Method for improving hyaluronic acid yield

A technology of hyaluronic acid and hyaluronidase, applied in the field of bioengineering, can solve the problems of prolonging the fermentation time and decreasing the yield of hyaluronic acid, etc., and achieve the goal of improving mass transfer efficiency, biosynthesis rate, and mass transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Corynebacterium glutamicum strains were inoculated into 250mL shake flasks containing 50mL activation medium (brain heart infusion medium 37g / L), and cultivated for 10-12h.

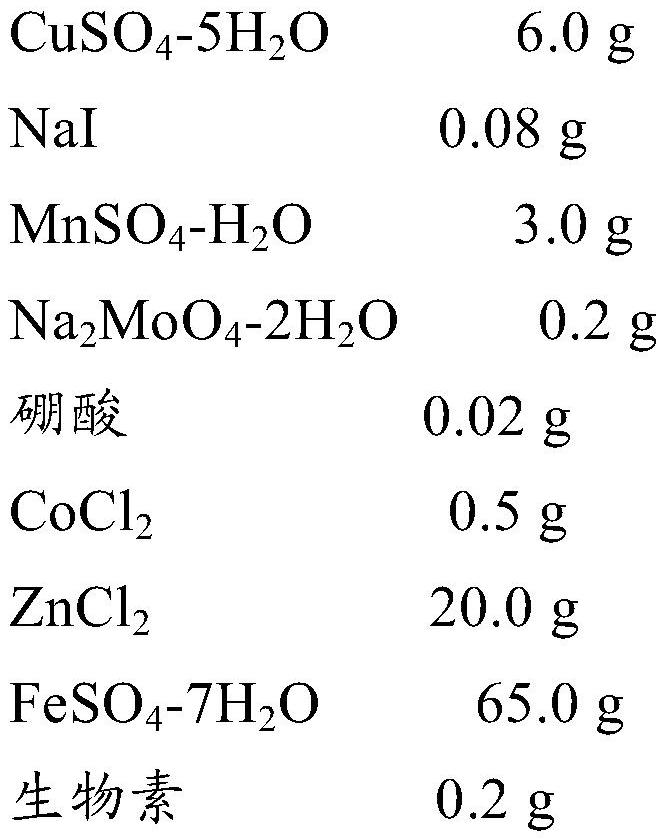

[0047] Cultivate at 30° C. for 15 hours, inoculate 50 mL of the above culture solution into a 2.5 L fermenter for cultivation. Medium: yeast extract 20g / L, peptone 3g / L, MgSO 4 1.2g / L, glucose 40g / L, PTM1 1mL / L, 5mL / L Tween 80.

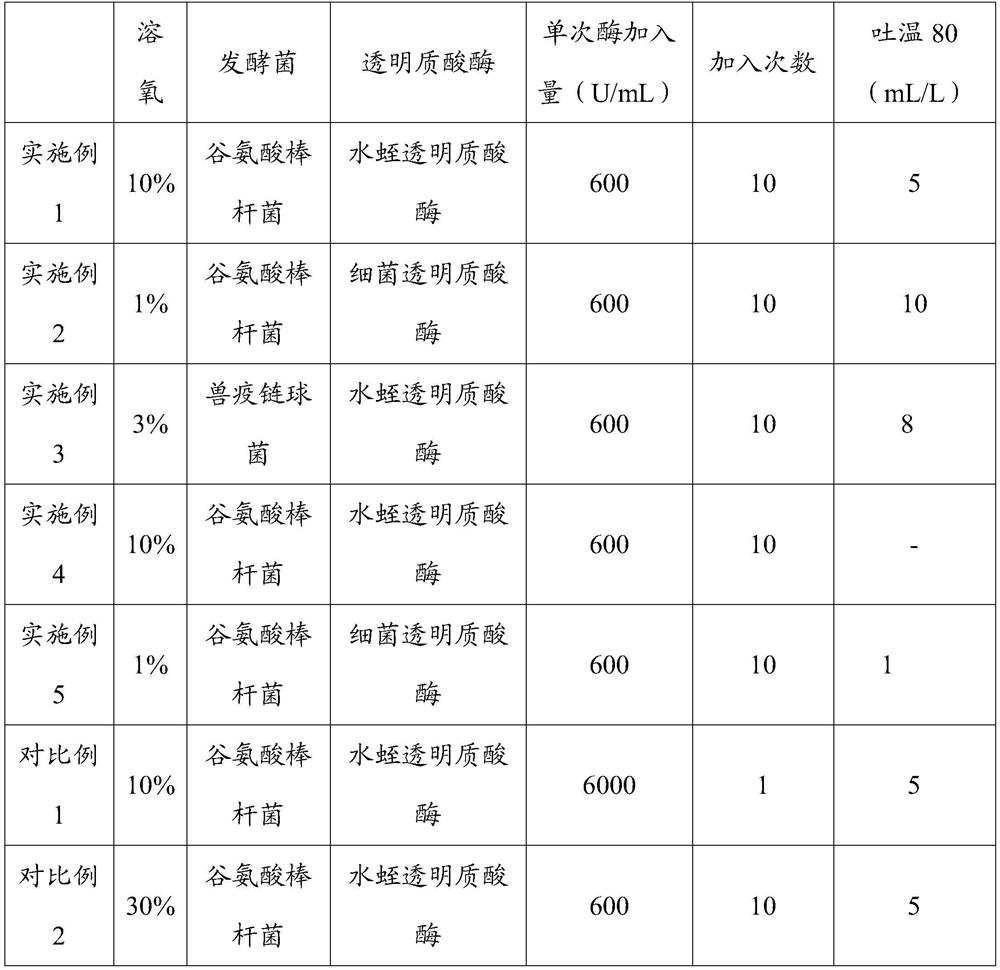

[0048] 24 hours before fermentation, the dissolved oxygen was linked with the rotational speed to keep the dissolved oxygen not lower than 10%, and 600 U / mL of leech hyaluronidase was added at the 8th hour. In the subsequent fermentation, as the hyaluronic acid content in the fermentation broth increases, the viscosity of the fermentation broth increases gradually, and the dissolved oxygen gradually decreases. The dissolved oxygen is coupled with the hyaluronidase, and whenever the dissolved oxygen is lower than 10%, , adding 600 U / mL of leech hyaluronidase, specific to...

Embodiment 2

[0050] Corynebacterium glutamicum strains were inoculated into 250mL shake flasks containing 50mL activation medium (brain heart infusion medium 37g / L), and cultivated for 10-12h.

[0051] Cultivate at 30°C for 15 hours, inoculate 50mL of the above culture solution into a 2.5L fermenter for culture medium: yeast extract 20g / L, peptone 3g / L, MgSO 4 1.2g / L, glucose 40g / L, PTM1 1mL / L, 10mL / L Tween 80.

[0052] 24 hours before fermentation, the dissolved oxygen was linked with the rotational speed to keep the dissolved oxygen not lower than 1%, and 600 U / mL of bacterial hyaluronan lyase was added at the 8th hour. In the subsequent fermentation, as the hyaluronic acid content in the fermentation broth increases, the viscosity of the fermentation broth increases gradually, and the dissolved oxygen gradually decreases. The dissolved oxygen is coupled with the hyaluronidase, and whenever the dissolved oxygen is lower than 1%, , adding 600 U / mL bacterial hyaluronan lyase, specific to...

Embodiment 3

[0054] Streptococcus zooepidemicus was inoculated into a 250mL shake flask containing 50mL activation medium (brain heart infusion medium 37g / L), and cultured for 10-12h.

[0055] Cultivate at 30°C for 15 hours, inoculate 50mL of the above culture solution into a 2.5L fermenter for culture medium: yeast extract 20g / L, peptone 3g / L, MgSO 4 1.2g / L, glucose 40g / L, PTM1 1mL / L, 5mL / L Tween 80.

[0056] 24 hours before fermentation, the dissolved oxygen was linked with the rotational speed to keep the dissolved oxygen not lower than 3%, and 600 U / mL of leech hyaluronidase was added at the 8th hour. In the subsequent fermentation, as the content of hyaluronic acid in the fermentation broth increases, the viscosity of the fermentation broth increases gradually, and the dissolved oxygen gradually decreases. The dissolved oxygen is coupled with the hyaluronidase, and whenever the dissolved oxygen is lower than 3% , add 600U / mL leech hyaluronidase, and add 10 times in total. After cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com