Food raw material rich in slowly digestible and resistant starch as well as preparation method and application of food raw material

A resistant starch and slow-digesting technology, which is applied in the field of food raw materials rich in slow-digesting and resistant starch and its preparation, can solve the problems of unsuitable food processing and production, severe reaction conditions, etc., and achieve the improvement of slow-digesting starch and The effect of resistant starch content, simple operation process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

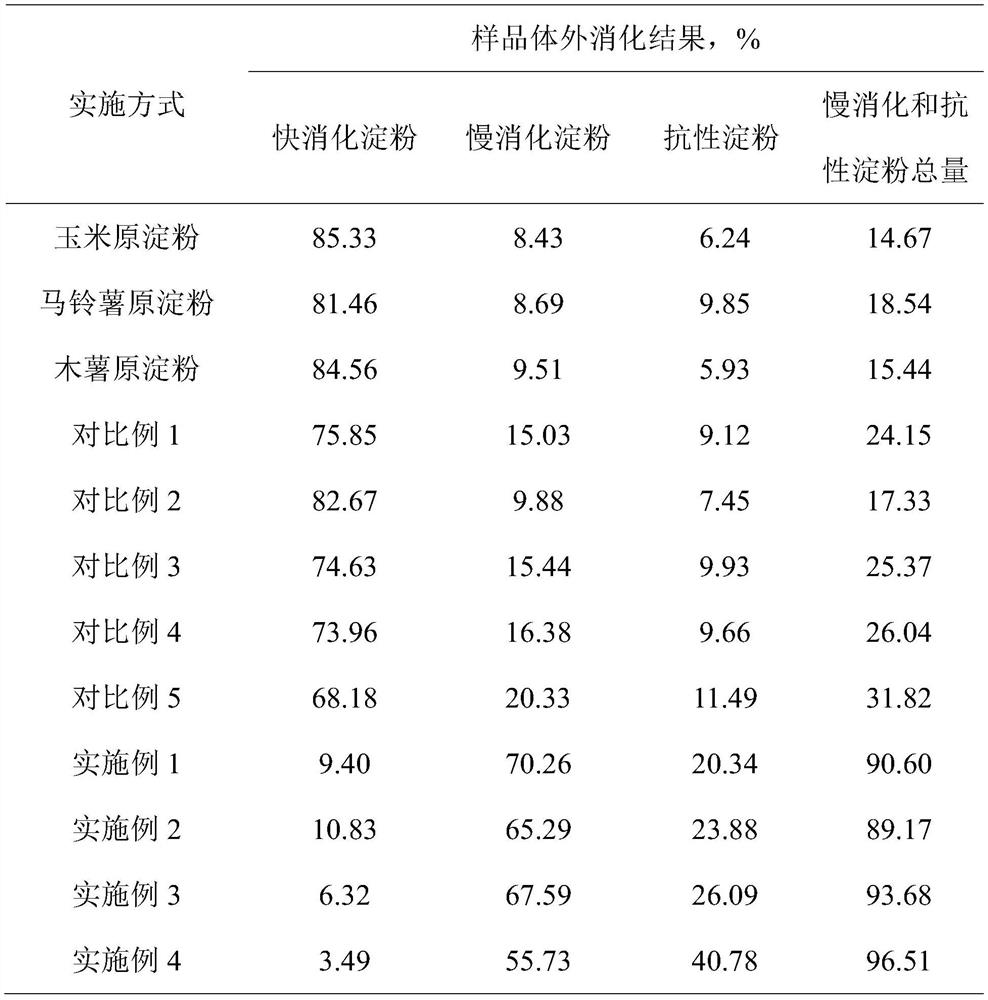

Embodiment 1

[0042] (1) Paste the starch: Press the starch dry group mass to formulate the corn starch milk in a concentration of 3% by weight, placed at 100 ° C boiling water bath, 0.5h, and placed in a 50 ° C water bath after gelation;

[0043] (2) Alcohol chipping: 2: 1 drop of 200 ml of water-free ethanol to step (1) by anhydrous ethanol and gentructured starch to step (1) to gelatinate starch, maintain stirring, induce starch precipitation, centrifuge at 4000R / min 20min, precipitated with anhydrous ethanol is washed twice, placed at 70 ° C oven for 6 h, pulverized, over 100 mesh sieve, weighed, sealed, to obtain alcohol chip starch;

[0044] (3) Fatty acid melting: Weighing the appropriate amount of lauric acid (melting point 46 ° C), melting it into a liquid fatty acid at 50 ° C;

[0045] (4) Kneading reaction: Step (2) The obtained liquid fatty acid obtained by mixing the alcohol chrome and step (3) is mixed in mass than 10: 1, placed in a closed container, and the control reaction te...

Embodiment 2

[0048] (1) Paste the starch: Press the starch dry base to be prepared from 100 ml of concentration of 6% by weight of potato starch milk, placed at 100 ° C boiling water bath, and placed at 70 ° C water bath after gelation;

[0049] (2) Alcohol chrose: 500 ml of tert-butanol to step (1) by 500 ml of tert-butanol to step (1) by a volume ratio of tert-butanol and gelamination starch to step (1) to maintain stirring, induce starch precipitation, centrifuge at 4000 R / min 20 min, precipitate washed four times with tert-butanol, placed at 50 ° C oven for 12h, pulverized, over 150 mesh sieve, weighed, sealed, to obtain alcohol chip starch;

[0050] (3) Fatty acid melting: Weighing the appropriate amount of myristic acid (melting point 58 ° C), melting it into a liquid fatty acid at 75 ° C;

[0051] (4) Kneading reaction: The liquid fatty acid obtained by the obtained alcohol chrome and step (3) is mixed in a mass ratio of 5: 1, and the control reaction temperature is carried out at 80 °...

Embodiment 3

[0054] (1) Paste the starch: Press the starch dry base to prepare 100 ml of a concentration of 10% by weight of the tapioca starch milk, placed at 100 ° C boiling water bath, and placed at 90 ° C water bath after gelation;

[0055] (2) Alcohol chipping: Positivopropanol and Pastein Starch can be added to 800 ml of n-propanol to step (1) to genize starch, maintain stirring, induce starch precipitation, centrifugation at 4000R / min 20min, precipitate washed six times with n-propol, was placed at 70 ° C oven for 6 h, pulverized, over 200 mesh sieve, weighed, sealed, to obtain alcohol chip starch;

[0056] (3) Fatty acid melting: Weighing an appropriate amount of palmitic acid (melting point 63 ° C), melting it into a liquid fatty acid at 90 ° C;

[0057] (4) Kneading reaction: Step (2) The obtained liquid fatty acid obtained by mixing the alcohol chipper and step (3) is mixed in mass than 15: 1, placed in a closed container for kneading, and the control reaction temperature is at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com