Preparation method of multilayer dielectric film rectangular diffraction grating with high damage threshold

A technology with high damage threshold and multi-layer media, applied in the direction of diffraction grating, optomechanical equipment, photoplate process of patterned surface, etc., can solve the problems of difficult preparation, achieve low cost, increase damage threshold, and avoid absorption defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

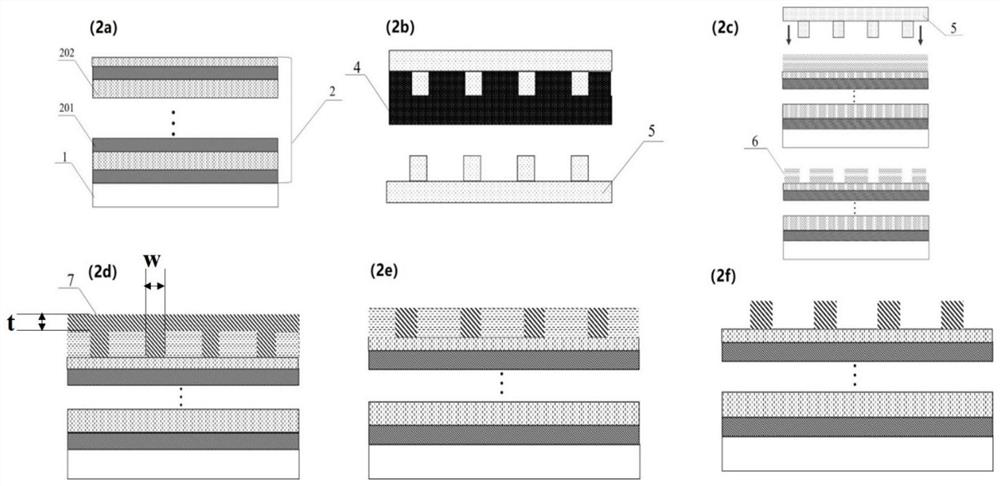

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

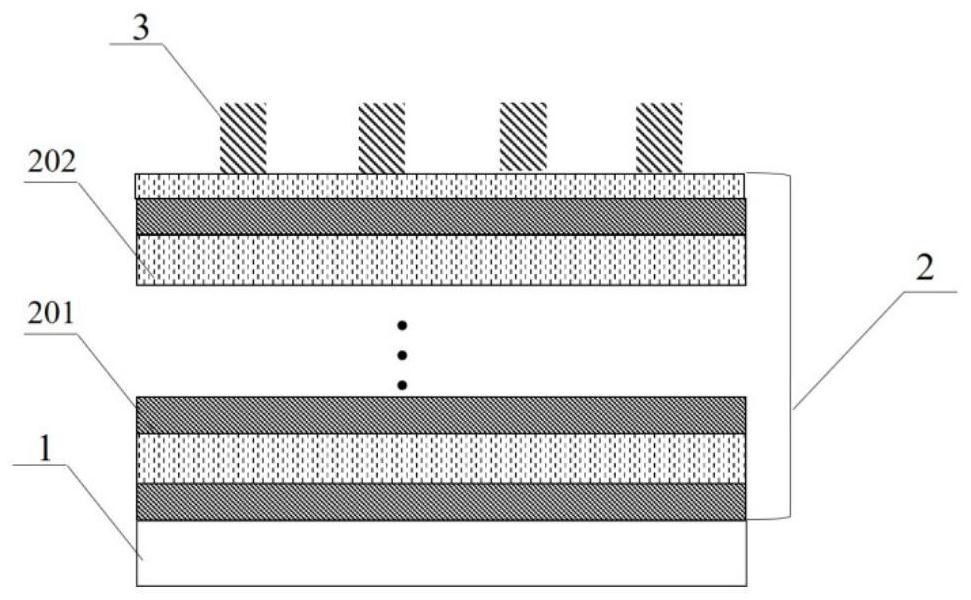

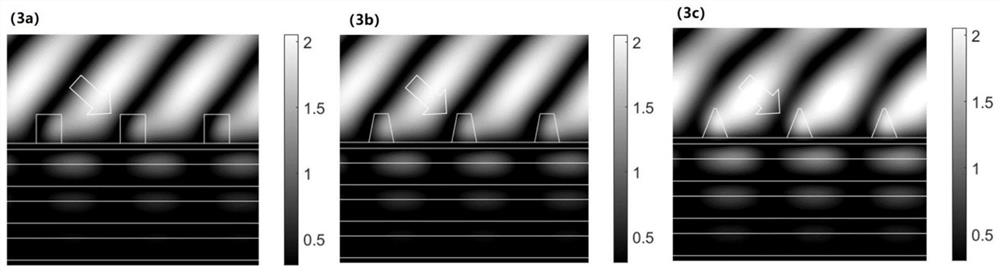

[0041] Such as Figure 7 As shown, this embodiment provides a method for preparing a multilayer dielectric rectangular diffraction grating with a high damage threshold. The multilayer dielectric rectangular diffraction grating to be prepared includes a substrate, a dielectric multilayer film, and a grating structure. The preparation method includes The following steps:

[0042] S1. Plating multi-layer dielectric film.

[0043] The multi-layer dielectric film 2 is plated on the clean substrate by ion beam assisted electron beam evaporation coating method. The multilayer film is char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com