Electrolyte for high-voltage lithium-ion battery and lithium-ion battery containing the same

A lithium-ion battery and high-voltage technology, which is applied in the field of lithium-ion batteries and high-voltage lithium-ion battery electrolytes, can solve the problems of high-voltage lithium-ion batteries, lithium-ion battery performance deterioration, and lithium-ion battery performance degradation. , to achieve the effect of improving cycle performance, good high pressure resistance, and stable cycle performance

Active Publication Date: 2022-06-03

SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Commercial lithium-ion battery electrolytes are generally made of carbonate organic solvents and lithium hexafluorophosphate (LiPF 6 ), but the traditional electrolyte usually reduces the performance of lithium-ion batteries when the working voltage is too high. This is due to the commonly used organic carbonate solvents, such as chain carbonate DMC (dimethyl carbonate), EMC (methyl carbonate Ethyl ester), DEC (diethyl carbonate), and cyclic carbonates PC (propylene carbonate), EC (ethylene carbonate), etc. have low oxidation potentials, oxidative decomposition occurs under high voltage, and cannot exist stably

[0005] Conventional electrolytes can no longer meet the needs of high-voltage lithium-ion batteries, and high operating voltage is one of the main methods to improve the energy density of lithium-ion batteries, so the development of high-voltage electrolytes is very important

In addition, today's electronic products sometimes need to be used under extreme conditions (such as high or low temperature environments). Compared with conventional environments, the performance of lithium-ion batteries will deteriorate significantly when used under extreme conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

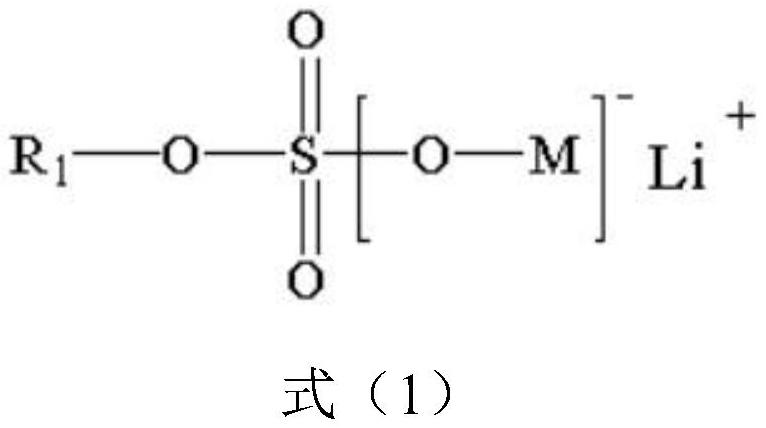

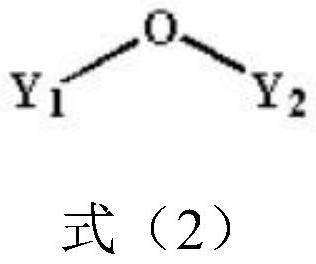

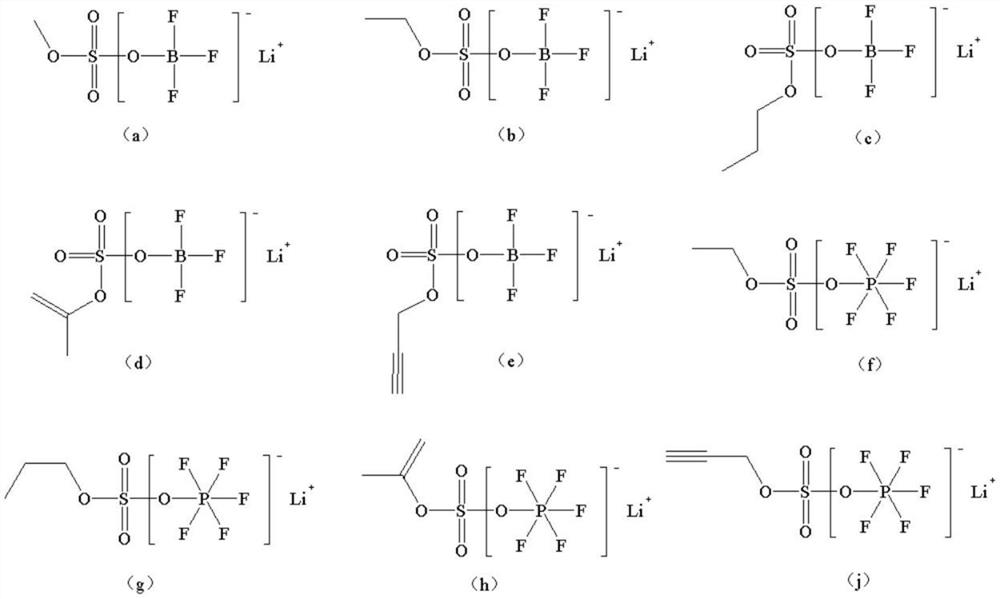

The invention belongs to the field of batteries, and discloses an electrolytic solution for a high-voltage lithium ion battery and a lithium ion battery containing the electrolytic solution. The electrolytic solution for high voltage lithium ion battery of the present invention comprises lithium salt, organic solvent, sulfur-containing lithium salt derivative additive, fluoroether additive and conventional additive, wherein, said conventional additive is selected from fluoroethylene carbonate, 1 , One or more of 3 propane sultone, ethylene carbonate, vinylene carbonate, propylene carbonate, lithium difluorophosphate. The electrolyte solution for high-voltage lithium-ion batteries adds sulfur-containing lithium salt derivatives, and the addition of sulfur-containing lithium salt derivatives improves the permeability of the SEI film to lithium ions, so the impedance is low, and the cycle performance and low-temperature performance are good. ; The fluoroether additives have a higher oxidation potential and lower viscosity, and the introduction of fluorine atoms makes the fluoroether additives have certain flame retardancy and good high temperature stability.

Description

Electrolyte for high voltage lithium ion battery and lithium ion battery containing the same technical field The present invention relates to the battery field, specifically relate to a kind of high-voltage lithium ion battery electrolyte and contain this electrolyte of lithium-ion batteries. Background technique With the advancement of science and technology and the continuous improvement of people's requirements for the quality of living environment, and the increasing exhaustion of fossil energy [0002] The problems of environmental pollution caused by energy consumption and consumption are becoming more and more serious, and the research and development of clean and renewable energy has become a top priority. target A large number of new energy sources have been developed and used before, such as solar energy, wind energy, tidal energy and geothermal energy, etc. Space constrained and requires proper conversion and storage for use. As a kind of green environmen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M10/0567H01M10/0569H01M10/0568H01M10/0525

CPCH01M10/0567H01M10/0569H01M10/0568H01M10/0525H01M2300/0025H01M2300/0028Y02E60/10

Inventor 杨冰杜建委吴杰曹青青

Owner SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com