Surface treatment method for enhancing adhesive property of epoxy resin adhesive-bonded joint

A technology of epoxy resin glue and bonding performance, which is applied in the direction of surface pretreatment bonding methods, adhesives, etc., can solve the problems of reducing the bonding performance of bonded joints, reducing the bonding strength of materials, and stress concentration, etc., to achieve improved Adhesive performance, the effect of enhancing adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

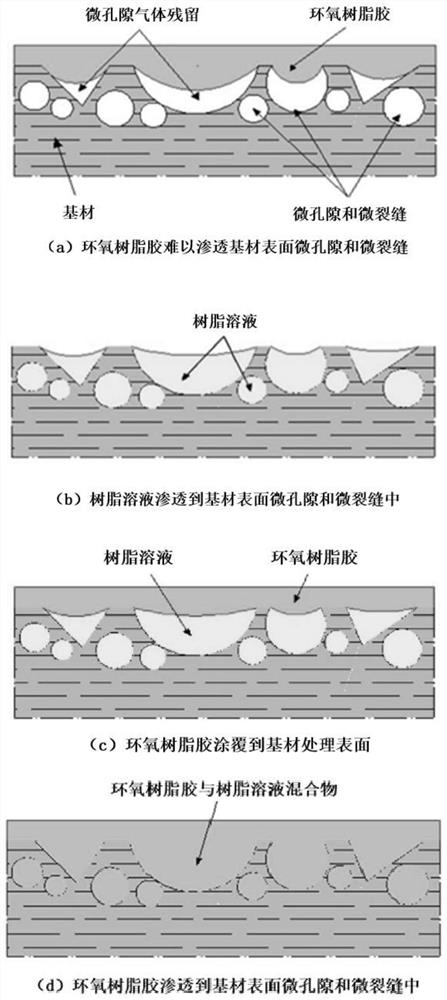

Problems solved by technology

Method used

Image

Examples

Embodiment approach

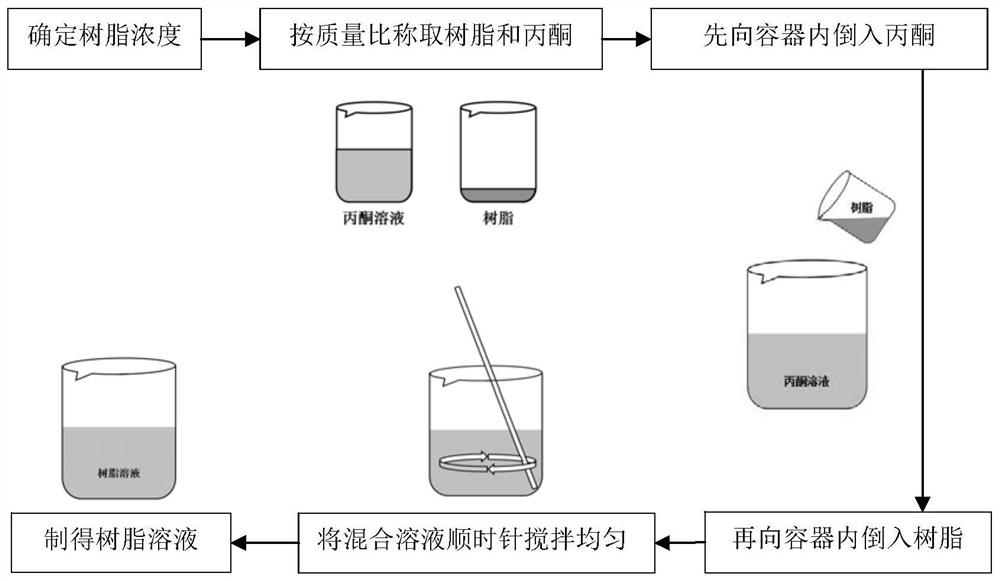

[0045] (1) The resin solution is formed by mixing resin and acetone, and the resin accounts for 5% to 20% of the total mass of the resin solution, and the rest is acetone. The resin in the resin solution is the same as the resin in the epoxy resin glue. The resin solution needs to be formulated according to the mass fraction ratio. Since the acetone solvent is extremely volatile, it needs to be ready-to-use. Therefore, it is necessary to coat the resin solution on the bonding interface of the substrate within 30 minutes after the resin solution is prepared to ensure that the resin solution on the surface of the substrate at optimal concentration.

[0046] (2) The base material is at least one of bamboo-based composite materials such as wood, bamboo, recombined bamboo, wood-based engineering composite materials such as glued wood, metal materials such as steel plates and aluminum plates, fiber-reinforced composite materials such as carbon fiber boards, and glass fiber cloth. ...

Embodiment 1

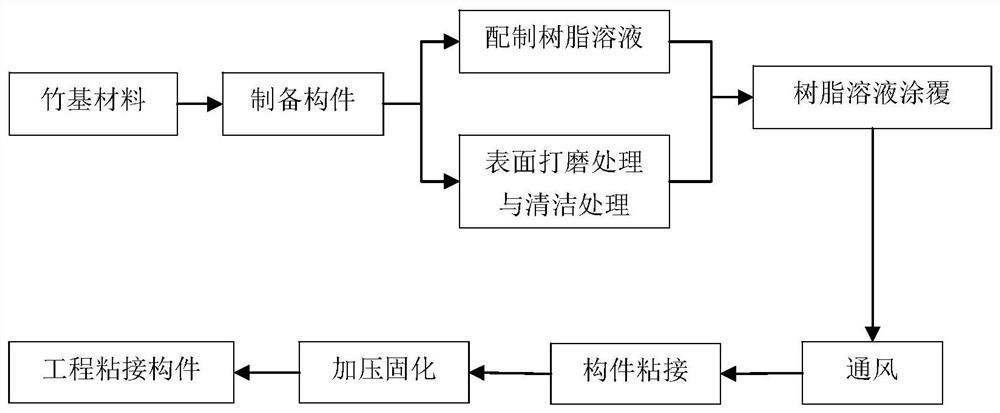

[0060] Such as figure 2 As shown, a surface treatment method for enhancing the bonding performance of epoxy resin glued joints is used to treat bamboo-based materials. Before coating epoxy resin glue, the resin solution is coated (can be dipped , brushing or spraying) on the bonding interface of the bamboo-based material, and then placed in a ventilated place to stand for 2 to 4 hours, volatilize the acetone in the resin solution, and then coat the epoxy resin glue on the The bonding interface is bonded, and then pressurized and solidified to obtain an epoxy resin bonded joint with enhanced bonding performance.

[0061] Specifically, the surface treatment method may include the following embodiments:

[0062] (1) Preparation of resin solution: the resin solution is formed by mixing resin and acetone, and the resin accounts for 5% to 20% (preferably 10%) of the total mass of the resin solution, and the rest is acetone. The resin in the resin solution is the same as the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com