Black light shielding master batch, black light shielding polyester film and preparation method

A light shielding and black technology, applied in the field of polymer materials, can solve the problems of non-uniform light shielding performance of films, irregular aggregation of black pigment particles, influence of film gloss and flatness, etc., to improve light shielding performance and tinting strength and high coverage at an affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

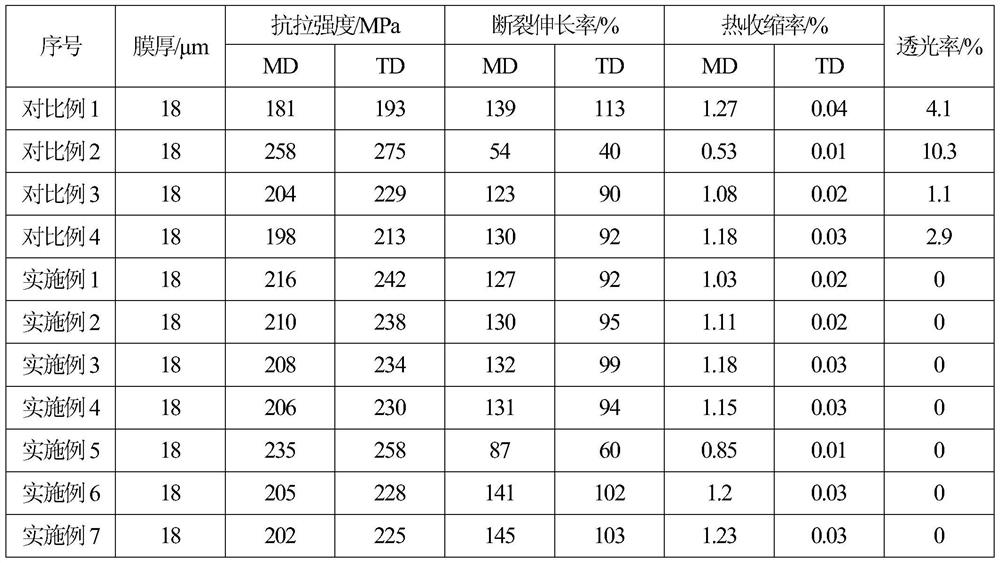

Examples

Embodiment 1

[0052] Preparation of black light shielding masterbatch:

[0053] (1) Add 0.14kg bis-(γ-triethoxysilylpropyl)tetrasulfide and 0.06kgγ-mercaptopropyltrimethoxysilane to a mixture of 9kg ethanol and 0.8kg water, stir and adjust with acetic acid The pH value of the mixed solution was 5.1 to obtain a coupling agent mixed solution. Add 89.9kg of high-pigment furnace black (average particle size 32 nanometers) and 10kg carbon fiber (7 microns in diameter, 30 microns in length) into a high-speed mixer (5000 rpm), spray 5kg of sprayed coupling agent mixture, Mix at a high speed for 35 minutes at 70° C., then heat up to 115° C. and mix at a high speed for 80 minutes, and discharge to obtain a modified black additive.

[0054] (2) Mix 30kg of the modified black additive and 70kg of polyester evenly, extrude, pelletize and slice, and extrude and pelletize into slices in a co-rotating parallel twin-screw extruder at 275°C±5°C to obtain black light-shielding masterbatch.

[0055] Prepara...

Embodiment 2

[0058] Preparation of black light shielding masterbatch:

[0059] (1) Add 0.35kg of bis-(γ-triethoxysilylpropyl) tetrasulfide and 0.15kg of γ-mercaptopropyltrimethoxysilane to a mixture of 7.5kg of ethanol and 2kg of water, stir and adjust with acetic acid The pH of the mixture was 5.1. Add 89.9kg of high-pigment furnace black (average particle diameter of 32 nanometers) and 10kg of carbon fibers (7 microns in diameter, 30 microns in length) into a high-speed mixer (5000 rpm), and spray 2 kg of misty alcohol containing a coupling agent. The water mixture was mixed at a high speed of 60°C for 30 minutes, then heated to 110°C and mixed at a high speed for 60 minutes, and discharged to obtain a modified black additive.

[0060] Step (2) and the preparation of the black light-shielding polyester film were the same as in Example 1, and the process was the same to prepare a black light-shielding polyester film (thickness: 18 microns).

Embodiment 3

[0062] Preparation of black light shielding masterbatch:

[0063] (1) Add 0.07kg bis-(γ-triethoxysilylpropyl)tetrasulfide and 0.03kgγ-mercaptopropyltrimethoxysilane to the mixture of 9.5kg ethanol and 0.4kg water, stir and wash with acetic acid Adjust the pH of the mixture to 5.1. Add 89.9kg of high-pigment furnace black (average particle diameter of 32 nanometers) and 10kg of carbon fibers (7 microns in diameter, 30 microns in length) into a high-speed mixer (5000 rpm), and spray 10 kg of misty alcohol containing a coupling agent. The water mixture was mixed at a high speed for 50 minutes at 70° C., then heated to 120° C. and mixed at a high speed for 120 minutes, and discharged to obtain a modified black additive.

[0064] Step (2) and the preparation of the black light-shielding polyester film were the same as in Example 1, and the process was the same to prepare a black light-shielding polyester film (thickness: 18 microns).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com