Bismuth sodium titanate-based relaxor ferroelectric ceramic material with high electric card effect in wide temperature range and high electric card strength at low field and preparation method thereof

A technology based on bismuth sodium titanate and electric card effect, which is applied in the field of electronic functional materials and devices, can solve the problems of lead-containing materials, harmfulness to human body, measured electric card temperature-changing electric card strength, etc., and achieves low preparation cost and wide Service temperature zone, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above bismuth sodium titanate based relaxor ferroelectric ceramic material comprises the following steps:

[0039] S1, select Bi with a purity greater than 99% 2 o 3 、Na 2 CO 3 、K 2 CO 3 , SrCO 3 、TiO 2 and Nb 2 o 5 As the raw material of bismuth sodium titanate-based relaxor ferroelectric ceramics, weigh and mix according to the above general chemical formula to obtain primary mixed powder;

[0040] S2, add absolute ethanol and zirconia grinding balls into the nylon tank as the ball milling medium, then add the primary mixed powder, and transfer to the planetary ball mill for a ball mill for 10-12 hours, and place the material at 80-120°C after discharge drying in a blast drying box to obtain dried powder;

[0041] S3, transferring the dried powder to a muffle furnace, and pre-sintering at 800-900°C (preferably 850°C) for 3-4 hours to obtain the pre-sintered powder;

[0042] S4, using the same method as in step 2) to carry out t...

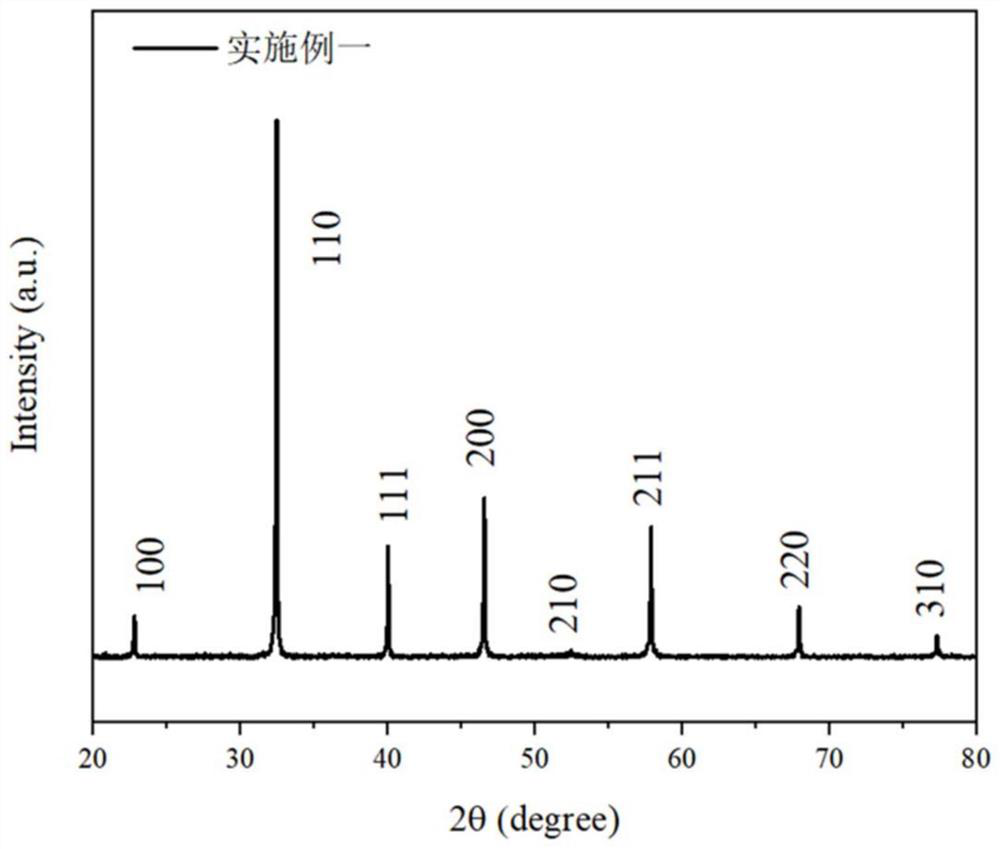

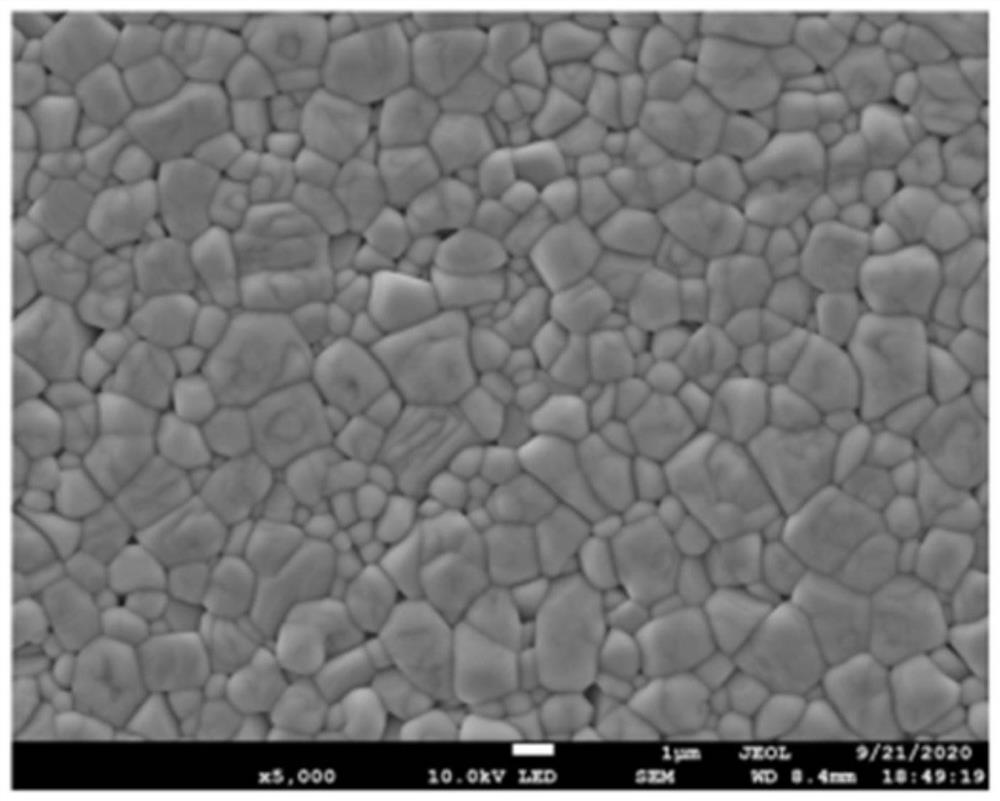

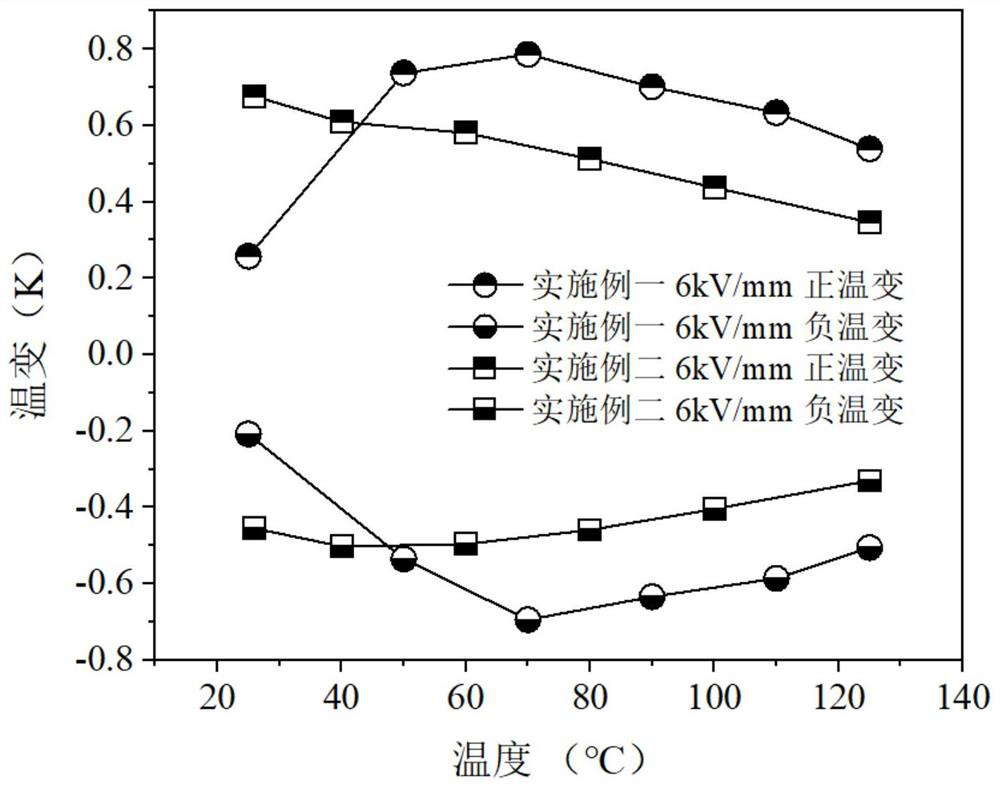

Embodiment 1

[0047] A bismuth sodium titanate-based relaxor ferroelectric ceramic material with a wide temperature range, high electric card effect and high electric card strength, its general chemical formula is (Bi 0.5 Na 0.435 K 0.065 ) 0.92 Sr 0.08 Ti 0.99 Nb 0.01 o 3 , i.e. x=0.005, its preparation method is:

[0048] S1, select Bi with a purity greater than 99% 2 o 3 、Na 2 CO 3 、K 2 CO 3 , SrCO 3 、TiO 2 and Nb 2 o 5 As the raw material of bismuth sodium titanate-based relaxor ferroelectric ceramics, weigh and mix according to the stoichiometric ratio in the above general chemical formula to obtain the primary mixed powder;

[0049] S2, add absolute ethanol and zirconia grinding balls into the nylon tank as the ball milling medium, then add the primary mixed powder, and transfer to the planetary ball mill for 12h primary ball milling, and place the material in a blast at 100°C Dried in a drying box to obtain dried powder;

[0050]S3, put the dried powder into a corun...

Embodiment 2

[0065] A bismuth sodium titanate-based relaxor ferroelectric ceramic material with a wide temperature range, high electric card effect and high electric card strength, its general chemical formula is (Bi 0.5 Na 0.428 K 0.072 ) 0.92 Sr 0.08 Ti 0.99 Nb 0.01 o 3 , namely x=0.012, its preparation method is:

[0066] S1, select Bi with a purity greater than 99% 2 o 3 、Na 2 CO 3 、K 2 CO 3 , SrCO 3 、TiO 2 and Nb 2 o 5 As the raw material of bismuth sodium titanate-based relaxor ferroelectric ceramics, weigh and mix according to the stoichiometric ratio in the above general chemical formula to obtain the primary mixed powder;

[0067] S2, add absolute ethanol and zirconia grinding balls into the nylon tank as the ball milling medium, then add the primary mixed powder, and transfer to the planetary ball mill for 12h primary ball milling, and place the material in a blast at 100°C Dried in a drying box to obtain dried powder;

[0068] S3, put the dried powder into a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com