Flame-retardant non-woven fabric and preparation method thereof

A technology of flame retardant non-woven fabrics and non-woven fabrics, used in flame-retardant fibers, textiles and papermaking, fiber processing, etc. performance, the effect of stabilizing flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

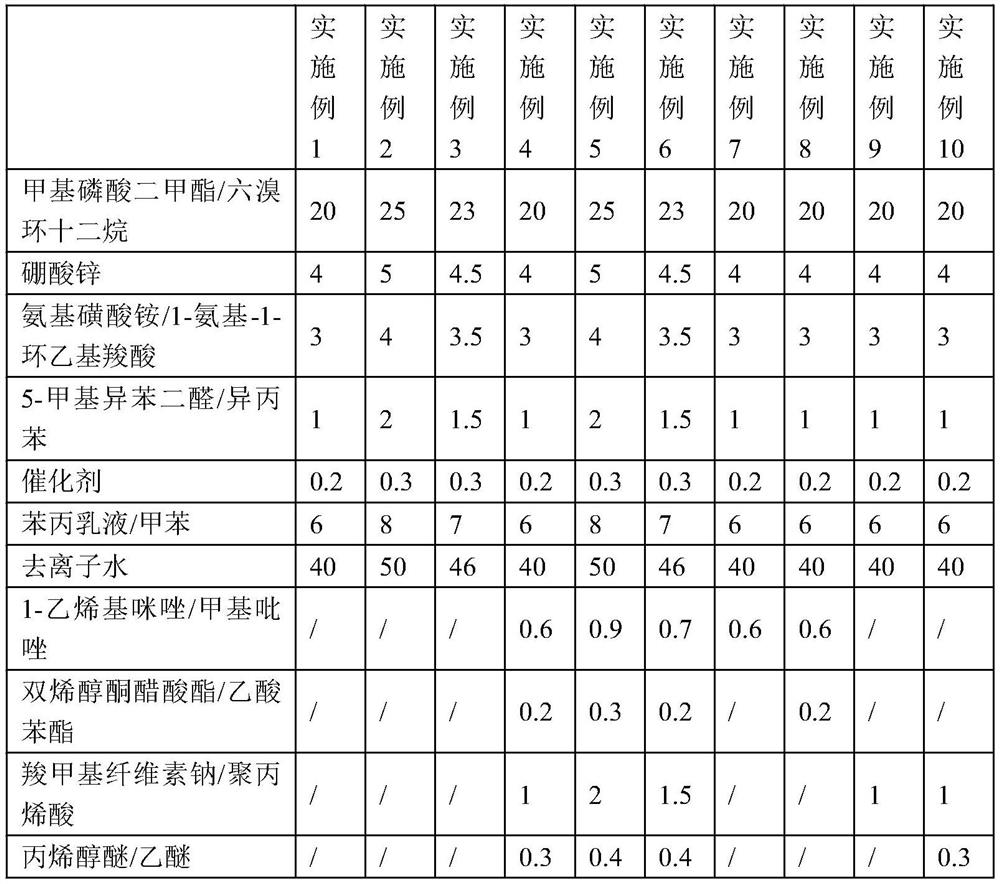

Embodiment 1

[0040] The application discloses a flame-retardant non-woven fabric and a preparation method thereof. The non-woven fabric is treated with a flame-retardant treatment agent. The preparation method includes the following steps:

[0041] S1. Preparation of flame retardant finishing agent; first mix styrene-acrylic emulsion and zinc borate evenly, then add dimethyl methyl phosphate, stir for 5 minutes; continue to add sodium sulfamate and catalyst thionyl chloride, and heat up to After 50°C, add 5-methylisophthalaldehyde, stir the polymer obtained after 30 minutes of reaction, finally add deionized water, and stir at 30°C for 50 minutes to obtain a flame retardant finishing agent;

[0042] S2. Flame-retardant finishing of non-woven fabrics; soak the non-woven fabrics in the flame-retardant finishing agent obtained in S1 and let it stand for 15 minutes; arrange the soaked non-woven fabrics between the two rubber rollers of the roller press, squeeze The excess liquid was removed by...

Embodiment 2

[0045] The application discloses a flame-retardant non-woven fabric and a preparation method thereof. The non-woven fabric is treated with a flame-retardant treatment agent. The preparation method includes the following steps:

[0046] S1. Preparation of flame retardant finishing agent; first mix styrene-acrylic emulsion and zinc borate evenly, then add dimethyl methyl phosphate, stir for 8 minutes; continue to add sodium sulfamate and catalyst thionyl chloride, and heat up to After 55°C, add 5-methylisophthalaldehyde, stir the polymer obtained after 40 minutes of reaction, finally add deionized water, and stir at 40°C for 60 minutes to obtain a flame retardant finishing agent;

[0047] S2. Flame-retardant finishing of non-woven fabrics; soak the non-woven fabrics in the flame-retardant finishing agent obtained in S1 and let it stand for 20 minutes; arrange the soaked non-woven fabrics between the two rubber rollers of the roller press, squeeze The excess liquid was removed by...

Embodiment 3

[0050] The application discloses a flame-retardant non-woven fabric and a preparation method thereof. The non-woven fabric is treated with a flame-retardant treatment agent. The preparation method includes the following steps:

[0051] S1. Preparation of flame retardant finishing agent; first mix styrene-acrylic emulsion and zinc borate evenly, then add dimethyl methyl phosphate, stir for 7 minutes; continue to add sodium sulfamate and catalyst thionyl chloride, and heat up to After 52°C, add 5-methylisophthalaldehyde, stir and react for 35 minutes to obtain the polymer, finally add deionized water, and stir at 35°C for 55 minutes to obtain a flame retardant finishing agent;

[0052] S2. Flame-retardant finishing of non-woven fabrics; soak the non-woven fabrics in the flame-retardant finishing agent obtained in S1 and let it stand for 18 minutes; arrange the soaked non-woven fabrics between the two rubber rollers of the roller press, squeeze The excess liquid was removed by pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com