Preparation method of single-component transparent organic silicon sealant

A silicone, one-component technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of limited improvement, changing amine coupling agents, and need to improve, to ensure Curing speed, the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

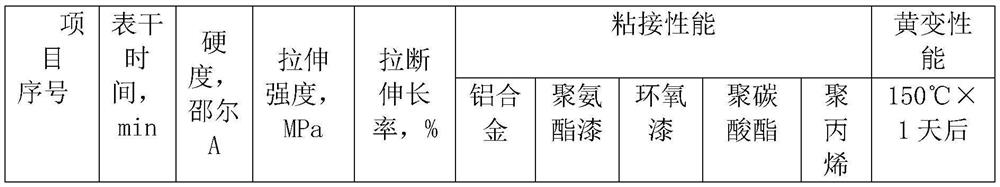

Examples

Embodiment 1

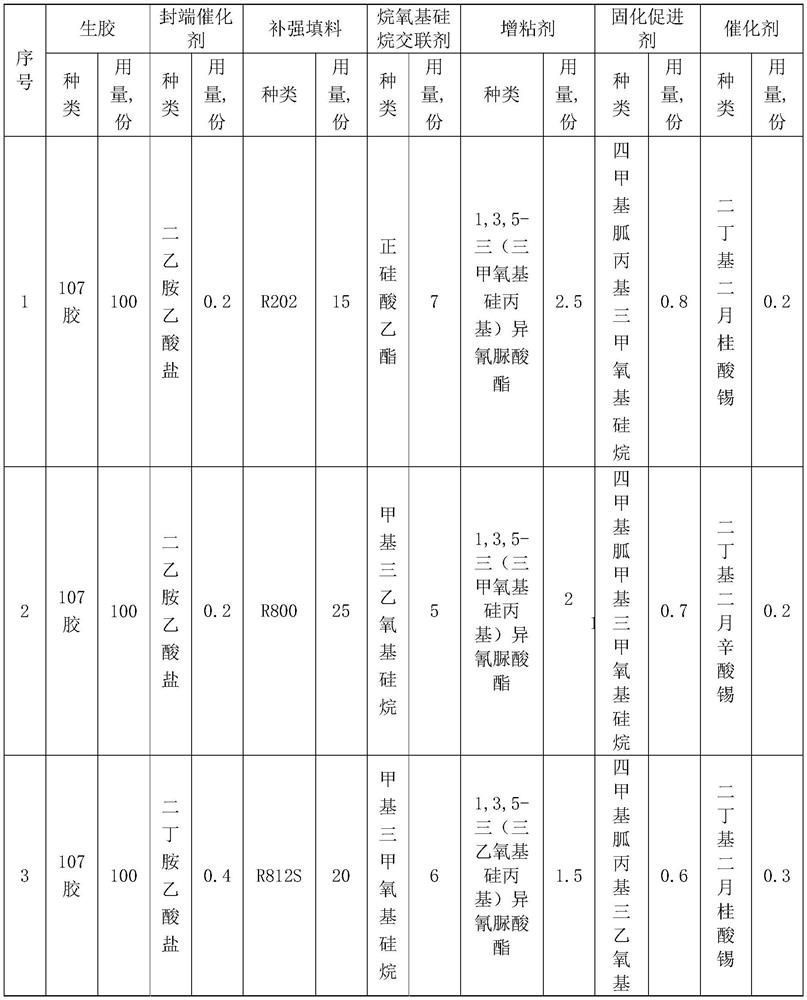

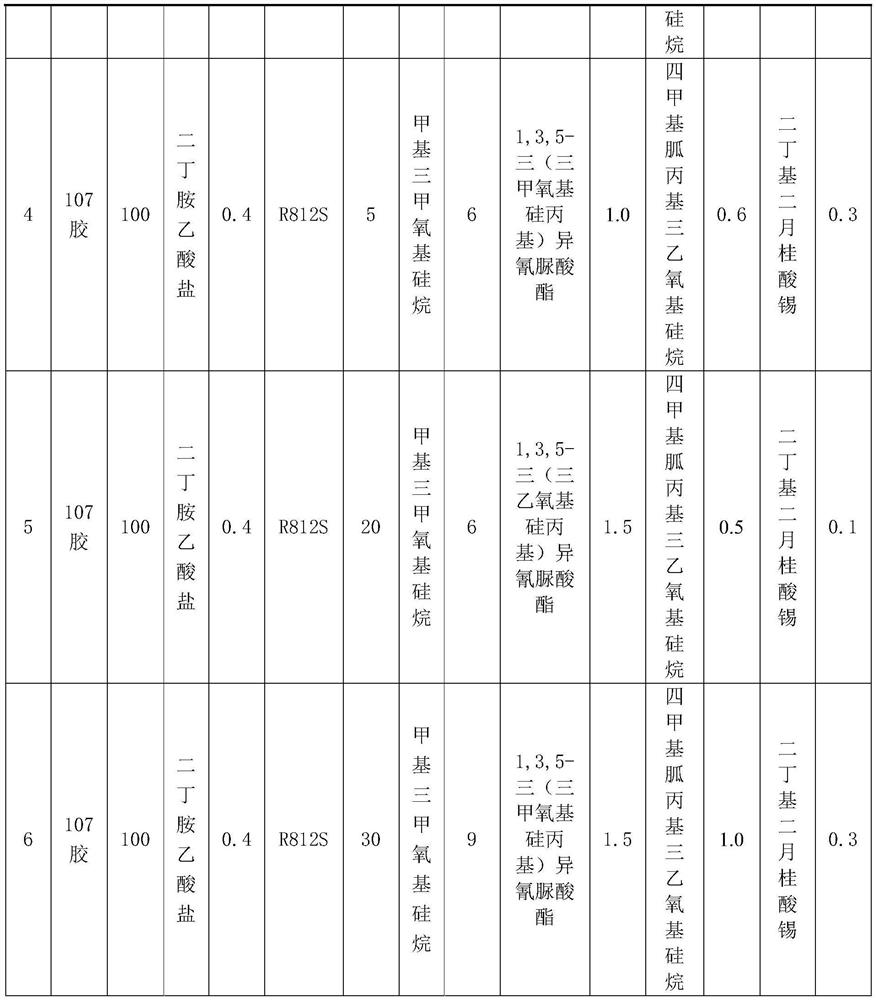

[0027] Embodiment 1, α, ω-dihydroxy polydimethylsiloxane, reinforcing filler, end-blocking catalyst, alkoxysilane crosslinking agent, tackifier, curing accelerator and organotin are used in the technical solution of the present invention Catalysts and their amounts are shown in Table 1.

[0028] The technical solution of the present invention will be described in detail below by taking the single-component transparent high-anti-yellowing dealcoholization type room temperature vulcanizing silicone sealant prepared with the components of No. 1 in Table 1 as an example. The method steps of preparation are as follows:

[0029] The preparation method of one-component transparent silicone sealant comprises the following steps:

[0030] Step 1. Obtain α, ω-dihydroxy polydimethylsiloxane, reinforcing filler, end-blocking catalyst, alkoxysilane crosslinking agent, tackifier, curing accelerator and organotin catalyst; the above-mentioned components The mass percentage is 100:5~30:0.2~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com