A kind of sea velvet fucoidan sulfate and its application in the preparation of medicines and functional products for preventing and treating leukopenia

A technology of sea antler fucoidan sulfate and leukopenia, which is applied in the field of marine medicine, can solve the problems of high price and unsatisfactory curative effect, and achieve the effects of promoting proliferation, increasing the number of nucleated cells in bone marrow, and improving the formation of bone marrow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

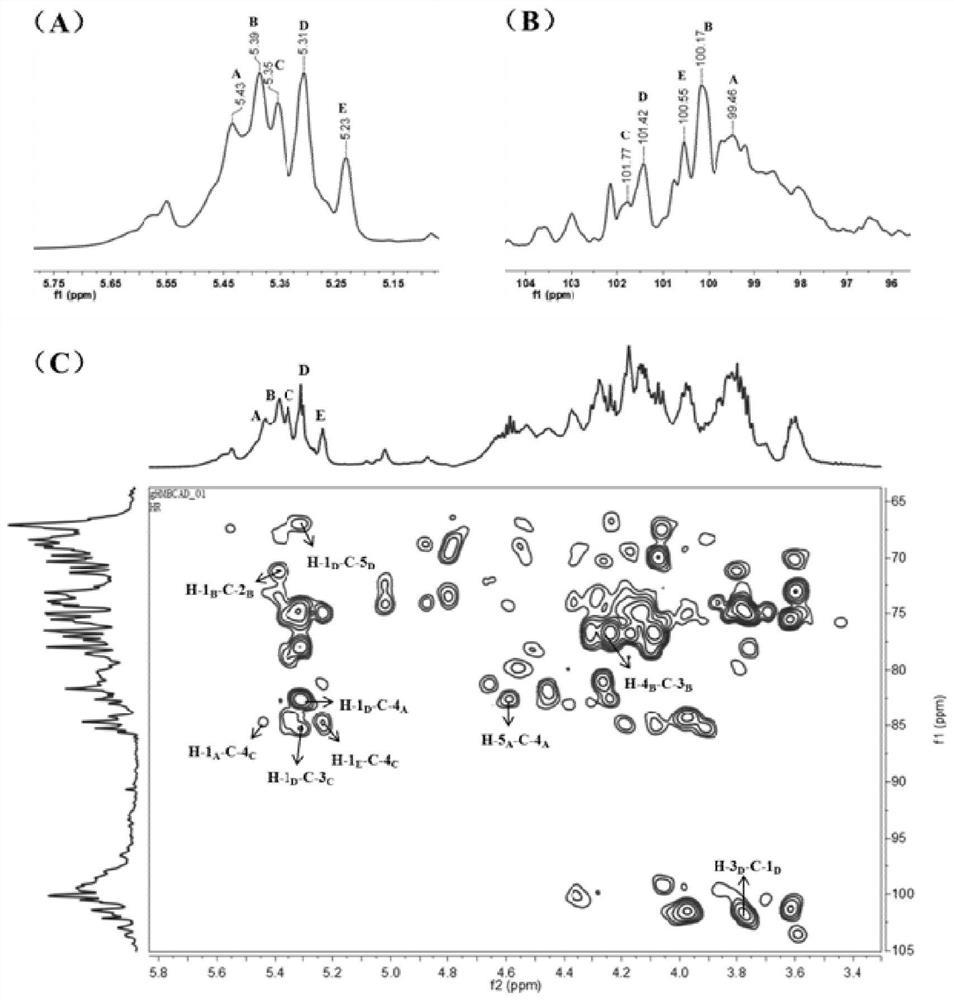

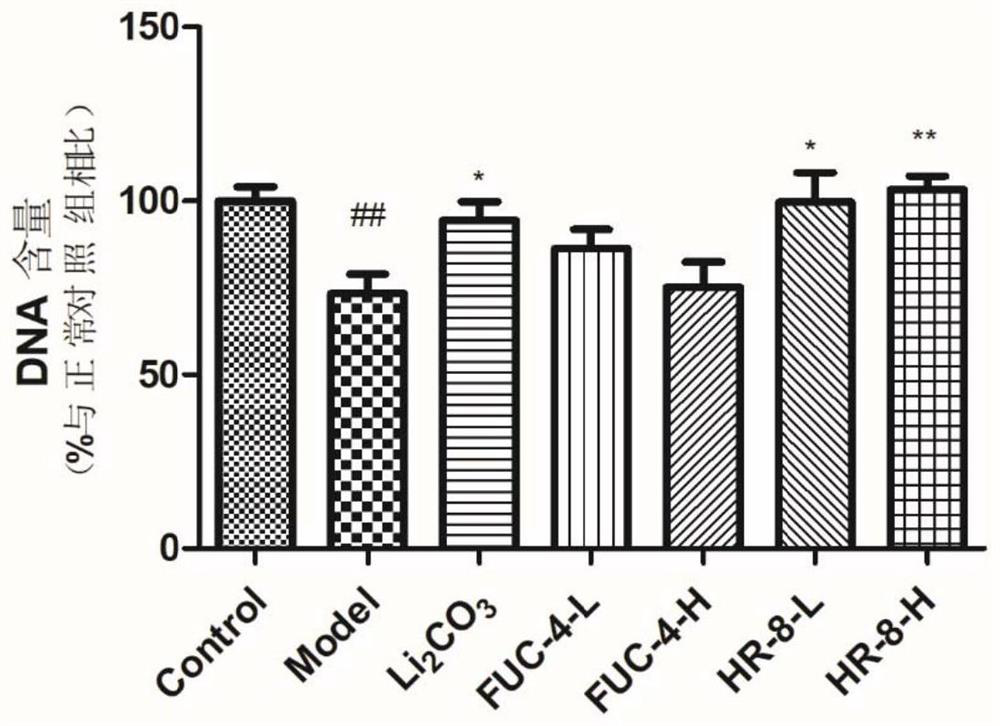

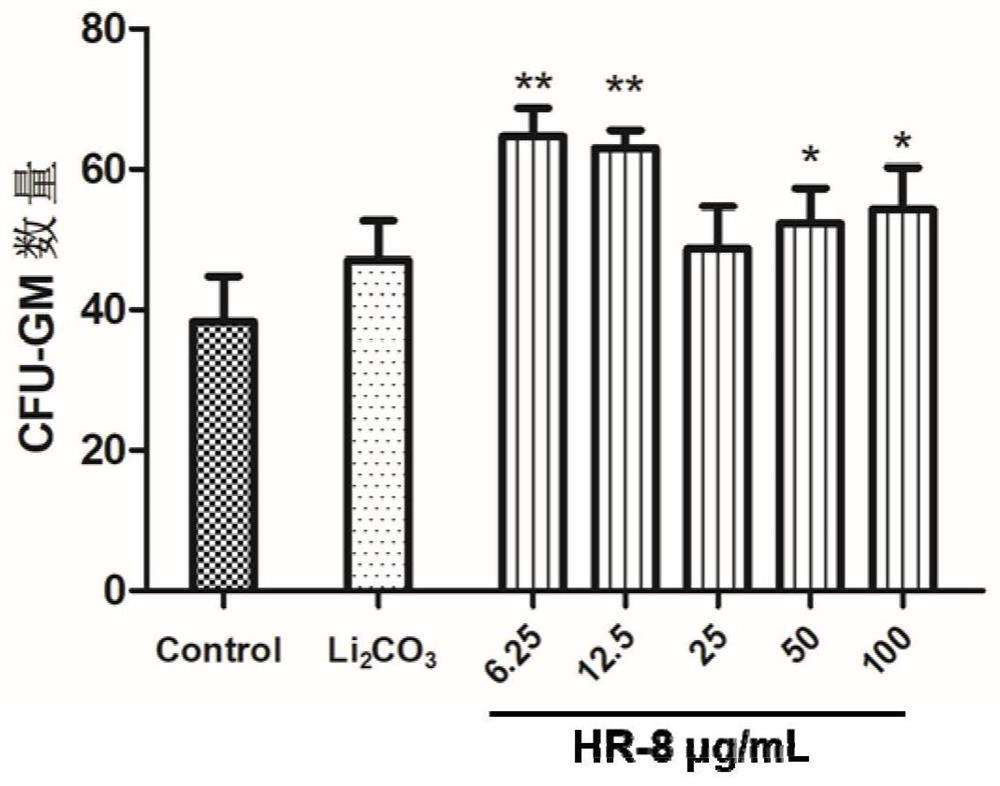

[0038] Embodiment 1, the preparation of sea velvet fucoidan sulfate (method 1)

[0039] Wash the sea velvet, dry it, crush it, and pass it through a 20-mesh sieve. Accurately weigh 200g of algal powder, add 2L of 0.05mol / L dilute hydrochloric acid according to the ratio of material to liquid 1:10, and extract at 60°C for 4h. The extract was centrifuged at 4000 rpm for 15 min, the supernatant was collected, and the algal residue was removed. The extraction supernatant was concentrated under reduced pressure to 1 / 5 of the total volume, and 95% ethanol was added to it until the ethanol concentration reached 20%, and the mixture was allowed to stand overnight to obtain a precipitated fraction HR-1. Continue adding 95% ethanol to the supernatant until the final concentration is 70%, let stand overnight, and dry the obtained precipitate in a 50° C. oven to obtain crude polysaccharide. The crude polysaccharide was prepared into an aqueous solution with a concentration of 2%, and af...

Embodiment 2

[0040] Embodiment 2, the preparation of sea velvet fucoidan sulfate (method 2)

[0041] Wash the sea velvet, dry it, crush it, and pass it through a 20-mesh sieve. Accurately weigh 200g of algal powder, add 0.1mol / L CaCl according to the ratio of material to liquid 1:20 22L, extracted at 70°C for 4h. The extract was centrifuged at 4000 rpm for 15 min, the supernatant was collected, and the algal residue was removed. The extraction supernatant was concentrated under reduced pressure to 1 / 5 of the total volume, and 95% ethanol was added thereto until the ethanol concentration reached 20%, and the mixture was allowed to stand overnight to remove the precipitate. Continue adding 95% ethanol to the supernatant until the final concentration is 70%, let stand overnight, and dry the obtained precipitate in a 50° C. oven to obtain crude polysaccharide. The crude polysaccharide was prepared into an aqueous solution with a concentration of 2%, which was classified by a 30kDa ultrafilt...

Embodiment 3

[0042] Embodiment 3, the preparation of sea velvet fucoidan sulfate (method 3)

[0043] Wash the sea velvet, dry it, crush it, and pass it through a 20-mesh sieve. Accurately weigh 200g of algae powder, add 2L of 0.2mol / L calcium chloride-0.05mol / L dilute hydrochloric acid mixed solution according to the ratio of material to liquid 1:10, and extract at 50°C for 4h. The extract was centrifuged at 4000 rpm for 15 min, the supernatant was collected, and the algal residue was removed. The extraction supernatant was concentrated under reduced pressure to 1 / 5 of the total volume, and 95% ethanol was added thereto until the ethanol concentration reached 30%, and the mixture was allowed to stand overnight to remove the precipitate. Continue adding 95% ethanol to the supernatant until the final concentration is 80%, let stand overnight, and dry the obtained precipitate in a 50° C. oven to obtain crude polysaccharide. The crude polysaccharide was passed through an anion exchange chrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com