A method for preparing the back of a perc single crystal double-sided solar cell

A technology on the back of solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of silicon substrate damage, increase laser energy consumption, affect the electrical performance of solar cells, etc., achieve the effect of reducing recombination centers and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

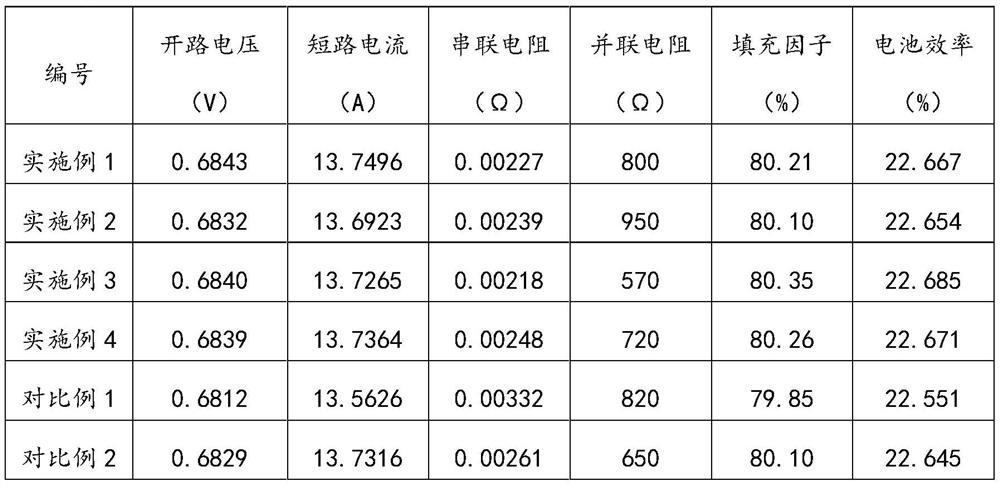

Embodiment 1

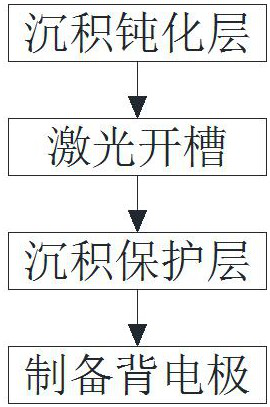

[0025] like figure 1 As shown, the method for preparing the back surface of the PERC single crystal double-sided solar cell of Example 1 includes the following steps:

[0026] (1) Deposition of passivation layer: ALD (atomic layer deposition) method is used to deposit an aluminum oxide film on the back of the polished silicon substrate. The thickness of the aluminum oxide film is 6nm, the refractive index is 1.65, the deposition temperature is 300°C, and the deposition time is 300°C. is 35s, and the deposition pressure is 1000pa;

[0027] (2) Laser grooving: use a low-energy laser to irradiate the aluminum oxide film on the back of the silicon substrate to form a grooved area on the surface of the aluminum oxide to expose the silicon substrate in the grooved area, where the laser power is 10W and the laser frequency is 1200kHz , the laser speed is 35000m / s, and the laser spot diameter is 25um;

[0028] (3) Deposition of protective layer: use PECVD (plasma vapor deposition) m...

Embodiment 2

[0031] The method for preparing the backside of the PERC single crystal double-sided solar cell of Example 2 is based on Example 1, with the difference that the laser speed in step (2) is increased, the laser power is reduced, and the laser spot diameter is reduced, that is, the following steps are included:

[0032] (1) Deposition of passivation layer: ALD (atomic layer deposition) method is used to deposit an aluminum oxide film on the back of the polished silicon substrate. The thickness of the aluminum oxide film is 6nm, the refractive index is 1.65, the deposition temperature is 300°C, and the deposition time is 300°C. is 35s, and the deposition pressure is 1000pa;

[0033] (2) Laser grooving: use a low-energy laser to irradiate the aluminum oxide film on the back of the above silicon substrate, form a grooved area on the surface of the aluminum oxide, and expose the silicon substrate in the grooved area, where the laser power is 8W and the laser frequency is 1200kHz , th...

Embodiment 3

[0037] The method for preparing the back surface of the PERC single crystal double-sided solar cell in Example 3 is based on Example 1, except that the deposition time in step (3) is extended to increase the thickness of the silicon nitride film, that is, the following steps are included:

[0038] (1) Deposition of passivation layer: ALD (atomic layer deposition) method is used to deposit an aluminum oxide film on the back of the polished silicon substrate. The thickness of the aluminum oxide film is 6nm, the refractive index is 1.65, the deposition temperature is 300°C, and the deposition time is 300°C. is 35s, and the deposition pressure is 1000pa;

[0039] (2) Laser grooving: use a low-energy laser to irradiate the aluminum oxide film on the back of the silicon substrate to form a grooved area on the surface of the aluminum oxide to expose the silicon substrate in the grooved area, where the laser power is 10W and the laser frequency is 1200kHz , the laser speed is 35000m / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com