Silicon carbide single crystal wafer and method for producing silicon carbide single crystal ingot

A technology of silicon carbide single crystal and manufacturing method, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of unfavorable investment budget and time, indistinguishable, etc., and achieve less dislocation and dislocation. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

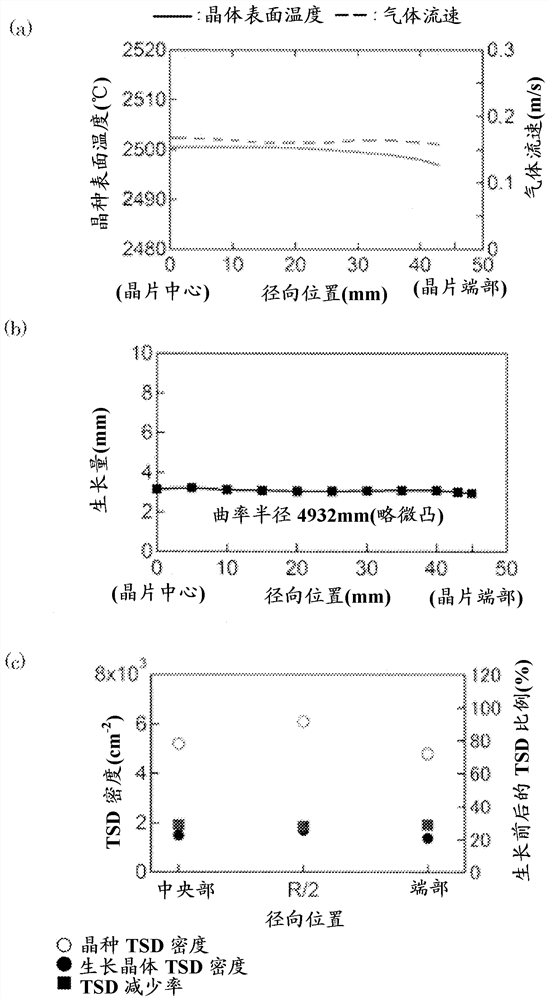

[0099] If so Figure 6 The surface temperature of the seed crystal shown in (a) (a temperature gradient of about 0.06°C / mm) and the flow rate of the source gas allow the SiC single crystal 51 to grow, as Figure 6 As shown in (b), a SiC single crystal with a radius of curvature of 4932 mm and slightly convex (slightly convex) was obtained. The internal stress of a single crystal can be determined by image 3 It is estimated to be below 10Mpa.

[0100] The TSD densities at the center, end, and middle (1 / 2 of the radius R) of the SiC single crystal were measured. show the result in Figure 6 (c).

[0101] As a result, no matter where it is placed, the TSD density is 2000 / cm 2 Below, almost the same number, relative to 5000 seed crystals / cm 2 ~6000pcs / cm 2 , reduced by about 30%, and the distribution is evened out.

Embodiment 2

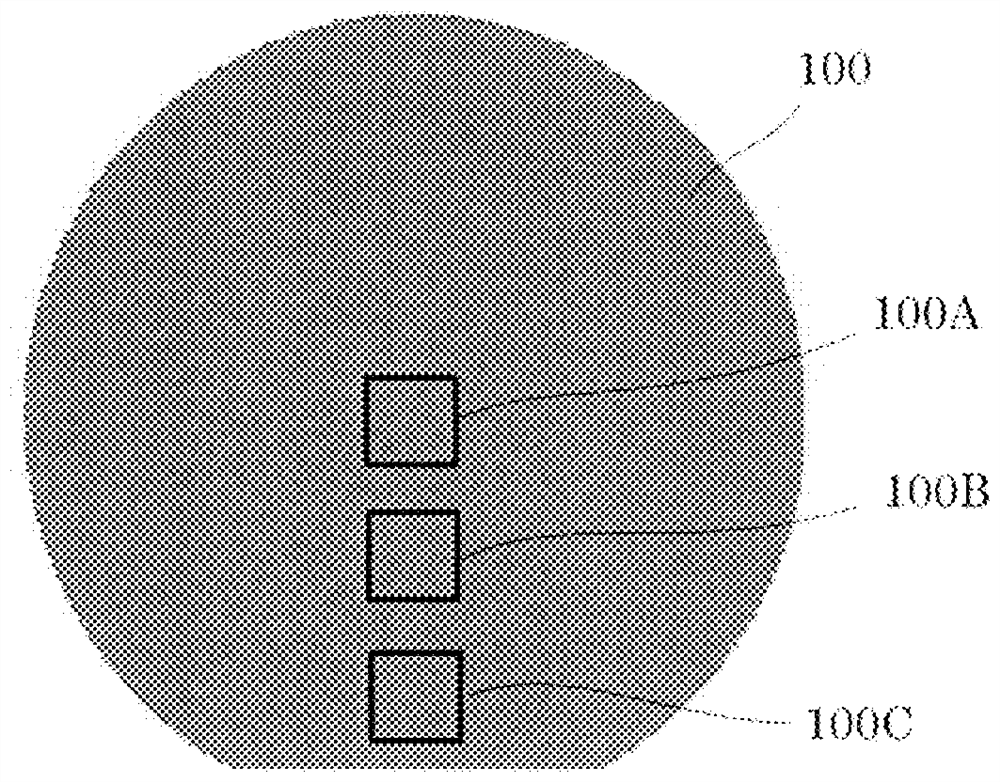

[0107] exist Figure 8 Example 2 is shown. The figure is the result of investigating the dislocation density in the crystal grown by the gas method (2.5 mm growth position) and in the seed crystal. It can be seen that the seed crystal is a crystal grown by the usual growth method, that is, the sublimation method, and the dislocation density distribution is relatively large in the crystal plane. On the other hand, it can be seen that in the crystal grown to 2.5 mm by the gas method, the dislocation density is greatly reduced, and the dislocation density has little uniform variation regardless of the site in the crystal plane. From this result, it is also clear from the examples that the distribution of dislocations becomes uniform in the crystal grown by the gas method.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap