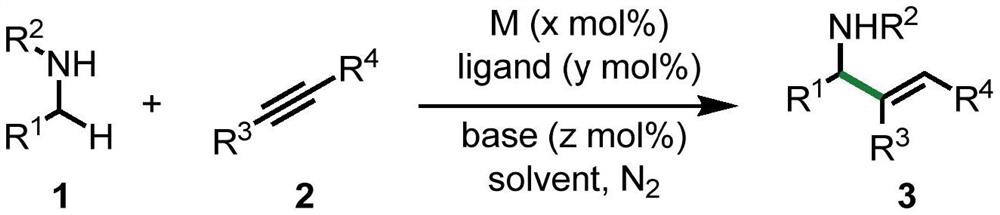

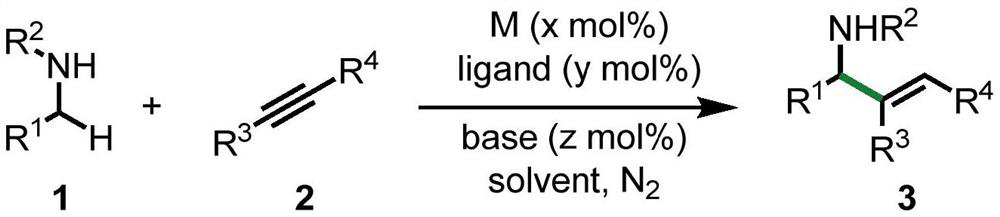

Method for synthesizing allylamine derivative

A technology for the preparation of allylamine derivatives, which is applied in the field of preparation of allylamine derivatives, can solve the problems of narrow applicability and poor atom economy, and achieve the effects of simple operation, avoiding subsequent processing, and convenient operation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

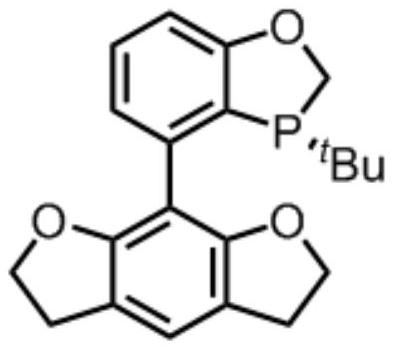

Method used

Image

Examples

Embodiment 1

[0027] Preparation of (E)-2,4,6-trimethyl-N-(1,2,3-triphenylallyl)benzosulfonamide

[0028]

[0029] In a nitrogen atmosphere, add raw material 1a (0.1mmol, 28.9mg), raw material 2a (0.2mmol, 35.6mg), K 3 PO 4 (0.04mmol, 8.4mg), Ni(cod) 2 (0.007mmol, 1.9mg), and PCy 3 (0.014mmol, 3.92mg), and finally Dioxane (0.5mL) was added, stirred at 120°C for 24 hours, cooled to room temperature, concentrated, and directly separated by column chromatography to obtain the target product 3a with a yield of 92%, 43.0mg. 1 H NMR (500MHz, CDCl 3 ) δ7.24(m,5H),7.20-7.17(m,1H),7.13-7.10(m,2H),7.06-7.01(m,3H),6.85(s, 2H),6.77-6.74(m, 4H), 6.52(s, 1H), 5.31(d, J=6.5Hz, 1H), 4.94(d, J=6.5Hz, 1H), 2.52(s, 6H), 2.23(s, 3H); 13 C NMR (126MHz, CDCl 3 )δ142.1, 140.1, 139.1, 138.9, 137.5, 135.9, 134.5, 131.9, 129.4, 129.2, 129.2, 128.5, 128.5, 127.8, 127.8, 127.6, 127.4, 126.9, 64.2, 23.0-HRMS, 20.8 / z calcd.for C 30 h 29 NO 2 SNa [M+Na] + :490.1817, found 490.1818.

[0030] Scale-up prepa...

Embodiment 2

[0033] Preparation of (E)-N-(2,3-diphenyl-1-(o-tolyl)allyl)-2,4,6-trimethylbenzonesulfonamide

[0034]

[0035] In a nitrogen atmosphere, add raw material 1b (0.1mmol, 30.3mg), raw material 2a (0.2mmol, 35.6mg), K 3 PO 4 (0.04mmol, 8.4mg), Ni(cod) 2 (0.007mmol, 1.9mg), and PCy 3(0.014mmol, 3.92mg), and finally Dioxane (0.5mL) was added, stirred at 120°C for 24 hours, cooled to room temperature, concentrated, and directly separated by column chromatography to obtain the target product 3b with a yield of 87%, 41.8mg. 1 H NMR (500MHz, CDCl 3 ) δ7.32-7.27(m,1H),7.20-6.97(m,9H),6.87-6.84(m,2H),6.81(s,2H),6.70-6.66(m,2H),6.36(s, 1H), 5.52(d, J=5.1Hz, 1H), 4.88(d, J=5.1Hz, 1H), 2.52(s, 6H), 2.21(s, 3H), 2.14(s, 3H); 13 C NMR (126MHz, CDCl 3 )δ142.0, 139.8, 138.8, 138.3, 137.0, 136.0, 135.9, 134.5, 131.9, 130.6, 129.1, 129.0, 128.9, 128.6, 127.8, 127.7, 127.5, 127.3, 126.8, 0, 123.2, 30; MS (ESI-TOF)m / z calcd. for C 31 h 31 NO 2 SNa[M+Na] + :504.1973,found 504.1975.

Embodiment 3

[0037] Preparation of (E)-N-(1-(2-fluorophenyl)-2,3-diphenylallyl)-2,4,6-trimethylbenzenesulfonamide

[0038]

[0039] In a nitrogen atmosphere, sequentially add raw material 1c (0.1mmol, 30.7mg), raw material 2a (0.2mmol, 35.6mg) to the reaction flask, K 3 PO 4 (0.04mmol, 8.4mg), Ni(cod) 2 (0.007mmol, 1.9mg), and PCy 3 (0.014mmol, 3.92mg), and finally Dioxane (0.5mL) was added, stirred at 120°C for 24 hours, cooled to room temperature, concentrated, and directly separated by column chromatography to obtain the target product 3c with a yield of 73%, 35.4mg. 1 H NMR (500MHz, CDCl 3 ) δ7.22-7.11(m,5H),7.06-6.85(m,7H),6.77(s,2H),6.76-6.72(m,2H),6.41(s,1H),5.52(d,J= 6.8Hz, 1H), 5.10(d, J=7.0Hz, 1H), 2.48(s, 6H), 2.22(s, 3H); 13 C NMR (126MHz, CDCl 3 )δ160.1(d, J=247.0Hz), 142.0, 139.5, 138.9, 137.6, 135.8, 133.7, 131.8, 129.5, 129.4(d, J=8.5Hz), 129.2, 129.1(d, J=3.8Hz) , 129.0,128.7,127.8,127.6,127.0,126.5(d,J=12.7Hz),124.0(d,J=3.5Hz), 115.4(d,J=21.6Hz),58.3(d,J=2.5Hz) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com