Composite material of bimetallic oxide quantum dots and carbon nitride nano sheets as well as preparation method and application thereof

A technology of double metal oxides and composite materials, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve the problems of poor semiconductor charge separation, slow transport, and unsatisfactory improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

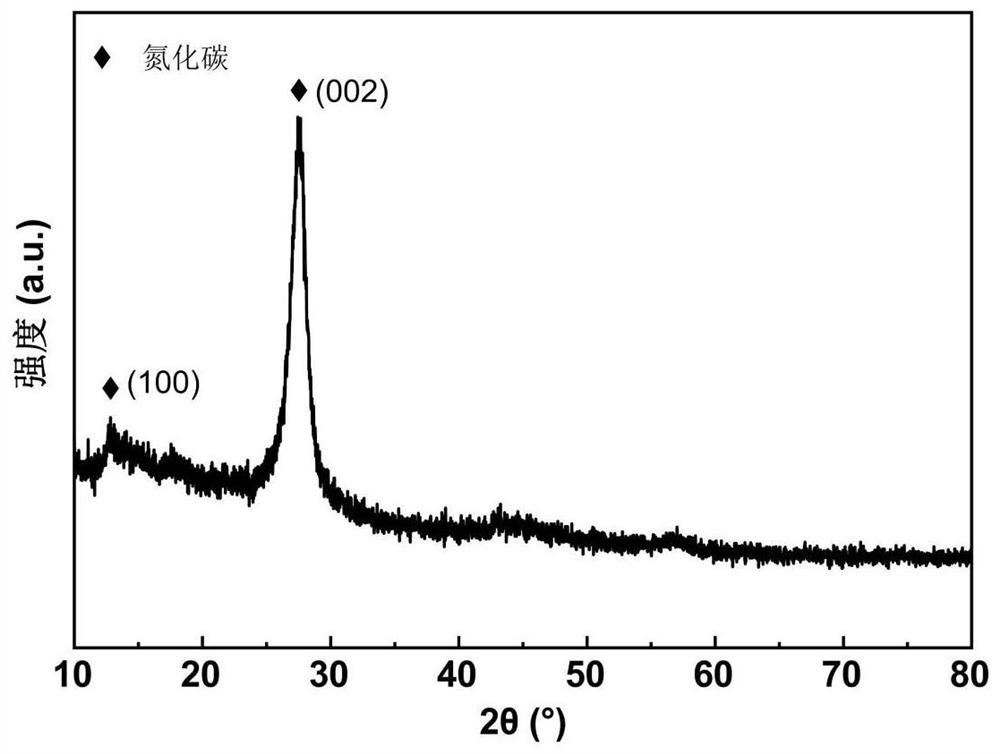

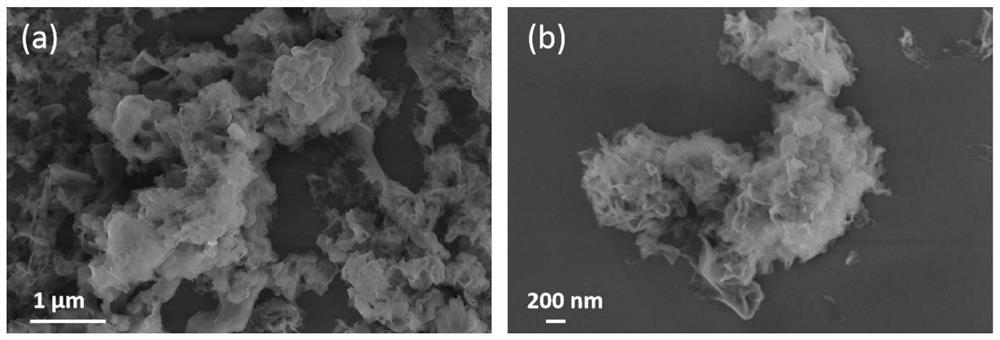

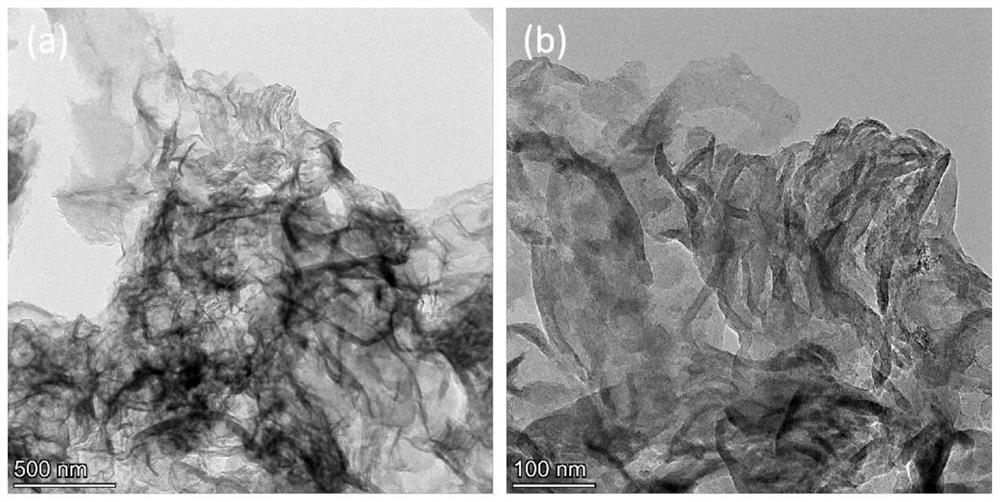

[0035] A composite material of double metal oxide quantum dots and carbon nitride nanosheets, comprising

[0036] continuous phase carbon nitride nanosheets; and

[0037] Disperse phase copper oxide quantum dots and iron oxide quantum dots.

[0038] Wherein, the molar ratio of the copper oxide quantum dots and iron oxide quantum dots is 7:3; the average particle diameter of the copper oxide quantum dots and iron oxide quantum dots is 2.2nm.

[0039] The preparation method of the composite material of the above-mentioned double metal oxide quantum dots and carbon nitride nanosheets comprises the following steps:

[0040]S1. Add urea to a crucible with a lid, place it in a muffle furnace and heat it to 550°C at a rate of 2.5°C / min, as the first stage of heating, and keep it for 4h; then cool the obtained crude product and open the lid of the crucible , heating to 500°C at a rate of 5°C / min in a muffle furnace as the second stage of heating, keeping for 2h, and calcining the ob...

Embodiment 2

[0048] A composite material of double metal oxide quantum dots and carbon nitride nanosheets, comprising

[0049] continuous phase carbon nitride nanosheets; and

[0050] Disperse phase copper oxide quantum dots and iron oxide quantum dots.

[0051] Wherein, the molar ratio of the copper oxide quantum dots and iron oxide quantum dots is 5:5; the average particle size of the copper oxide quantum dots and iron oxide quantum dots is 2.4nm.

[0052] The preparation method of the composite material of the above-mentioned double metal oxide quantum dots and carbon nitride nanosheets comprises the following steps:

[0053] S1. Add urea to a crucible with a lid, place it in a muffle furnace and heat it to 540°C at a rate of 2.5°C / min, as the first stage of heating, and keep it for 4h; then cool the obtained crude product and open the lid of the crucible , heating to 520°C at a rate of 5°C / min in a muffle furnace as the second stage of heating, keeping for 2h, and calcining the obtai...

Embodiment 3

[0058] A composite material of double metal oxide quantum dots and carbon nitride nanosheets, comprising

[0059] continuous phase carbon nitride nanosheets; and

[0060] Disperse phase copper oxide quantum dots and iron oxide quantum dots.

[0061] Wherein, the molar ratio of the copper oxide quantum dots and iron oxide quantum dots is 3:7; the average particle size of the copper oxide quantum dots and iron oxide quantum dots is 2.5nm.

[0062] The preparation method of the composite material of the above-mentioned double metal oxide quantum dots and carbon nitride nanosheets comprises the following steps:

[0063] S1. Add urea to a crucible with a lid, place it in a muffle furnace and heat it to 530°C at a rate of 2.5°C / min, as the first stage of heating, and keep it for 4h; then cool the obtained crude product and open the lid of the crucible , heating to 510°C at a rate of 5°C / min in a muffle furnace as the second stage of heating, keeping for 2h, and calcining the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com