Rhizoma bletillae glue wallpaper powder and preparation method thereof

A white glue and paper powder technology, applied in the direction of adhesives, starch adhesives, adhesive types, etc., can solve the problems of affecting product performance, slow formaldehyde release, and easy moldy products, so as to achieve long service life and reduce water absorption High efficiency and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

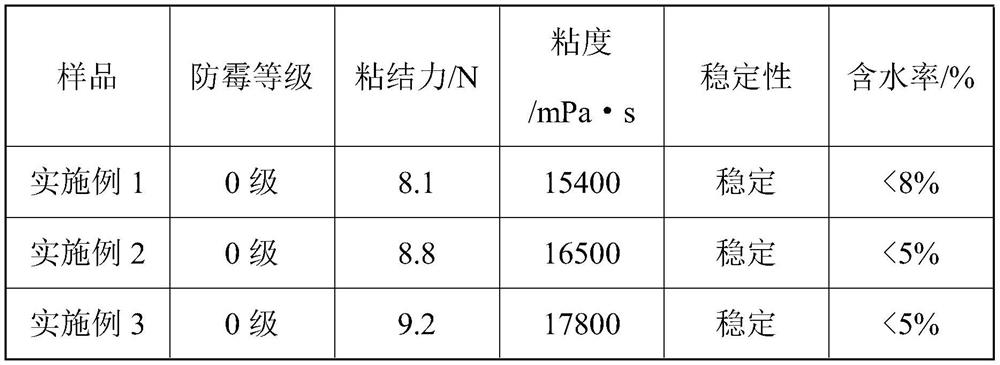

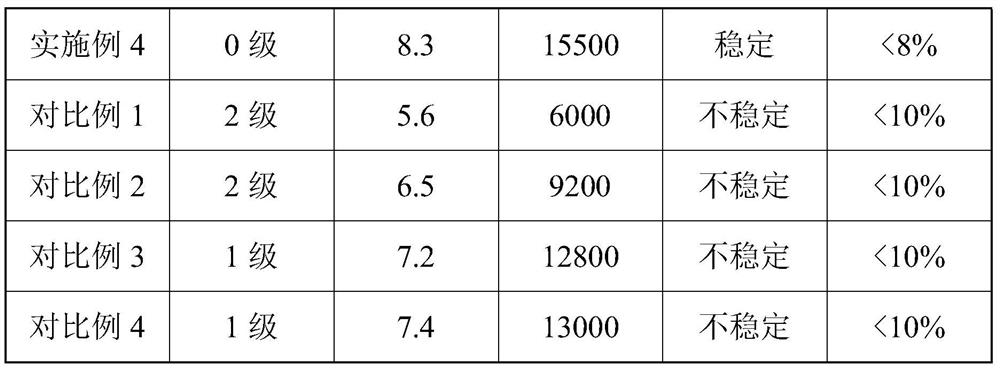

Examples

Embodiment 1

[0040] This embodiment provides a kind of white glue wallpaper powder, and raw material component comprises:

[0041] Starch, 22 parts by weight;

[0042] Baijijiao superfine powder, 15 parts by weight;

[0043] Xanthan gum, 1 part by weight;

[0044] Sodium hydroxymethylcellulose, 3 parts by weight;

[0045] The filler is a mixture of nano titanium dioxide with a particle size of 40nm and micron titanium dioxide with a particle size of 2 μm in a mass ratio of 1:2, 1 part by weight;

[0046] Borax, 1 part by weight.

[0047] Described Baijijiao superfine powder adopts following method to prepare:

[0048] (S1) get bletilla tuber, after drying and crushing, obtain bletilla fine powder with a particle diameter of 80nm, add 2 times the mass and volume concentration of 80% ethanol to the bletilla fine powder and carry out reflux extraction under heating conditions, extract Filter after completion to obtain medicinal residues;

[0049] (S2) After the ethanol contained in the ...

Embodiment 2

[0060] This embodiment provides a kind of white glue wallpaper powder, and raw material component comprises:

[0061] Starch, 28 parts by weight;

[0062] Baijijiao superfine powder, 5 parts by weight;

[0063] Xanthan gum, 3 parts by weight;

[0064] Sodium hydroxymethylcellulose, 1 part by weight;

[0065] The filler is a mixture of nano titanium dioxide with a particle size of 60nm and micron titanium dioxide with a particle size of 4 μm in a mass ratio of 2:1, 3 parts by weight;

[0066] Borax, 0.1 parts by weight.

[0067] Described starch adopts following method to carry out pretreatment:

[0068] (a) taking starch and dispersing it in pH 6 phosphate buffer, the ratio of the mass of starch to phosphate buffer is 1:2;

[0069] Thoroughly stir and mix at 80°C for 1 hour at a speed of 80rpm to obtain a paste;

[0070] (b) Cool the paste to 40°C, adjust the pH to 2, add silicone oil, the ratio of the amount of silicone oil added to the mass of starch is 1:4; keep the t...

Embodiment 3

[0084] This embodiment provides a kind of white glue wallpaper powder, and raw material component comprises:

[0085] Starch, 25 parts by weight;

[0086] Baijijiao superfine powder, 10 parts by weight;

[0087] Xanthan gum, 2 parts by weight;

[0088] Sodium hydroxymethylcellulose, 2 parts by weight;

[0089] The filler is a mixture of nano titanium dioxide with a particle size of 50nm and micron titanium dioxide with a particle size of 3 μm in a mass ratio of 1:1, 2 parts by weight;

[0090] Borax, 0.5 parts by weight.

[0091] Described starch adopts following method to carry out pretreatment:

[0092] (a) getting starch and dispersing it in pH 7 phosphate buffer solution, the mass ratio of the starch and phosphate buffer solution is 1:4;

[0093] Fully stir and mix at 100°C at a speed of 120rpm for 0.5h to obtain a paste;

[0094] (b) Cool the paste to 60°C, adjust the pH to 3, add silicone oil, the ratio of the amount of silicone oil added to the mass of starch is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com