Novel deesterification, rectification and purification method for 2-methoxy-1-propanol acetate

A technology of propanol acetate and purification method, which is applied in the field of deesterification and rectification of 2-methoxy-1-propanol acetate, and can solve the problems of low product yield, high consumption reduction, frequent catalyst replacement, etc. problems, to achieve the effect of improving product purity, improving separation effect, and improving catalyst purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

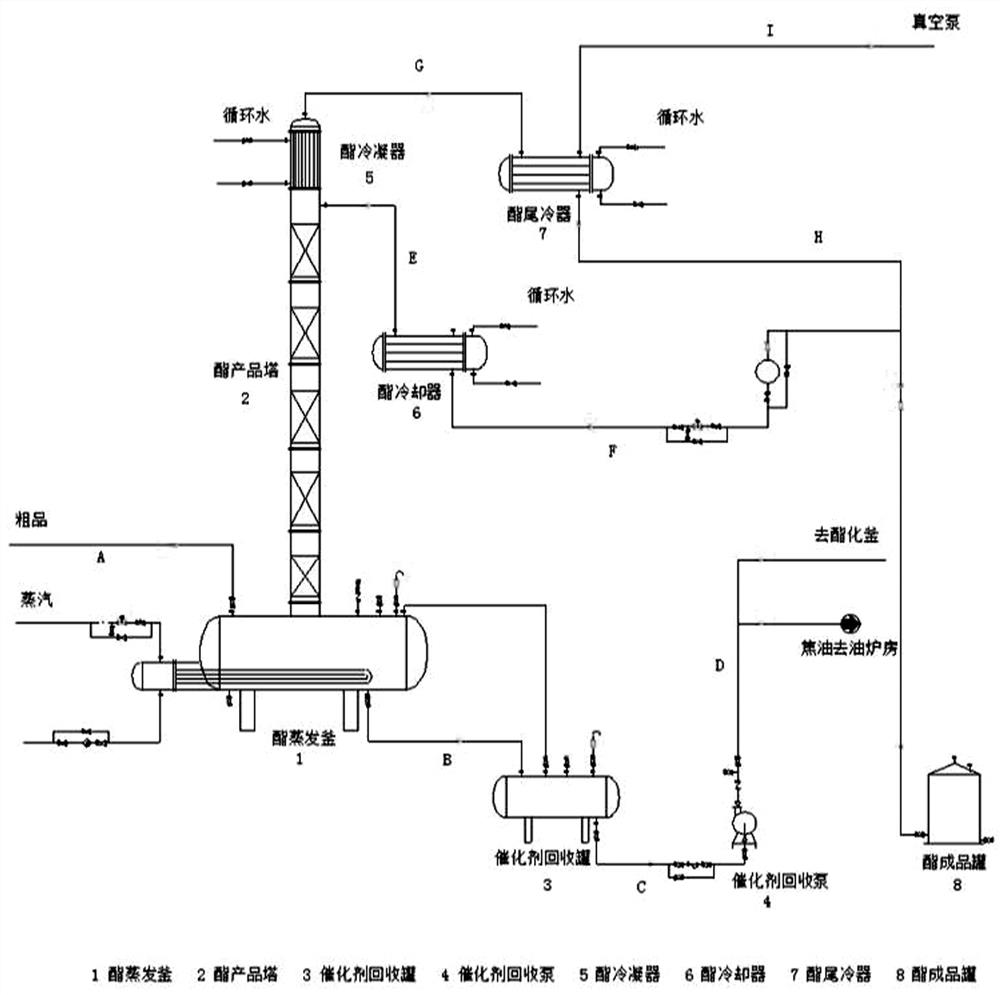

Image

Examples

Embodiment Construction

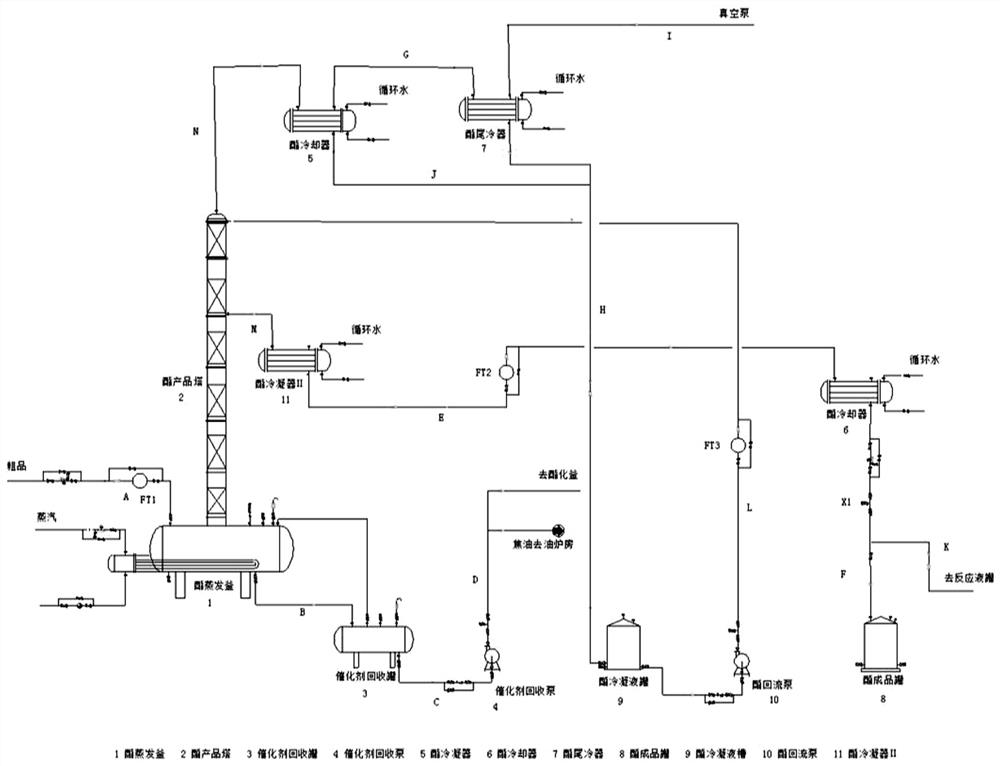

[0045] Such as figure 2 A kind of novel 2-methoxy-1-propanol acetate deesterification rectification purification method shown, comprises feed pump, ester product tower evaporator 1, ester product tower 2, catalyst recovery tank 3, catalyst Recovery pump 4, ester product condenser 5, ester cooler 6, ester tower tail cooler 7, ester product tank 8, ester condensate intermediate tank 9, ester product tower reflux pump 10, ester product condenser II 11, vacuum pump, crude product inlet Tower flow meter FT1, reflux flow meter FT2, finished product production flow meter FT3.

[0046] The outlet of the feed pump is connected to the inlet of the evaporator 1 of the ester product tower through pipeline A.

[0047] The outlet of the liquid phase at the bottom of the ester product tower 2 is connected to the inlet of the catalyst recovery tank 3 through a pipe B, and the gas phase port at the top of the ester product tower 2 is connected with the condenser 5 of the ester tower through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com