Preparation method of Xinnaoxin tablets

A heart-brain and centrifugal filtration technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve the problems of lycium barbarum decocting operation, low curative effect, long production cycle, etc. , to achieve the effect of improving the decoction efficiency, reducing the extraction yield and increasing the production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

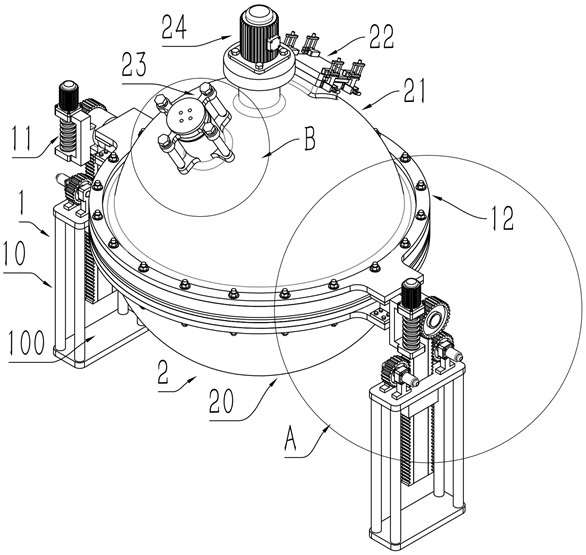

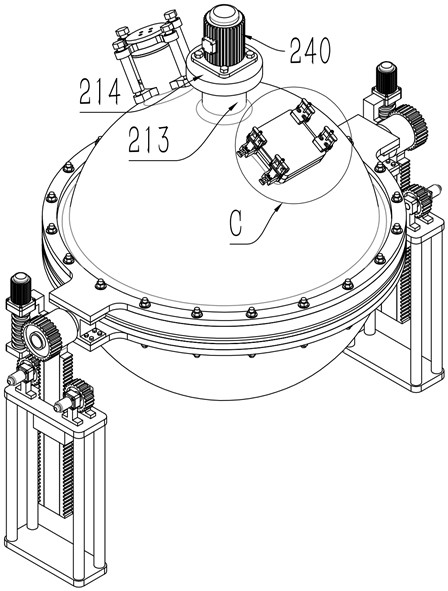

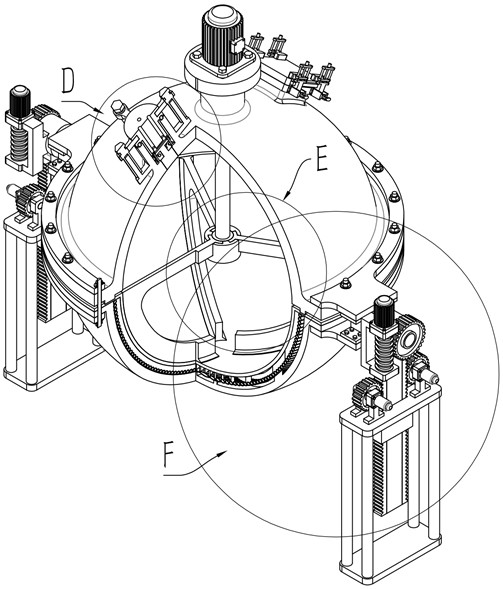

Image

Examples

Embodiment 1

[0110] (1) Take 800g Rhodiola rosea, add 5 times the amount of 70% ethanol to reflux and extract twice, the first time is 3 hours, the second time is 2 hours, combine the extracts, recover the ethanol and use it for later use;

[0111] (2) Take 400g wolfberry, add 5 times the amount of water to decoct twice, combine the decoction, each time for 2 hours, combine the decoction, and the filtrate for later use;

[0112] (3) 130g of seabuckthorn fresh pulp is mixed with the above-mentioned alcohol extract and water extract, concentrated to 50°C, and a clear paste with a relative density of 1.05~1.10;

[0113] (4) Centrifuge the above clear paste at 2000r / min for 5 minutes, add β-cyclodextrin and appropriate amount of starch accounting for 8% of the clear paste, heat and mix, and spray dry. The spray drying parameters are: air inlet temperature 160°C, The air outlet temperature is 75-85°C, the atomization is 320Hz for atomization, the liquid inlet speed is 10-20Hz, and the heating k...

Embodiment 2

[0143] (1) Take 1200g of Rhodiola rosea, add 15 times the amount of 70% ethanol to reflux and extract twice, the first time is 3 hours, the second time is 2 hours, combine the extracts, and recover the ethanol for later use;

[0144] (2) Take 600 g of wolfberry, add 10 times the amount of water to decoct twice, combine the decoction for 2 hours each time, combine the decoction, and use the filtrate for later use. decoction operation;

[0145] (3) Mix 150g of seabuckthorn fresh pulp with the above-mentioned alcohol extract and water extract, concentrate to 50°C, and make a clear paste with a relative density of 1.05~1.10;

[0146] (4) Centrifuge the clear paste at 4000r / min for 20 minutes, add β-cyclodextrin and an appropriate amount of starch accounting for 30% of the clear paste, heat and mix, and spray dry. The spray drying parameters are: inlet air temperature 160°C, outlet air temperature The air temperature is 75-85℃, the atomization is 320Hz for atomization, the liquid ...

Embodiment 3

[0149] As a preferred embodiment of this application,

[0150] (1) Take 1000g of Rhodiola rosea, add 10 times the amount of 70% ethanol to reflux and extract twice, the first time is 3 hours, the second time is 2 hours, combine the extracts, and recover the ethanol for later use;

[0151] (2) Take 500 g of wolfberry, add 8 times the amount of water to decoct twice, combine the decoction for 2 hours each time, combine the decoction, and use the filtrate for later use. decoction operation;

[0152] (3) Mix 140g of seabuckthorn fresh pulp with the above-mentioned alcohol extract and water extract, concentrate to 50°C, and make a clear paste with a relative density of 1.05~1.10;

[0153] (4) Centrifuge the clear paste at 3000r / min for 10 minutes, add β-cyclodextrin and appropriate amount of starch accounting for 15% of the clear paste, heat and mix, and spray dry. The spray drying parameters are: inlet air temperature 160°C, outlet air temperature The air temperature is 75-85℃, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com