Preparation method of nano lithium carbonate

A lithium carbonate and nanotechnology, applied in the direction of nanotechnology, lithium carbonate;/acid carbonate, etc., can solve the problems of low membrane filtration efficiency and achieve high reactivity, simple steps and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

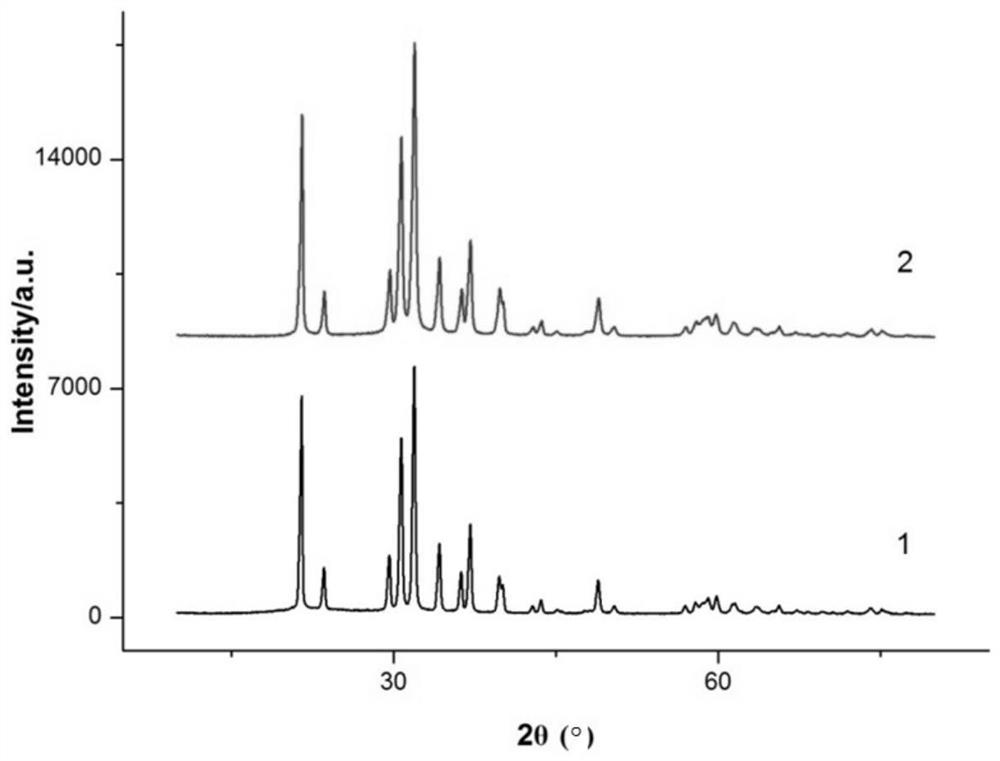

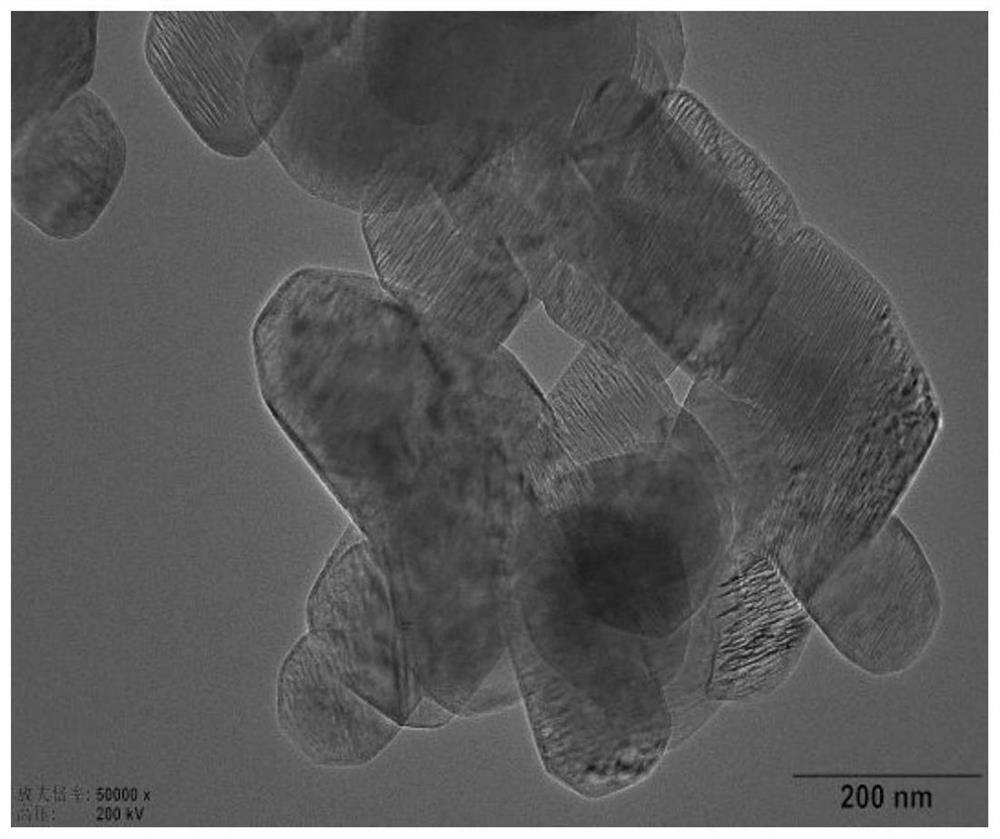

[0023] At room temperature, dissolve high-purity lithium carbonate in 25ml of water until saturated, filter the undissolved lithium carbonate, and reserve the undissolved lithium carbonate for the next process to prepare lithium carbonate solution, and place the filtrate at -50~-40°C Pre-freeze in a cold trap to prepare small-particle ice cubes, and vacuum-dry for 12 hours under the condition of maintaining freezing to obtain highly active, ultrafine white lithium carbonate powder. The XRD pattern of nano-lithium carbonate product is as follows figure 1 As shown in 1, the shape is as figure 2 shown. From figure 1 In 1, it can be seen that there is only one pure phase of lithium carbonate, figure 2 It can be seen that the particle size is about 100 nanometers, and it is in a dispersed state, not dense.

Embodiment 2

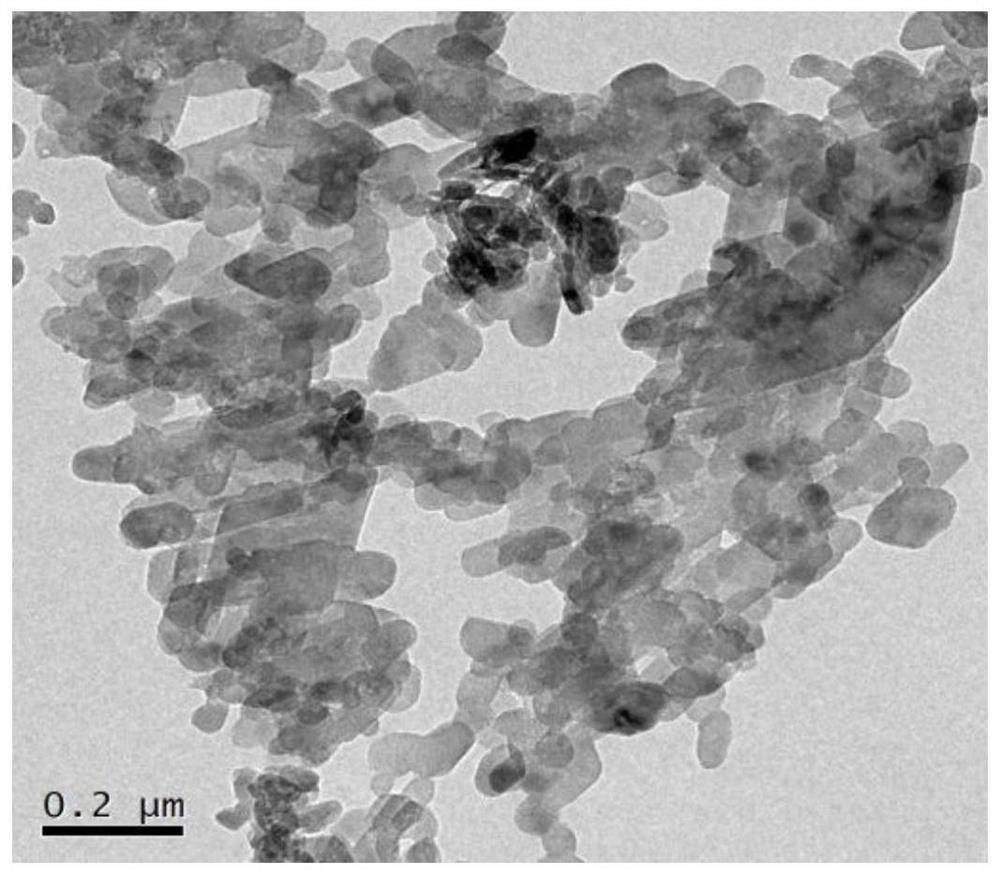

[0025] At room temperature, dissolve high-purity lithium carbonate in 25ml of water until saturation is reached, filter the undissolved lithium carbonate, and reserve the undissolved lithium carbonate for the next process to prepare a lithium carbonate solution. Take 5ml of the saturated solution and add 20mL of water. Pre-freeze in a cold trap at -50 to -40°C to prepare small-particle ice cubes, and then vacuum-dry them for 12 hours while maintaining freezing conditions to obtain highly active, ultrafine white lithium carbonate powder. looks like image 3 As shown, it can be seen that the particles are about ~30 nanometers, and are in a dispersed state, not dense.

Embodiment 3

[0027] At room temperature, dissolve high-purity lithium carbonate in 25ml of water until it reaches saturation, filter the undissolved lithium carbonate, save the undissolved lithium carbonate for the next process to prepare lithium carbonate solution, add 2 to 5ml of ethanol to the filtrate, and instantly A large amount of white emulsion is produced, and the white emulsion is placed in a cold trap at -50 to -40°C, and the prepared small-particle ice cubes are evacuated for 12 hours under freezing conditions to obtain highly active, ultrafine white lithium carbonate powder. The XRD pattern of nano-lithium carbonate product is as follows figure 1 As shown in 2, from figure 1 In 2, it can be seen that there is only one pure phase of lithium carbonate, and the morphology is as follows Figure 4 As shown, it can be seen that most of the particles are smaller than 100 nanometers, and are in a dispersed state, not dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com