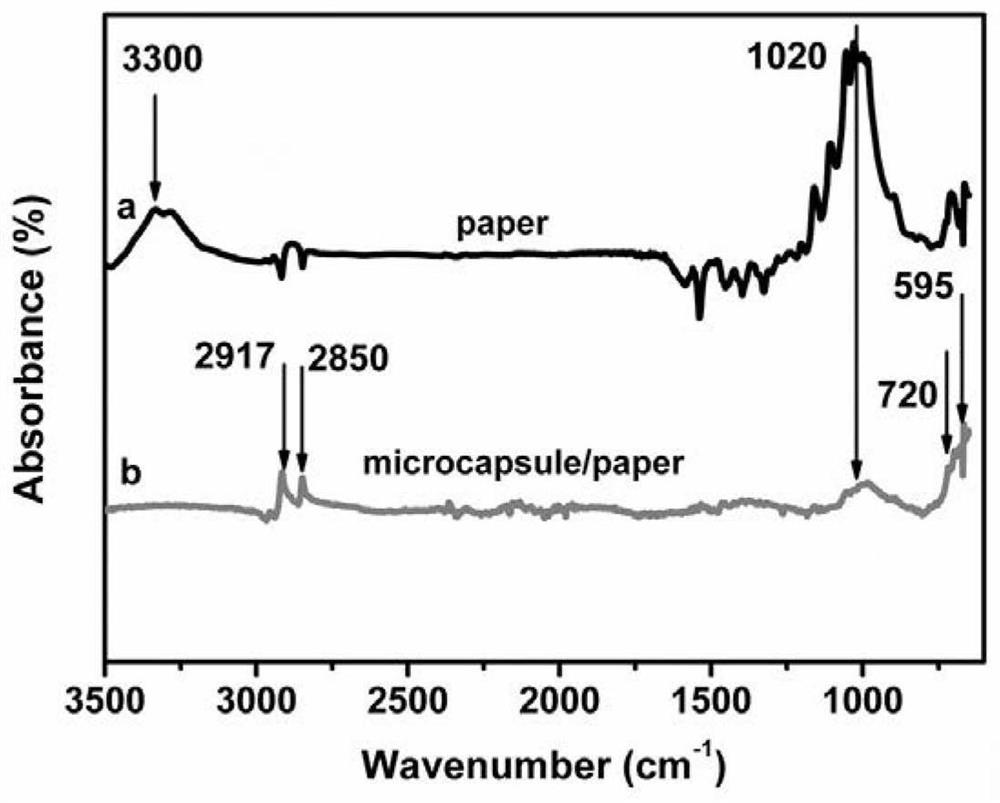

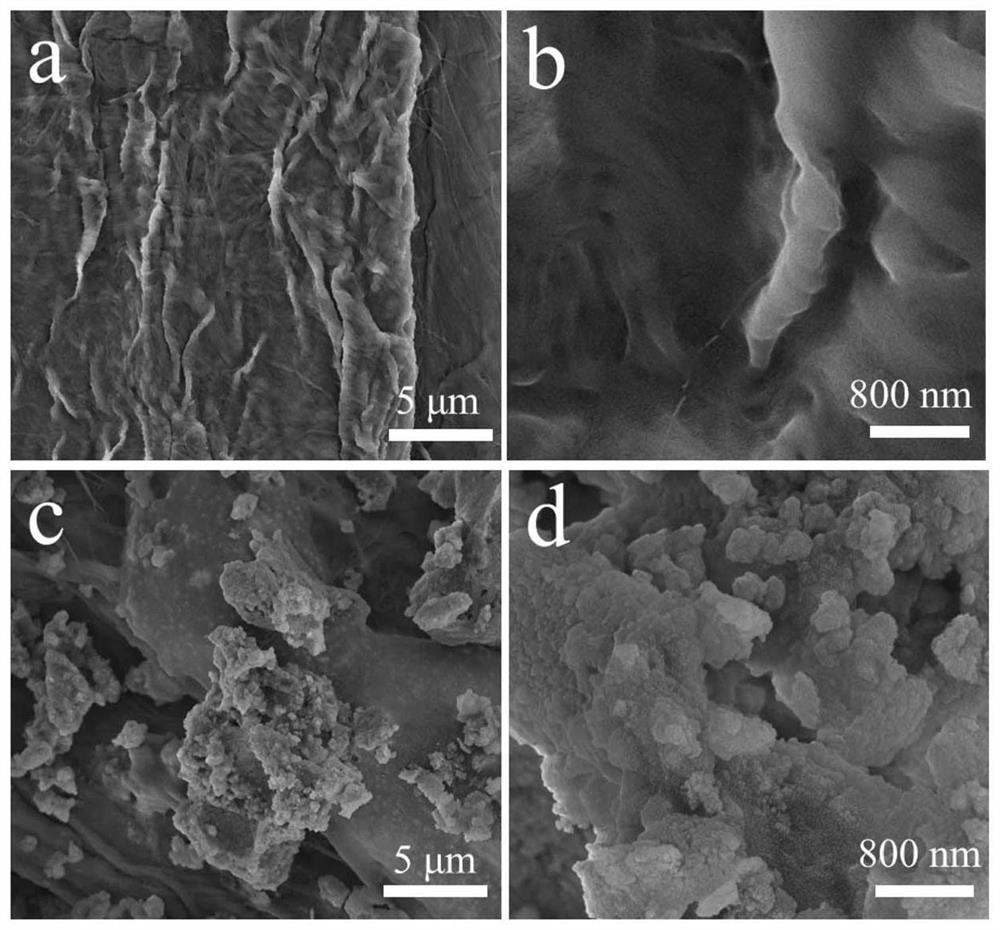

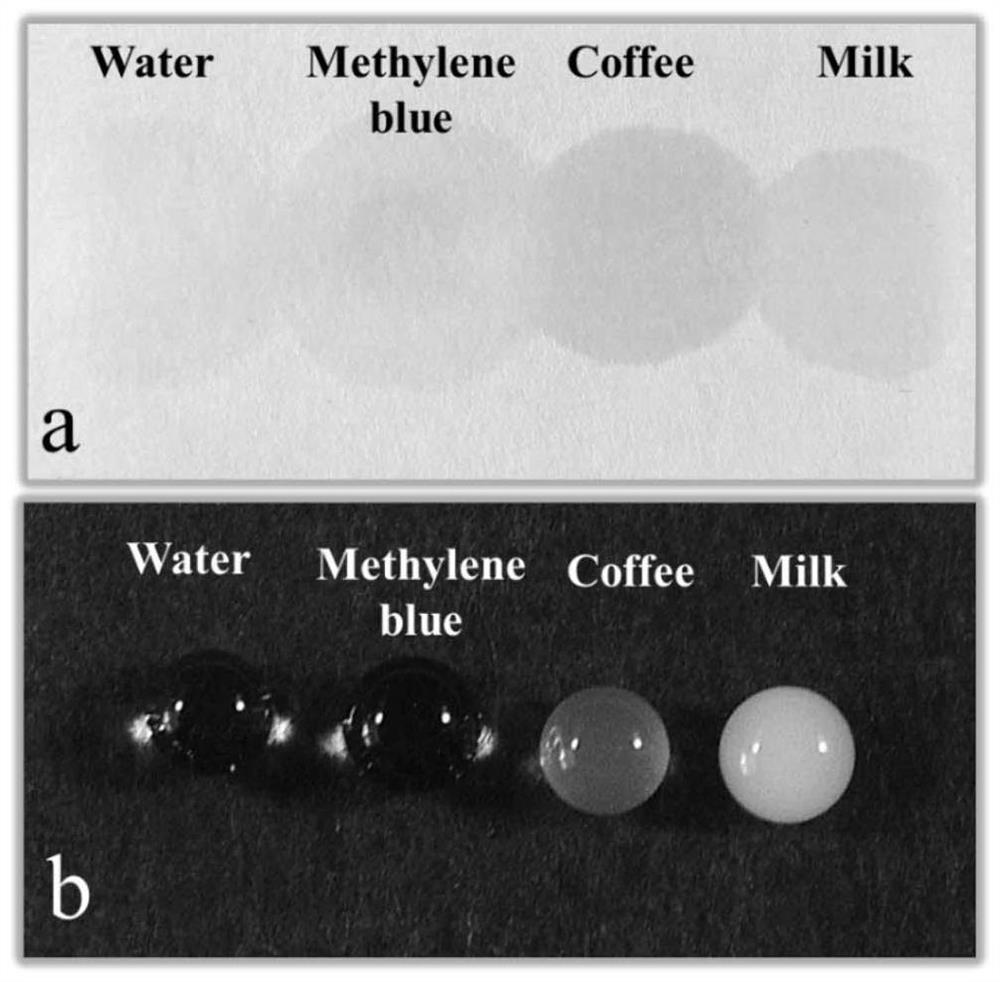

[0035] Embodiment 1, a kind of preparation method 1 of superhydrophobic paper

[0036] (1) Preparation of oleic acid-modified Fe3O4 nanoparticles: the chemical co-precipitation method was used to prepare oleic acid-modified Fe 3 o 4 nanoparticles. 9.100g of FeCl 3 ·6H 2 O and 3.645g FeCl 2 4H 2 O was ultrasonically dissolved in 50 mL of water, and then 220 μL of hydrazine hydrate was added to it, and after it was dispersed evenly, 23 mL of NH 3 ·H 2 O, sonicate for 10min; heat the reaction system to 70°C, and pass N 2 , mechanically stirred for 1.5h to fully react. After the reaction, it was poured into a large beaker, washed several times with deionized water until pH=7. Afterwards, the obtained precipitate was dispersed in a mixture of deionized water and ethanol with a volume ratio of 1:1, and then added into a three-necked flask, and oleic acid was added into the flask and stirred at 80° C. for 4 h. After the reaction, the system was cooled to room temperature, t...

Embodiment 2

[0042] Embodiment 2, a kind of preparation method 2 of superhydrophobic paper

[0043] (1) Preparation of oleic acid modified ferric oxide (OA-Fe 3 o 4 ) nanoparticles: oleic acid-modified Fe was prepared by chemical co-precipitation 3 o 4 nanoparticles. 9.100g of FeCl 3 ·6H 2 O and 3.645g FeCl 2 4H 2 O was ultrasonically dissolved in 50 mL of water, and then 250 μL of hydrazine hydrate was added to it, and after it was dispersed evenly, 25 mL of NH 3 ·H 2 O, ultrasonic 10min. The reaction system was heated to 70°C, and N 2 , mechanically stirred for 1.5h to fully react. After the reaction, it was poured into a large beaker, washed several times with deionized water until pH=7. Afterwards, the obtained precipitate was dispersed in a mixture of deionized water and ethanol with a volume ratio of 1:1, and then added into a three-necked flask, and oleic acid was added into the flask and stirred at 80° C. for 3.5 h. After the reaction, the system was cooled to room tem...

Embodiment 3

[0049] Embodiment 3, a kind of preparation method 3 of superhydrophobic paper

[0050] (1) Preparation of oleic acid modified ferric oxide (OA-Fe 3 o 4 ) nanoparticles: oleic acid-modified Fe was prepared by chemical co-precipitation 3 o 4 nanoparticles. 9.100g of FeCl 3 ·6H 2 O and 3.645g FeCl 2 4H 2 O was ultrasonically dissolved in 50 mL of water, and then 200 μL of hydrazine hydrate was added to it, and after it was dispersed evenly, 20 mL of NH 3 ·H 2 O, ultrasonic 8min. The reaction system was heated to 70°C, and N 2 , mechanically stirred for 1.5h to fully react. After the reaction, it was poured into a large beaker, washed several times with deionized water until pH=7. Afterwards, the obtained precipitate was dispersed in a mixture of deionized water and ethanol with a volume ratio of 1:1, and then added to a three-necked flask, 2 mL of oleic acid was added to the flask and stirred at 80° C. for 3 h. After the reaction, the system was cooled to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com