Method for removing boron and phosphorus in wastewater by coupling shell powder

A technology for shell powder and wastewater, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. The effect of good biocompatibility, low price and environmental protection, simple treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode 1: This implementation mode is a method for coupling removal of boron and phosphorus in waste water by using shell powder, specifically according to the following steps:

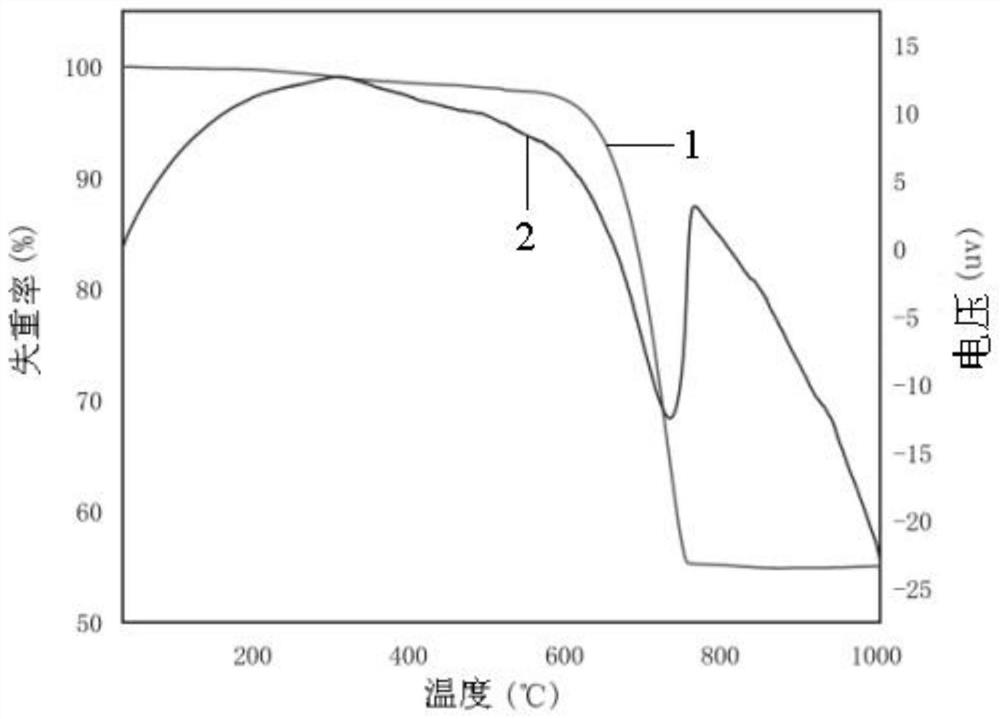

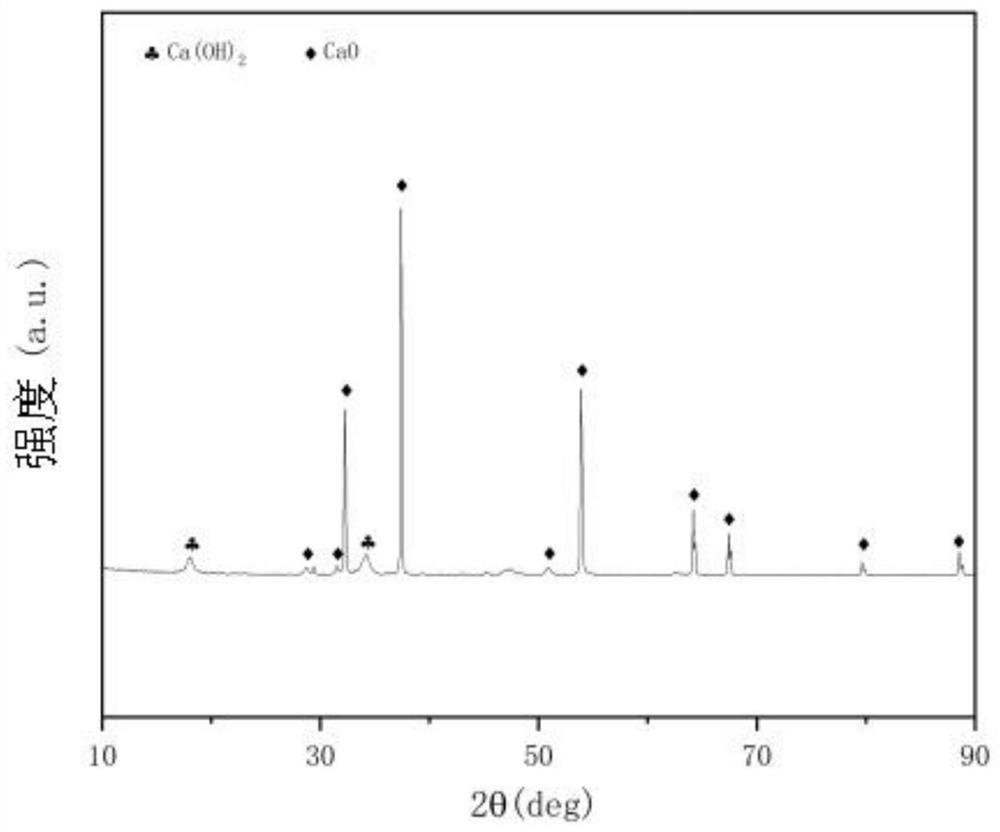

[0026] 1. Clean the oyster shells ultrasonically, place them in an oven, and dry them at 60°C to 65°C; use a pulverizer to crush the dried oyster shells, and sieve them with a mesh size of 100 mesh to 400 mesh. The sieved oyster shell powder is placed in a muffle furnace, calcined at 750°C-1000°C for 3h-4h, and naturally cooled to room temperature to obtain modified shell powder;

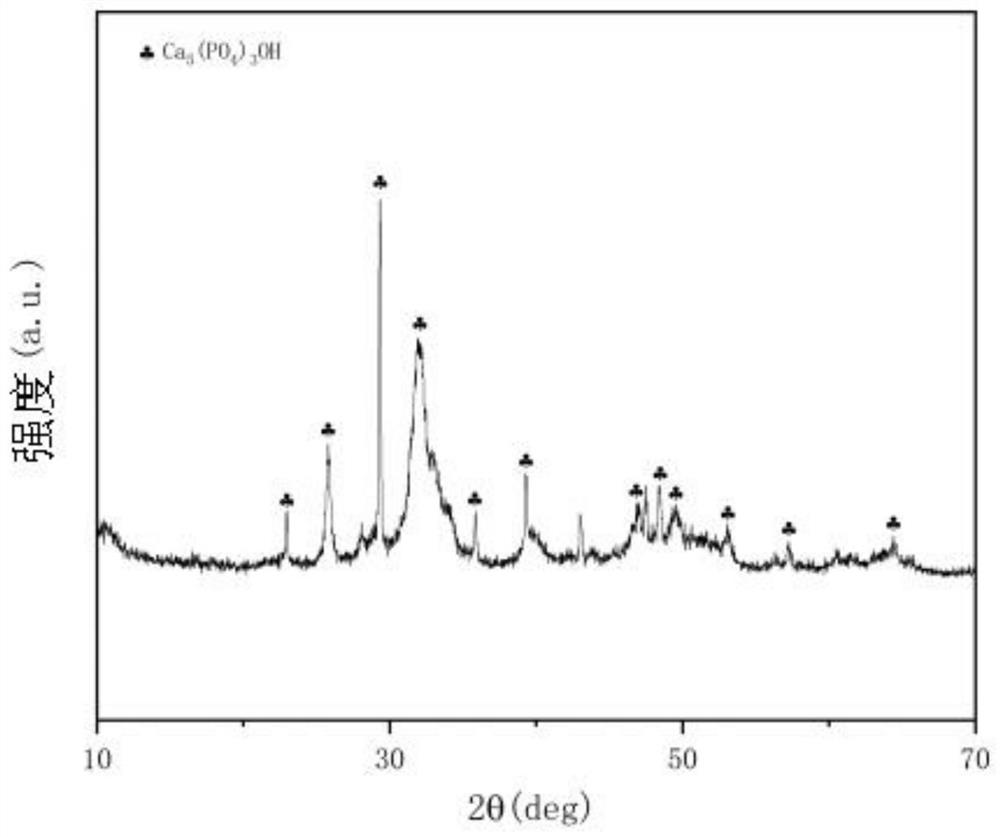

[0027] 2. Add phosphate to the waste water containing boric acid to be treated, stir for 10min to 20min at a speed of 200r / min to 300r / min, and then add the modified shell powder prepared in step 1. Under the condition of 400r / min~500r / min, continue to stir for 5h~6h to complete the coupling removal of boron and phosphorus;

[0028] The molar ratio of the boron element in the waste water contai...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, dry at 60° C. for 24 hours. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the number of mesh in step one is 200 mesh. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com