Microcapsule-containing self-detection and self-repair intelligent coating and preparation method thereof

A smart coating and microcapsule technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of imperfect self-detection function, limited loading of chromogenic molecules, lack of self-detection and self-repairing anti-corrosion coatings and other issues, to achieve good anti-corrosion effect, fill market vacancies, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

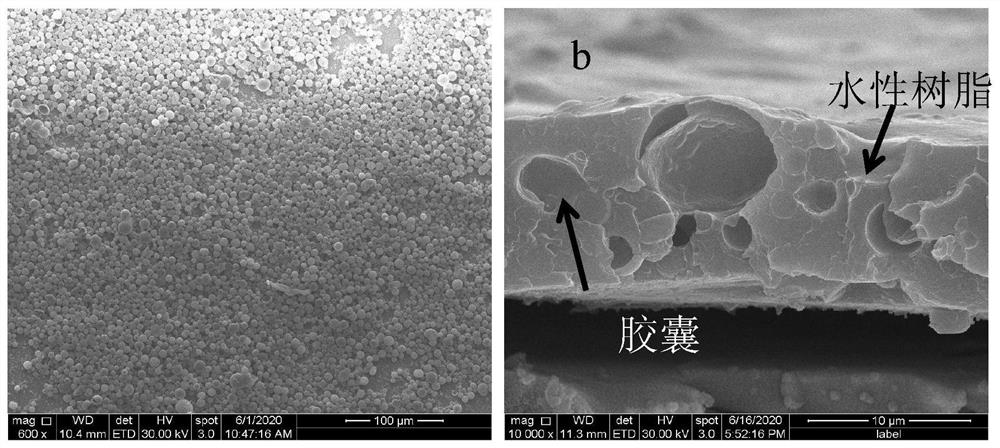

[0033] Step 1, the mixture of the polylactic acid and the epoxy bisphenol A monomer and the crystalline purple endose is dissolved in chloroform to the chloroform.

[0034] Step 2, adding 2 mg / ml of a 2 mg / ml of a 2 mg / ml of dodecylbenzene sulfonate in volume ratio of 2: 1, and a uniform emulsion was obtained using a 12000 rpm / min high-speed shear machine.

[0035] Step three, the emulsion in step two is placed in a 40 ° C oil bath and stirred and stirred at 600 rpm / min for 12 hours to obtain a microcapsule aqueous solution, and the microcapsule is obtained, and the microcapsules are further dispersed in deionized water. Microcapsules suspension.

[0036] Step 4, mixing the microcapsules in step three, the silica nanoparticle, dispersant, and aqueous epoxy resin to obtain a coating having self-detection self-repairing function, wherein the total resin mass in the total solid mass of the coating is 79%, micro The percentage of capsule mass is 15%, and the hydroxy-modified...

Embodiment 2

[0039] Step 1, the mixture of the polylactic acid and the epoxy bisphenol A monomer and the crystalline purple endose is dissolved in chloroform to the chloroform.

[0040] Step 2, adding 2 mg / ml of a 2 mg / ml of a 2 mg / ml of dodecylbenzene sulfonate in volume ratio of 2: 1, and a uniform emulsion was obtained using a 12000 rpm / min high-speed shear machine.

[0041] Step three, the emulsion in step two is placed in a 40 ° C oil bath and stirred and stirred at 600 rpm / min for 12 hours to obtain a microcapsule aqueous solution, and the microcapsule is obtained, and the microcapsules are further dispersed in deionized water. Microcapsules suspension.

[0042] Step 4, mix the microcapsules, silica nanoparticles, dispersants, and waterborne epoxy resin in step three, and the coating having self-detection self-repairing function, wherein the total resin mass in the total solid mass of the coating is 74%, micro The mass percentage of the capsule is 20%, and the hydroxy-modified ...

Embodiment 3

[0045] Step 1, the mixture of the polylactic acid and the epoxy bisphenol A monomer and the crystalline purple endose is 1: 1 to the chloroform to obtain the first mixture in chloroform.

[0046] Step 2, adding 2 mg / ml of a 2 mg / ml of a 2 mg / ml of dodecylbenzene sulfonate in volume ratio of 2: 1, and a uniform emulsion was obtained using a 12000 rpm / min high-speed shear machine.

[0047] Step three, the emulsion in step two is placed in a 40 ° C oil bath and stirred and stirred at 600 rpm / min for 12 hours to obtain a microcapsule aqueous solution, and the microcapsule is obtained, and the microcapsules are further dispersed in deionized water. Microcapsules suspension.

[0048] Step 4, mixing the microcapsules in step three, the silica nanoparticle, dispersant, and aqueous epoxy resin to obtain a coating having self-detection self-repairing function, wherein the total resin mass in the total solid mass of the coating is 79%, micro The percentage of capsule mass is 15%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com