Resin composition and preparation method and application thereof

A resin composition and resin technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of increasing production costs, difficult to control requirements, etc., to achieve accurate measurement, improve product quality, improve Effect of Glass Transition Temperature and Heat Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

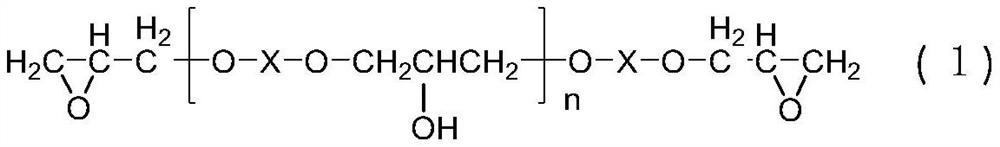

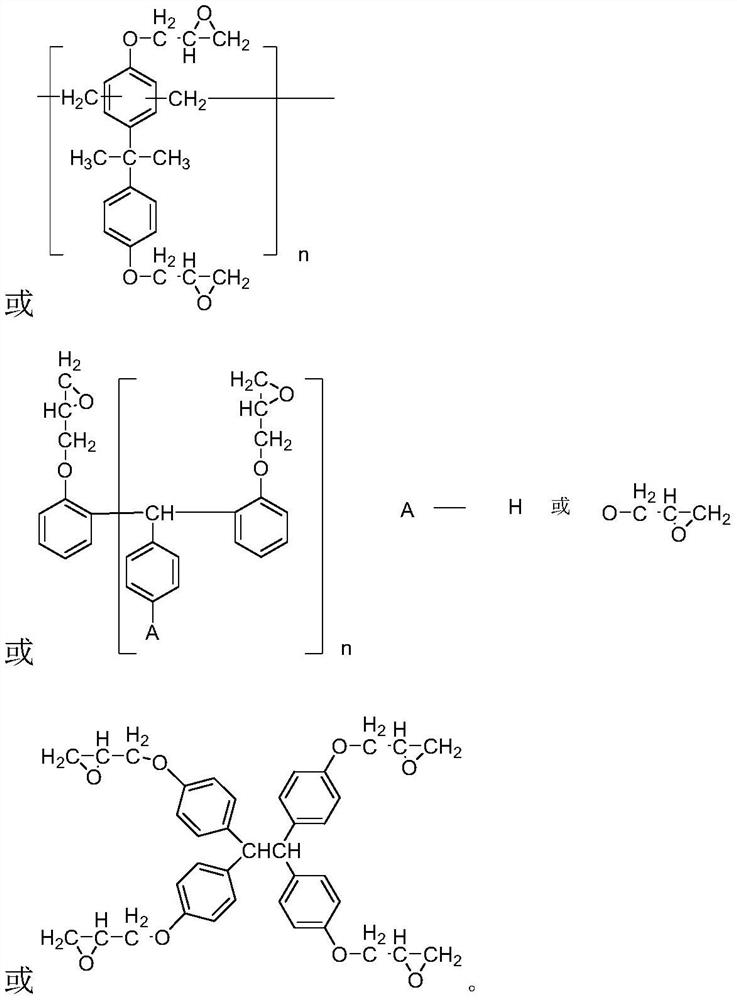

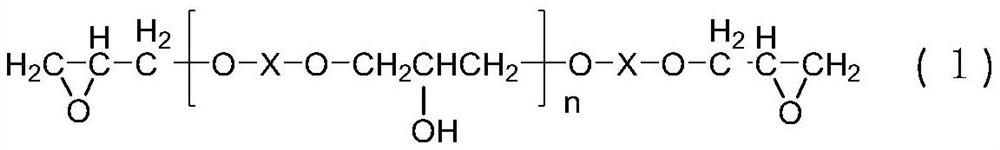

[0067]Bisphenol A type epoxy resin: 20g, the formula is (1), in the formula X is

[0068]Phenol formaldehyde epoxy resin: 5g,

[0069]20% epoxy resin: 40g,

[0070]BPA benzoxazine resin: 28g,

[0071]Tetrachromobisphenol A: 20g,

[0072]Linear phenolic resin: 15g,

[0073]Solvent: Acetone: 20g, methanol: 5g

[0074]Under nitrogen protection, the bisphenol A-type epoxy resin was added to 100 ° C to start melting, adding bromide, BPA benzoxazine resin, tetrabromide bisphenol A, phenol formaldehyde epoxy resin and line type Phenolic resin, mixing is uniform, then adding acetone and methanol to obtain a resin composition to obtain a resin composition.

[0075]Take 125 g of the resin composition of Example 1, 5% mica, SiO2Filler, add 20 g of acetone and 10 gpm (propylene glycol methyl ether) and 0.04 g of methylimidazole (cured accelerator), and the curing time of the stirring 30 minutes is controlled between 160 to 260s.

[0076]The 7628 glass cloth was impregnated with the gum liquid, baked at 170 ° C for a semi...

Embodiment 2

[0080]Bisphenol A epoxy resin: 40g, its general formula (1), in the formula X is

[0081]Bromine-containing epoxy resin: 10g, structural formula

[0082]

[0083]Isocyanate modified epoxy resin: 5g

[0084]Topphenolice phenolic resin KB802: 2G,

[0085]CN: 15G

[0086]Tetrachromobisphenol A (TBBA): 28g

[0087]Acenone (ACE): 20g

[0088]Tolue (Tol): 5g

[0089]Under nitrogen protection, the bisphenol A epoxy resin was added to 120 ° C to add a bromine-containing epoxy resin, and the isocyanate modified epoxy resin was stirred, and Ace and Tol were added, and the Kb802, Cn and TBBA were added, and the dissolution was mixed. The resin composition is baked.

[0090]125 g of the resin composition of 125 g of Example 2, add 8 wt% filler, 20 g of propanol and 10 g of propylene glycol methyl ether and 0.02 g of 2 methylimidazole and 0.02 g of 2-methyl-4 ethylimidazole, stirred for 30 minutes glue The curing time is controlled between 160 and 260s.

[0091]The filler is an uncertainty of silica, talc, and mica.

[0092]The 76...

Embodiment 3

[0096]Bisphenol A epoxy resin: 20g, its general formula (1), in the formula X is

[0097]Contaminated epoxy resin: 20g, which is (1), in the formula

[0098]MDI modified epoxy resin: 20g,

[0099]Bisphenol A-formaldehyde resin: 15g

[0100]Tetophenolic ethane epoxy resin: 5g

[0101]Tetrachromobisphenol A (TBBA): 20g

[0102]DPM benzoxazine: 15g

[0103]Acetone: 20g

[0104]Glycol methyl ether: 5g

[0105]Under nitrogen protection, the bisphenol A-type epoxy resin, a bromine-containing epoxy resin, MDI modified epoxy resin is heated, and 10 g of acetone is dissolved uniform, then 10 g of acetone, 5 g of propylene glycol methyl ether, uniform dissolved, Add bisphenol A-type formaldehyde resin and tetraromobisphenol A dissolution. After dissolving the resin described above, then the tetraphenol-based ethane epoxy resin was dissolved to give a resin composition solution.

[0106]125 g of the resin composition of Example 3, add 6 wt% filler, 20 g of acetate and 10 gpma and 0.02 g of 2-mi and 0.02 g of 2-pi, stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com