Copper-based metal organic framework material immobilized laccase as well as preparation method and application thereof

A technology for immobilizing laccase and organic framework, applied in biochemical equipment and methods, immobilizing on/in organic carrier, oxidoreductase, etc., can solve the problem of poor stability, high cost and complicated process of immobilizing laccase problem, to achieve the effect of good bisphenol A removal ability, good activity retention, and high efficiency removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The synthesis method of Cu-PABA@Lac: first dissolve copper acetate (50mM), laccase (0.5mg / mL, purchased from sigma company) in water; PABA (12.5mM) is dissolved in acetate buffer (ABS, pH=7.0 ,50mM). The two solutions were then mixed in equal volumes and stirred at room temperature for more than 4 hours. The solid was collected by centrifugation and washed 3 times with deionized water.

Embodiment 2

[0037] The synthesis method of Cu-PABA: First, copper acetate (50 mM) was dissolved in water; PABA (12.5 mM) was dissolved in acetate buffer (ABS, pH=7.0, 50 mM). The two solutions were then combined and stirred at room temperature for 8 hours. The solid was collected by centrifugation and washed 3 times with deionized water.

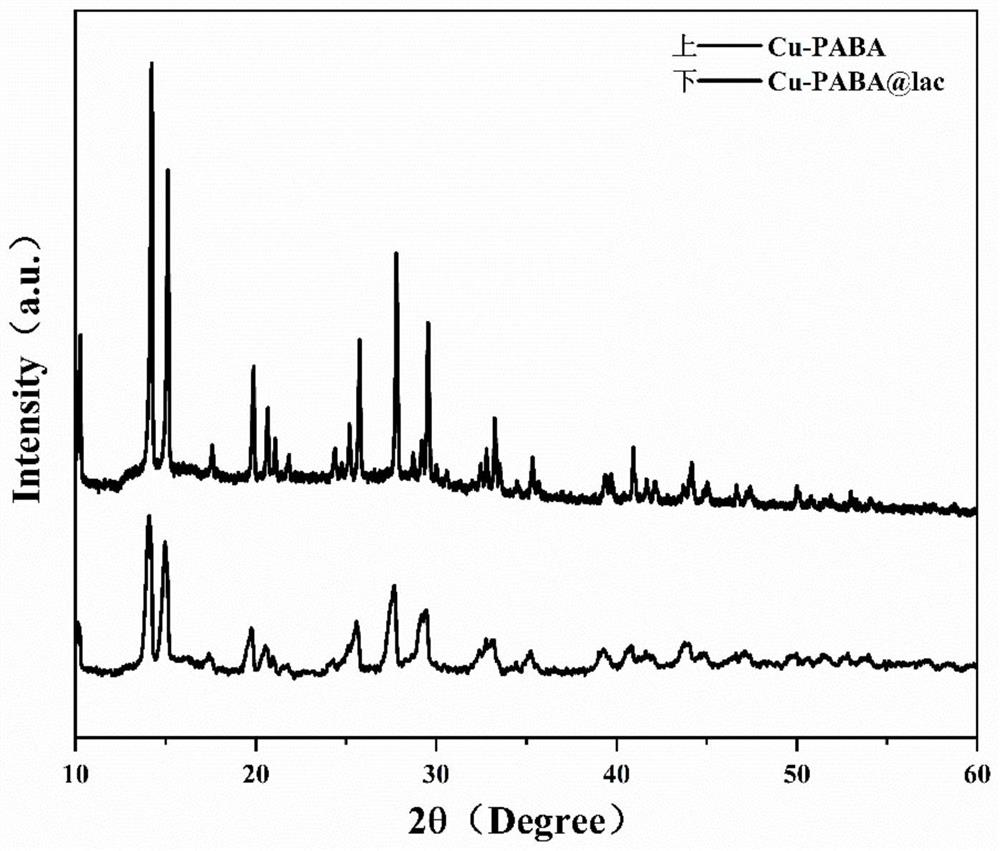

[0038] From figure 1 According to the XRD spectra of Cu-PABA and Cu-PABA@lac biocomposites, there is no obvious difference in crystal structure. The intensity of the diffraction peak of Cu-PABA@lac decreased, and the results showed that the successful loading of laccase and the introduction of laccase had little effect on the structure of Cu-PABA.

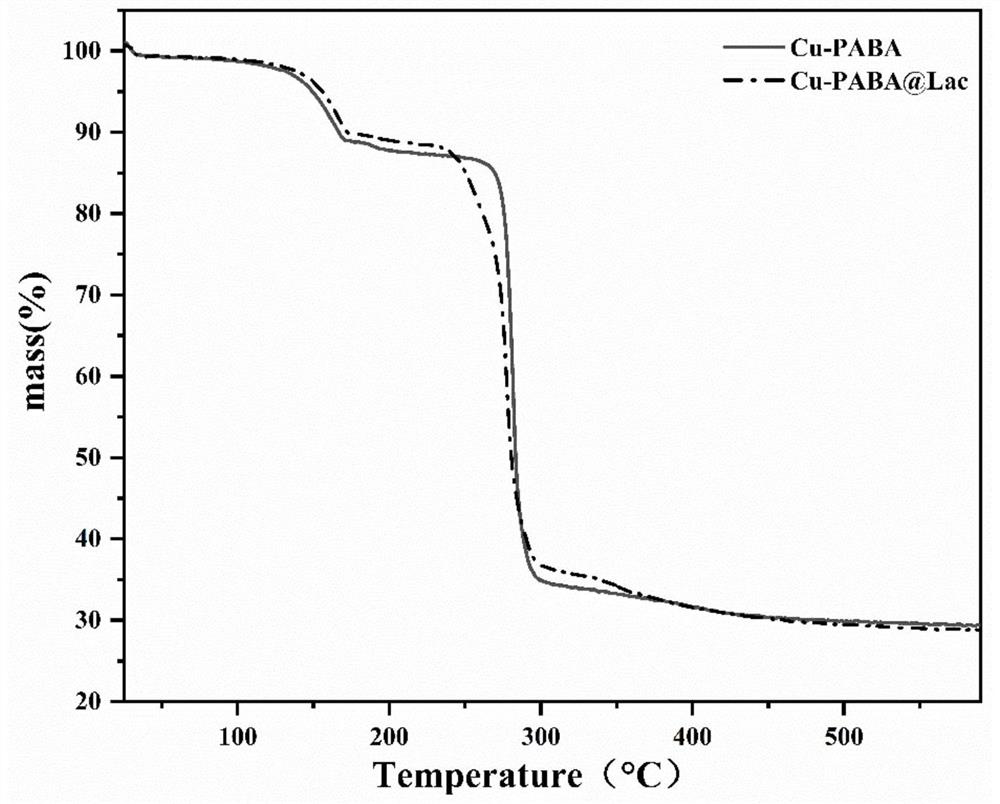

[0039] figure 2 The TGA curve can also demonstrate the success of laccase loading. From figure 2 As can be seen in the Cu-PABA curve, the mass loss (about 10%) below 160 °C is due to water evaporation, and the structure is destroyed above 260 °C. However, the TGA curves of Cu-PABA@Lac showed obvious ...

Embodiment 3

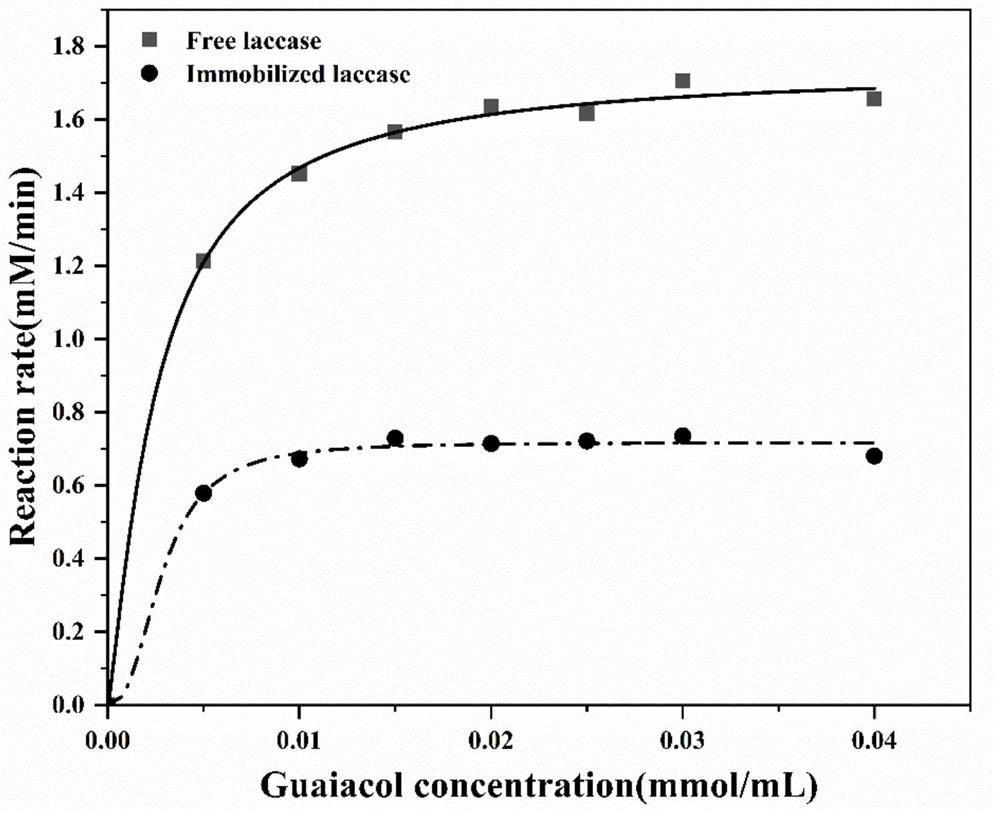

[0040] Example 3: Determination of immobilized enzyme retention activity

[0041] 50mmol / L sodium succinate was used as buffer solution (pH=4.5), and 0.04mmol guaiacol and laccase / immobilized enzyme were contained in 10mL reaction mixture. After reacting at 30°C for 30min, the absorbance was measured at 465nm. Taking the free enzyme activity as 100%, calculate the retained enzyme activity of the immobilized enzyme. The maximum retained enzyme activity of the product obtained in Example 1 is 41.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com