Axial continuous shearing strain piezoelectric fiber composite material and preparation method thereof

A fiber composite material, piezoelectric technology, applied in the material selection of piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, etc. Large-scale structure preparation, discontinuous stress-strain transfer, difficult to control angles, etc., to achieve the effect of continuous stress, stable product performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

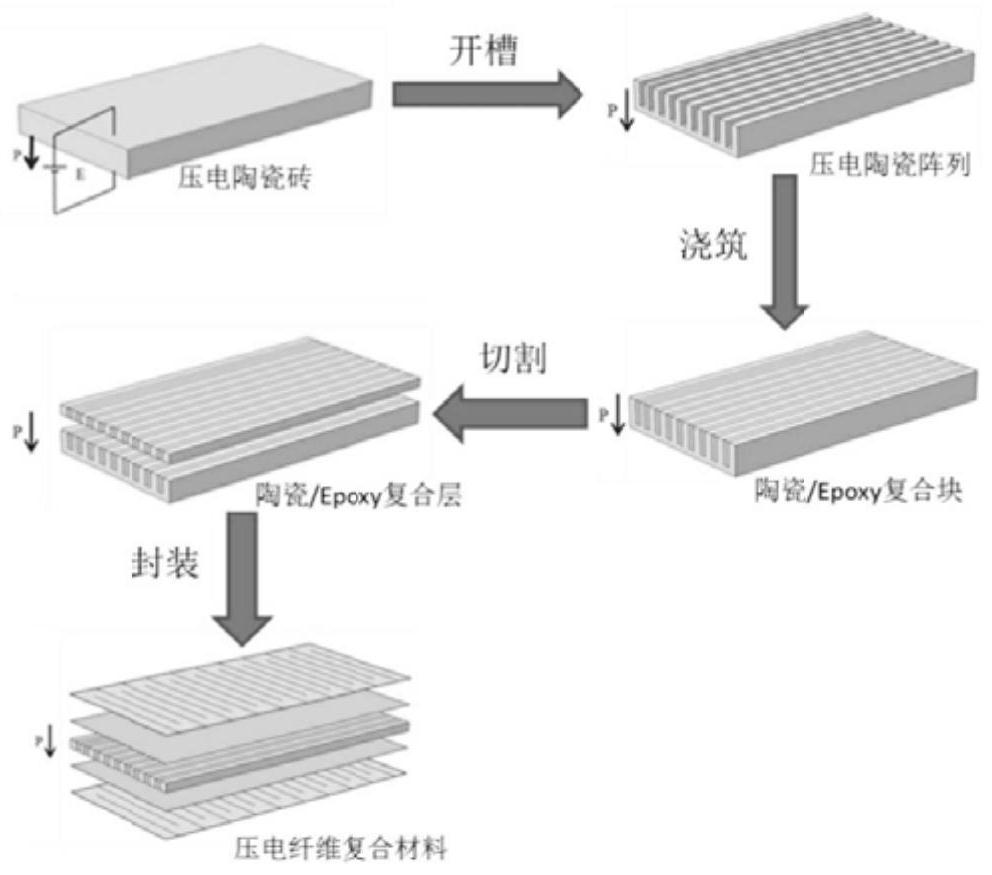

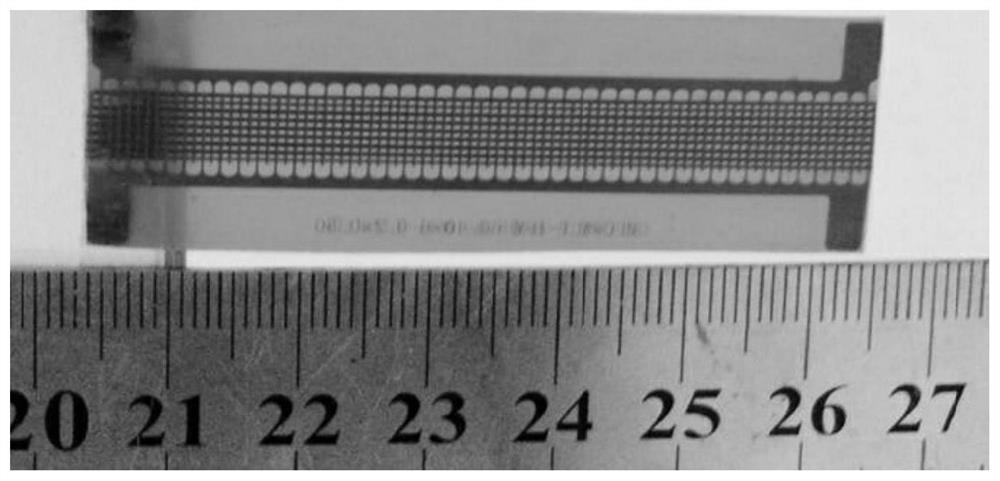

[0030] Large-sized ceramic tiles were prepared by traditional solid-phase synthesis method, and silver electrodes were plated on the upper and lower surfaces, and then placed in a 120°C silicone oil bath, and polarized in the thickness direction at an electric field strength of 3kV / mm for 15min. Polish the silver electrode of the obtained polarized Mn-doped lead zirconate titanate piezoelectric ceramic brick (PZT-Mn) with a polishing machine, and use a diamond linear cutter to slot the ceramic brick along the polarization direction to keep the width of the ceramic sheet and spacing are 0.35mm. Fill the epoxy resin in the ceramic array, and cure it in a vacuum environment at 30°C for 6 hours to obtain a piezoelectric ceramic fiber / polymer composite material, and then cut along the vertical polarization direction to obtain a thickness of 0.3mm and a length of 60mm. A piezoelectric fiber composite layer with a width of 6 mm. Then compound the interdigitated electrodes on the upp...

Embodiment 2

[0032] The preparation method is the same as in Example 1, except that the axial strain of the piezoelectric fiber composite material is tested with the electric field amplitude variation (within the range of 0-2kV / mm) at different electric field frequencies, and the electric field frequencies are 0.1Hz, 1Hz, 2Hz and 10Hz. Depend on Figure 6 It can be seen that with the increase of the electric field frequency, the maximum axial strain of the piezoelectric fiber composite material decreases, and the axial strain reaches the maximum when the electric field frequency is 0.1 Hz.

Embodiment 3

[0034] The preparation method is the same as in Example 1, the material system of the piezoelectric ceramic fiber in the piezoelectric fiber composite is changed, and Mn-doped lead zirconate titanate piezoelectric ceramics (PZT-Mn) and lead zirconate titanate are prepared by testing respectively. The piezoelectric ceramic (PZT-5) two piezoelectric material systems were tested on the bending deformation of the piezoelectric fiber composite. The results of piezoelectric fiber composite materials under the test conditions of electric field frequency 1Hz and electric field amplitude 2.0kV / mm are as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com