A kind of multi-phase low-temperature co-fired ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics and multiphase ceramics, which is applied in the field of electronic materials, can solve the problems of difficult to achieve mass application, difficult to control formulation stability and glass properties, and achieve the effects of easy control, lower sintering temperature, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

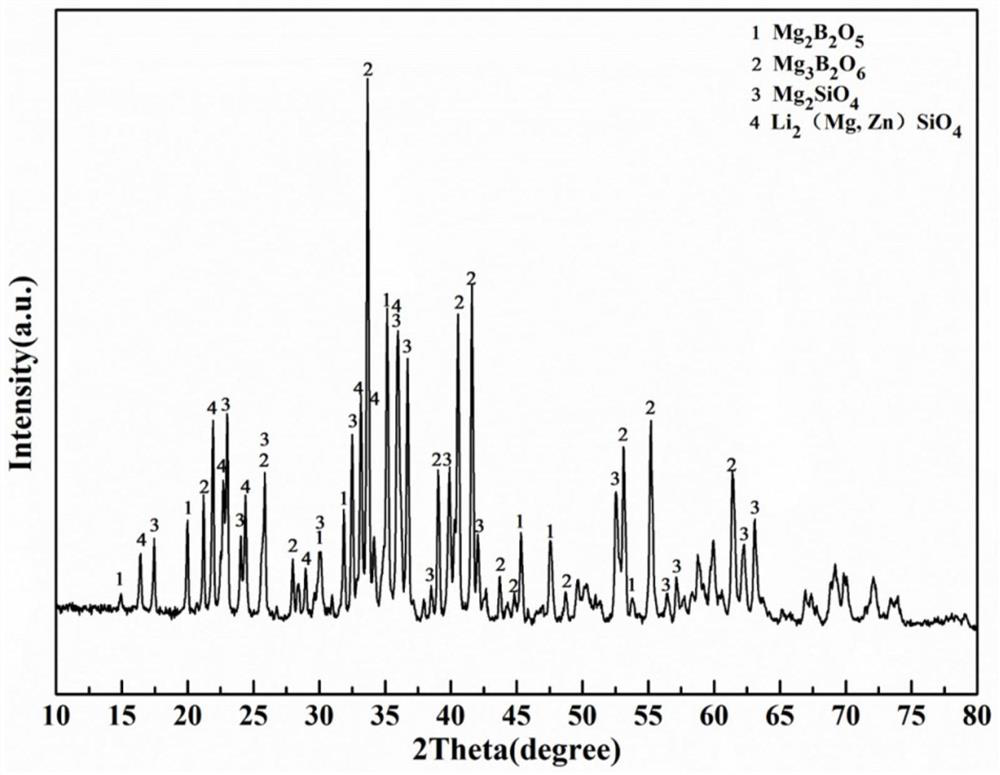

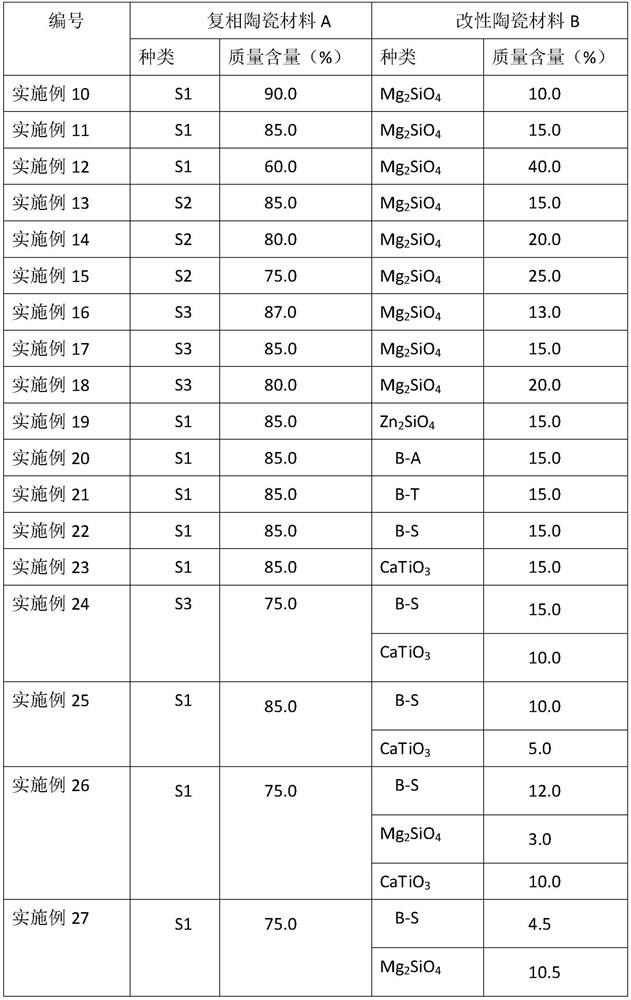

[0030] Embodiment 1-3 is the preparation of multiphase ceramic A

[0031] (1) according to the raw material ratio in table 1, take by weighing Li 2 CO 3 , MgO, ZnO, H 3 BO 3 , SiO 2 Raw material powder, according to the mass ratio of powder, zirconia balls, and absolute ethanol is 1:5:2, put into a nylon tank, use anhydrous ethanol as a solvent, mix it with a roller mill for 12 hours, take it out and dry it at 80 °C 12h, pass through a 60-mesh sieve, then put into a crucible and calcined in an atmosphere of 800°C for 2 hours to synthesize composite ceramic material A.

[0032] Table 1

[0033] Numbering material code Li 2 CO 3 (%)

Embodiment 4-9

[0035] (2) Preparation of modified ceramic material B:

Embodiment 4

[0037] Mg 2 SiO 4 Preparation: Weigh the raw materials MgO and SiO according to the stoichiometric ratio of 2:1 2 Mixing, according to the mass ratio of powder, zirconia balls and anhydrous ethanol to 1:5:2, add it into a nylon tank, use anhydrous ethanol as a solvent, mix the ball and mill for 12h, take it out and dry it at 80°C for 12h, over 60 mesh sieve, then loaded into an alumina crucible, pre-fired at 1300 ℃ for 3 hours in the atmosphere to synthesize Mg 2 SiO 4 ceramic powder;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com