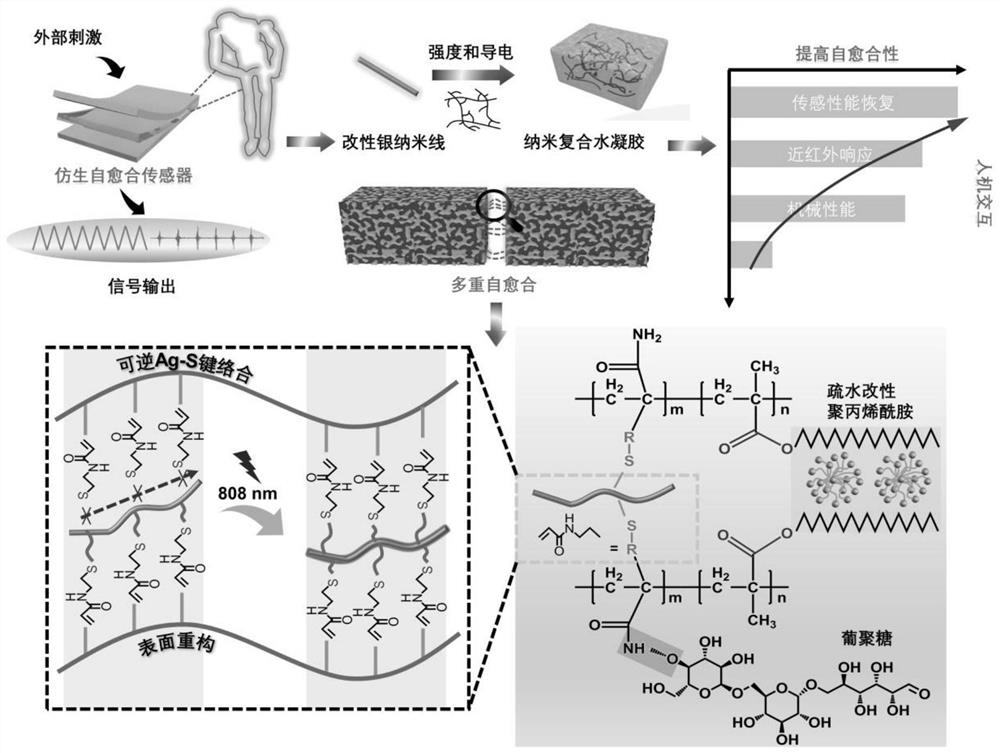

Self-healing conductive hydrogel and preparation method and application thereof

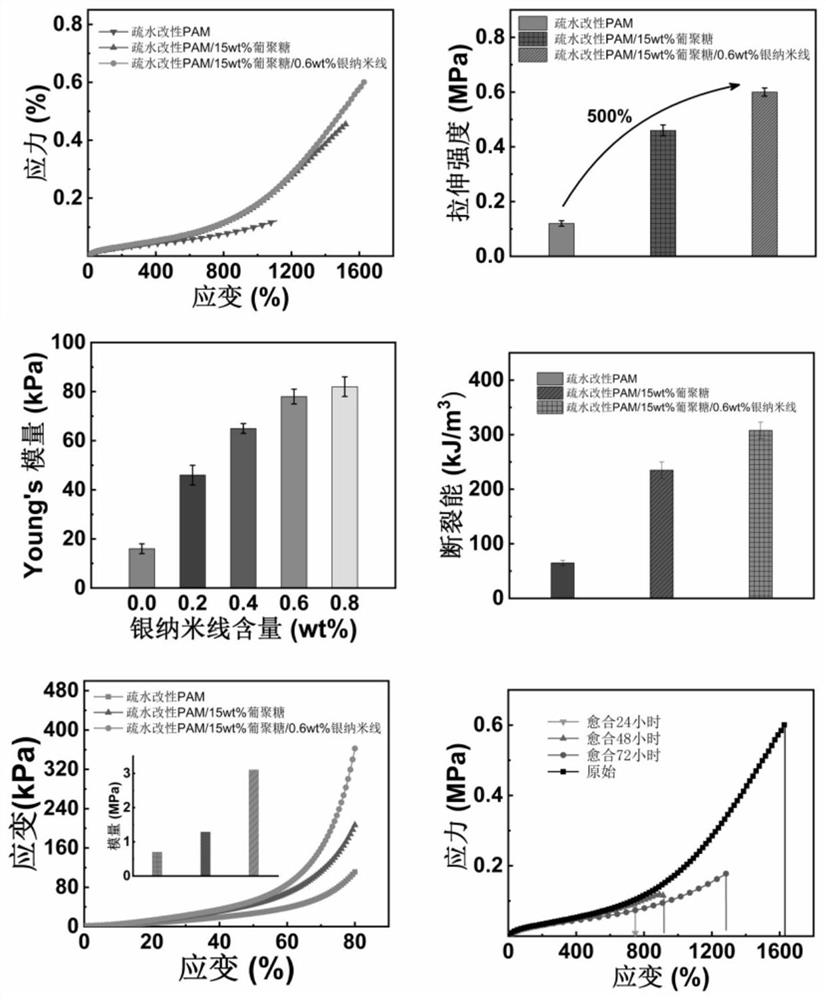

A conductive hydrogel, self-healing technology, applied in applications, sensors, diagnosis, etc., can solve the problems of low self-healing performance, poor biocompatibility, low mechanical strength, etc., to achieve extension and function, improve mechanical strength , the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

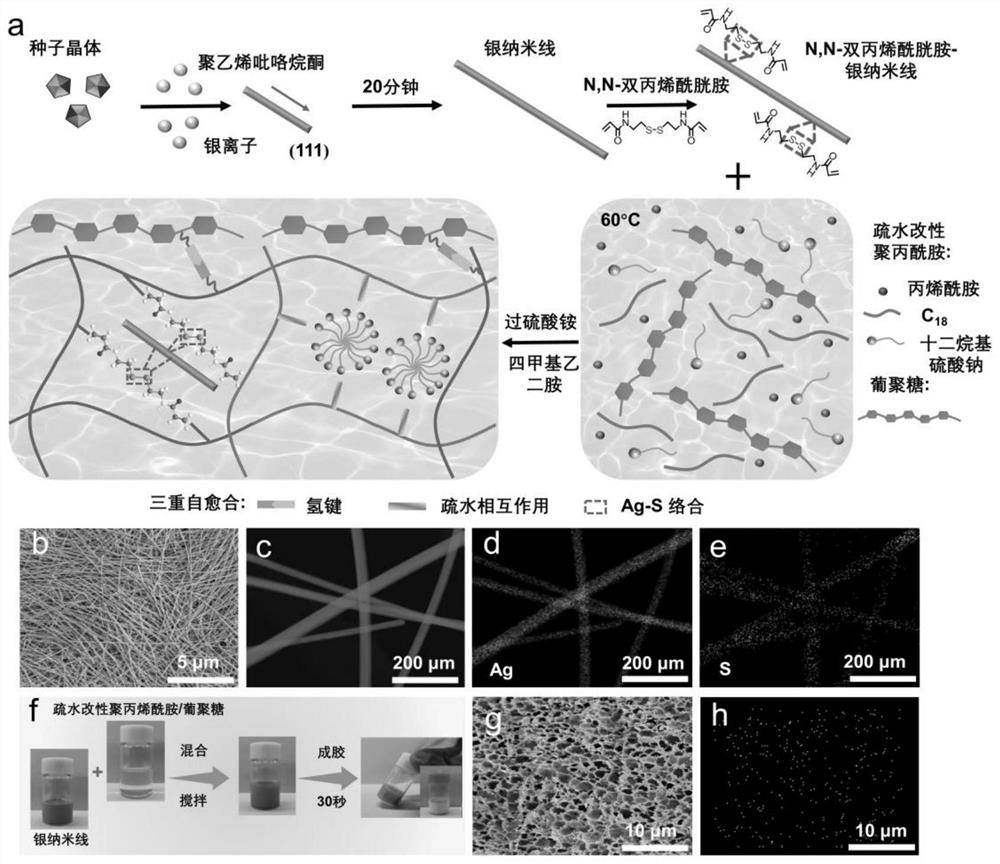

[0043] The self-healing conductive hydrogel provided in this example is prepared by the following method, and the specific steps are as follows:

[0044] (1) Preparation of prepolymer dispersion I: 0.68g acrylamide monomer, 0.14g sodium lauryl sulfate, 0.07g methacrylate stearate, 0.11g molecular weight are 80000g / mol dextran dissolved in In 1mL of water, the dissolution temperature is 60°C to obtain the hydrophobically modified acrylamide pre-polymerization dispersion I, and ultrasonically disperse the pre-polymerization dispersion I at 80 kHz for 30 minutes;

[0045] (2) Preparation of pre-polymerization dispersion II: 0.1mL concentration of 20mg / mL small molecule surface-modified silver nanowires (aspect ratio of 500) dispersion was added to pre-polymerization dispersion I and mixed, oscillated evenly to obtain Pre-polymerized dispersion II;

[0046] (3) Preparation of self-healing conductive hydrogel: Add 15 μL of 0.5 mM N,N,N′,N’-tetramethylethylenediamine aqueous soluti...

Embodiment 2

[0050] The self-healing conductive hydrogel provided in this example is prepared by the following method, and the specific steps are as follows:

[0051] (1) Preparation of prepolymer dispersion I: 0.68g acrylamide monomer, 0.14g sodium lauryl sulfate, 0.07g methacrylate stearate, 0.11g molecular weight are 80000g / mol dextran dissolved in In 1mL of water, the dissolution temperature is 60°C to obtain the hydrophobically modified acrylamide pre-polymerization dispersion I, and ultrasonically disperse the pre-polymerization dispersion I at 80 kHz for 30 minutes;

[0052] (2) Preparation of pre-polymerization dispersion II: 0.2mL concentration of 20mg / mL small molecule surface-modified silver nanowires (aspect ratio of 500) dispersion was added to pre-polymerization dispersion I and mixed, oscillated evenly to obtain Pre-polymerized dispersion II;

[0053] (3) Preparation of self-healing conductive hydrogel: Add 15 μL of 0.5 mM N,N,N′,N’-tetramethylethylenediamine aqueous soluti...

Embodiment 3

[0057] The self-healing conductive hydrogel provided in this example is prepared by the following method, and the specific steps are as follows:

[0058] (1) Preparation of prepolymer dispersion I: 0.68g acrylamide monomer, 0.14g sodium lauryl sulfate, 0.07g methacrylate stearate, 0.11g molecular weight are 80000g / mol dextran dissolved in In 1mL of water, the dissolution temperature is 60°C to obtain the hydrophobically modified acrylamide pre-polymerization dispersion I, and ultrasonically disperse the pre-polymerization dispersion I at 80 kHz for 30 minutes;

[0059] (2) Preparation of pre-polymerization dispersion II: 0.3mL concentration of 20mg / mL small molecule surface-modified silver nanowires (aspect ratio of 500) dispersion was added to pre-polymerization dispersion I and mixed, oscillated evenly to obtain Pre-polymerized dispersion II;

[0060] (3) Preparation of self-healing conductive hydrogel: Add 15 μL of 0.5 mM N,N,N′,N’-tetramethylethylenediamine aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com