Preparation method of stable hollow calcium carbonate particles with controllable particle size

A technology of calcium carbonate and particle size, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of large amount of chemical additives, difficult to guarantee product purity, stability to be verified, etc., to achieve high average particle size and stability, production The effect of low cost and low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of the hollow calcium carbonate particle of stable, particle size controllable, comprises the steps:

[0035] (1) First prepare 400ml of sodium carbonate solution and calcium chloride solution with a concentration of 0.4mol / L respectively, add magnesium hydroxide crystal form control agent which is 5% of the mass of calcium carbonate after reaction to the calcium chloride solution, stir and mix Uniform;

[0036] (2) Control the temperature at 20°C and the stirring speed at 600rmb / min. Add the sodium carbonate solution to the calcium chloride through a peristaltic pump at a rate of 40ml / min. After the addition is complete, continue to stir for 5 minutes to obtain a suspension;

[0037] (3) After the reaction, add 95% ethanol to the suspension and store it for 2 hours, filter it, dehydrate it by pressure filtration, microwave dry it at 100°C for 2.5 hours, crush it, and classify it to obtain hollow calcium carbonate particles.

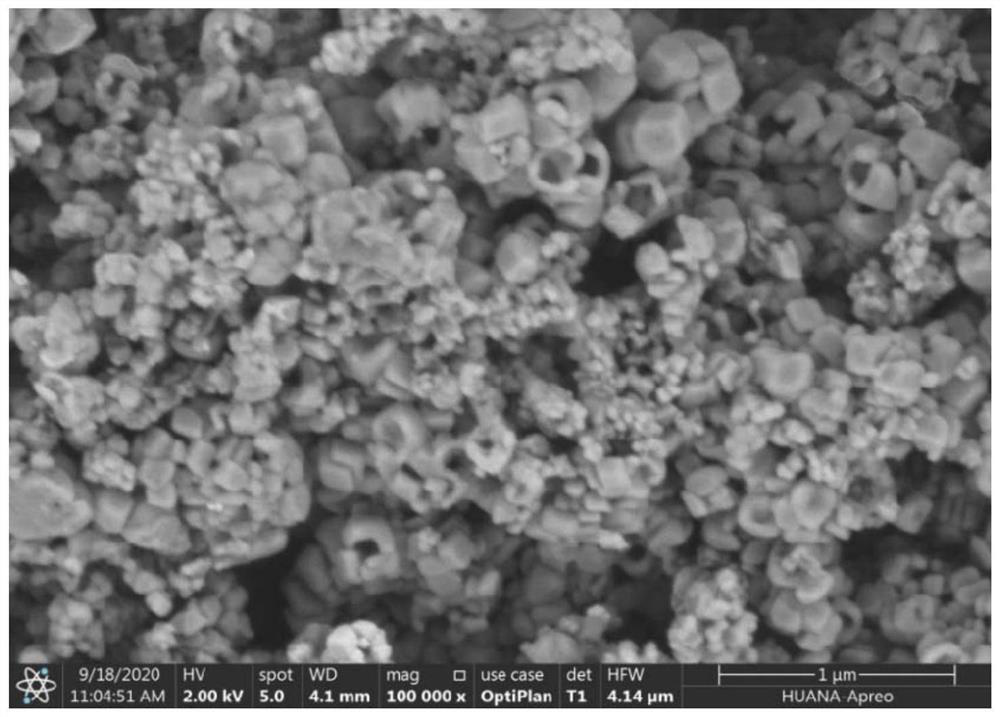

[0038] The ca...

Embodiment 2

[0040] A kind of preparation method of the hollow calcium carbonate particle of stable, particle size controllable, comprises the steps:

[0041] (1) First prepare 400ml of sodium carbonate solution and calcium chloride solution with a concentration of 1mol / L respectively, add barium hydroxide crystal form control agent which is 3% of the mass of calcium carbonate after reaction to the calcium chloride solution, stir and mix evenly ;

[0042] (2) Control the temperature at 35°C and the stirring speed at 900rmb / min. Add the sodium carbonate solution to the calcium chloride through a peristaltic pump at a rate of 50ml / min. After the addition is complete, continue to stir for 5 minutes to obtain a suspension;

[0043] (3) After the reaction, add acetone to the suspension and store it for 3 hours, filter it, dehydrate it by pressure filtration, microwave dry it at 80°C for 3 hours, pulverize it, and classify it to obtain hollow calcium carbonate particles.

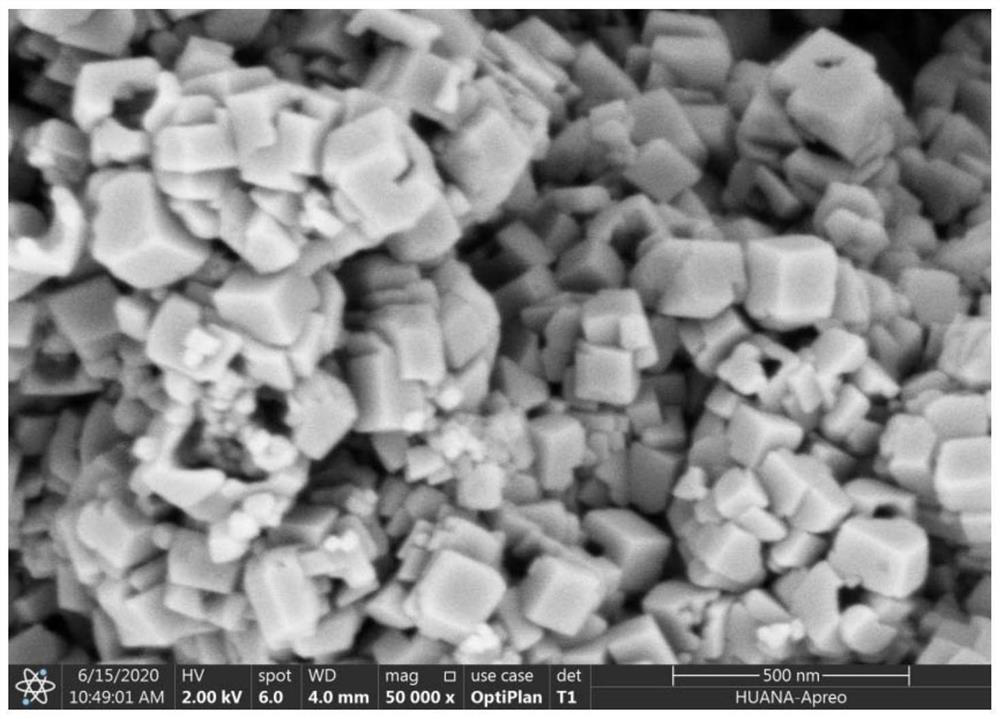

[0044] The calcium ca...

Embodiment 3

[0046] A kind of preparation method of the hollow calcium carbonate particle of stable, particle size controllable, comprises the steps:

[0047] (1) First prepare 400ml of sodium carbonate solution and calcium chloride solution with a concentration of 0.1mol / L respectively, add magnesium hydroxide crystal form control agent which is 5% of the mass of calcium carbonate after reaction to the calcium chloride solution, stir and mix Uniform;

[0048] (2) Control the temperature at 40°C and the stirring speed at 1000rmb / min. Add the sodium carbonate solution to the calcium chloride through a peristaltic pump at a rate of 40ml / min. Continue stirring for 5 minutes after the addition is complete to obtain a suspension;

[0049] (3) After the reaction, add acetone to the suspension and store it for 3 hours, filter, dehydrate by pressing, microwave dry at 110°C for 2 hours, pulverize, and classify to obtain hollow calcium carbonate particles.

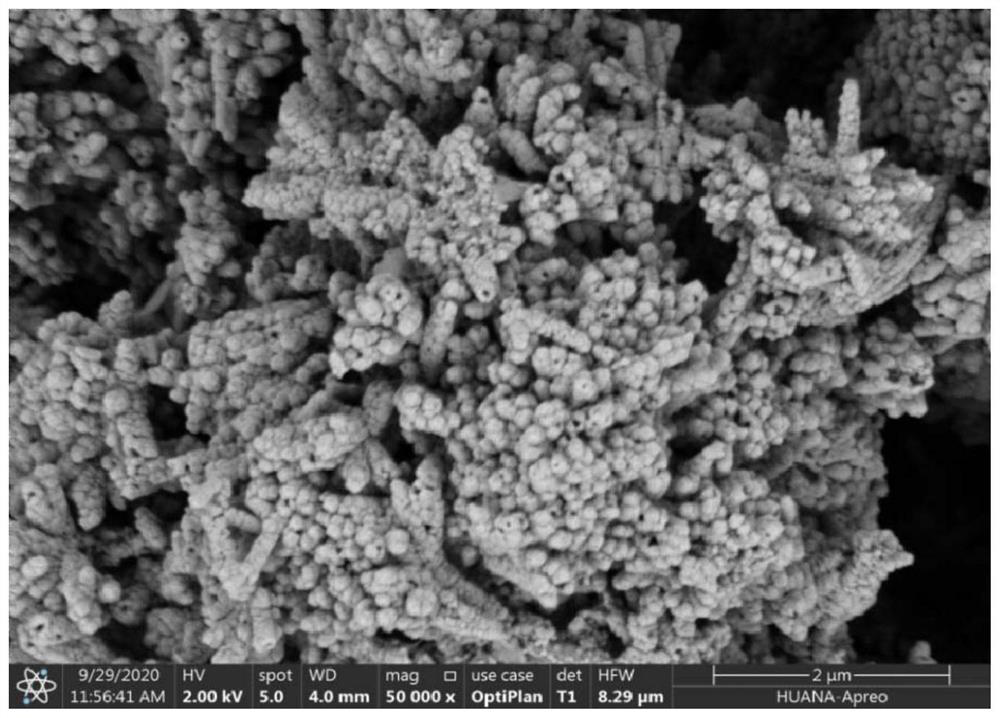

[0050] The calcium carbonate that the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com