Optical glass

A technology of optical glass and glass layer, which is applied in optics, optical components, glass molding, etc. It can solve the problems that affect the production rate of optical parts, scratches on the glass surface, and impurities on the surface, so as to improve the protection effect and enhance the Corrosion resistance, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

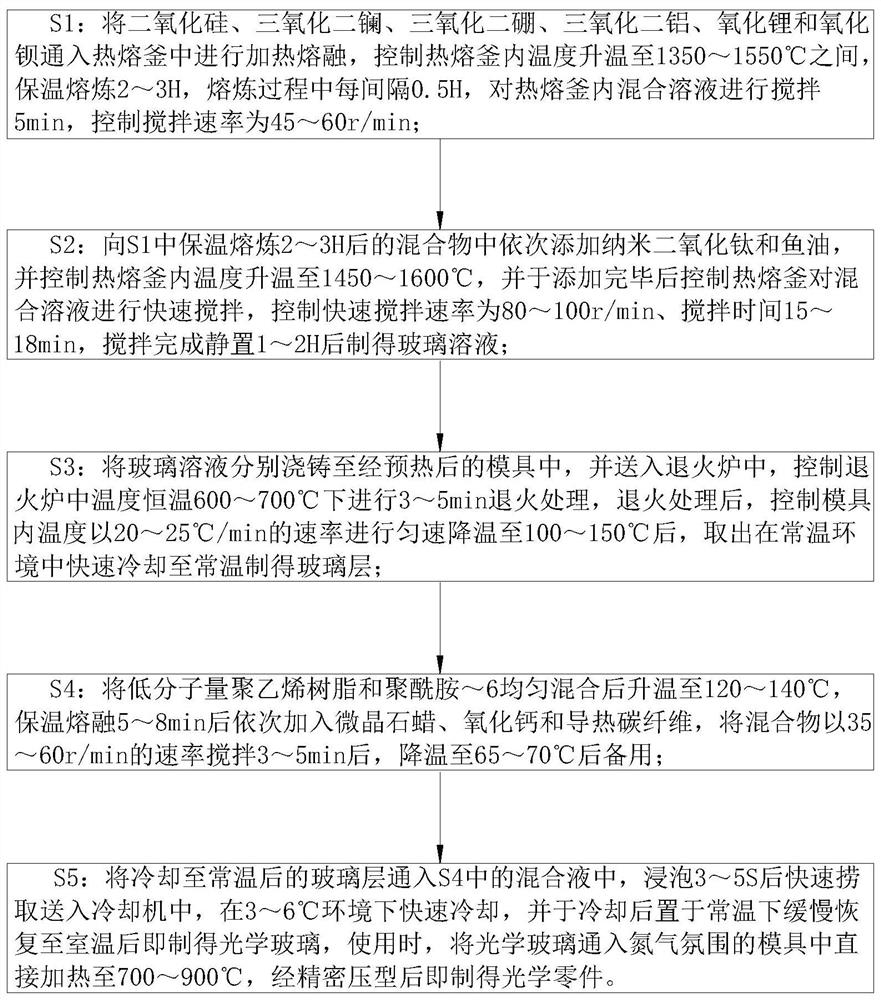

[0031] As an embodiment of the present invention, the preparation method of the optical glass comprises the following steps:

[0032] S1: Pass silicon dioxide, lanthanum trioxide, diboron trioxide, aluminum oxide, lithium oxide and barium oxide into a hot-melt kettle for heating and melting, and control the temperature in the hot-melt kettle to rise to 1350-1550°C During the smelting process, at intervals of 0.5H, the mixed solution in the hot-melt tank was stirred for 5 minutes, and the stirring rate was controlled at 45-60r / min; on the one hand, interval stirring can effectively accelerate the melting of the molten material. At the same time, in the interval of stirring, it can be effectively stood still, so that the impurities in the raw materials can be precipitated and layered, and then a mixed solution with a lower impurity content can be obtained after the smelting is completed;

[0033] S2: Add nano-titanium dioxide and fish oil sequentially to the mixture in S1 after ...

Embodiment 1

[0048] 8-10 parts of silicon dioxide, 24-25 parts of lanthanum trioxide, 16-20 parts of diboron trioxide, 8-12 parts of nano-titanium dioxide, 5-8 parts of aluminum oxide, 1-1.6 parts of barium oxide, 2 ~4 parts fish oil;

[0049] Pass silicon dioxide, lanthanum trioxide, diboron trioxide, aluminum oxide and barium oxide into a hot-melt kettle for heating and melting, control the temperature in the hot-melt kettle to rise to 1350-1550°C, heat-preserve and melt for 2 ~3H, at intervals of 0.5H during the smelting process, stir the mixed solution in the hot-melt kettle for 5 minutes, control the stirring rate to 45-60r / min, add nano-titanium dioxide and fish oil in sequence after heat preservation and melting, and control the temperature rise in the hot-melt kettle to 1450-1600°C, and after the addition is completed, control the hot-melt tank to stir the mixed solution rapidly, control the rapid stirring rate to 80-100r / min, and the stirring time is 15-18min, and after the stirri...

Embodiment 2

[0055] The optical glass includes a glass layer and a protective layer; the protective layer is coated on the outside of the glass layer; the protective layer is made of elastic solid material; the optical glass is composed of the following raw materials:

[0056] 8-10 parts of silicon dioxide, 24-25 parts of lanthanum trioxide, 16-20 parts of diboron trioxide, 8-12 parts of nano-titanium dioxide, 5-8 parts of aluminum oxide, 5-8 parts of lithium oxide, 1 ~1.6 parts of barium oxide, 2~4 parts of fish oil, 8~6 parts of microcrystalline paraffin, 8~10 parts of low molecular weight polyethylene resin, 12~16 parts of polyamide-6, 2~3 parts of calcium oxide and 3~5 parts Thermally conductive carbon fiber;

[0057] Pass silicon dioxide, lanthanum trioxide, diboron trioxide, aluminum oxide, lithium oxide and barium oxide into a hot-melt kettle for heating and melting, and control the temperature in the hot-melt kettle to rise to 1350-1550°C. Heat preservation and smelting for 2 to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com